Weld Neck Flanges Supplier

ANSI B16.48 Weld Neck Flanges Exporter, ASME B16.5 Weld Neck Flange, High Quality Weld Neck Flanges, Weld Neck Flanges Suppliers, Flat Faced Weld neck Flange, Weld Neck Raised Face Flanges, Industrial Weld Neck Flanges at Best Price, Austenitic Stainless Steel Weld Neck Flanges, Raised Face Weld neck Flanges, WNFF Flanges, WNRTJ Flanges, MSS SP-44 welding neck Flanges, Weld Neck Flanges Supplier in India

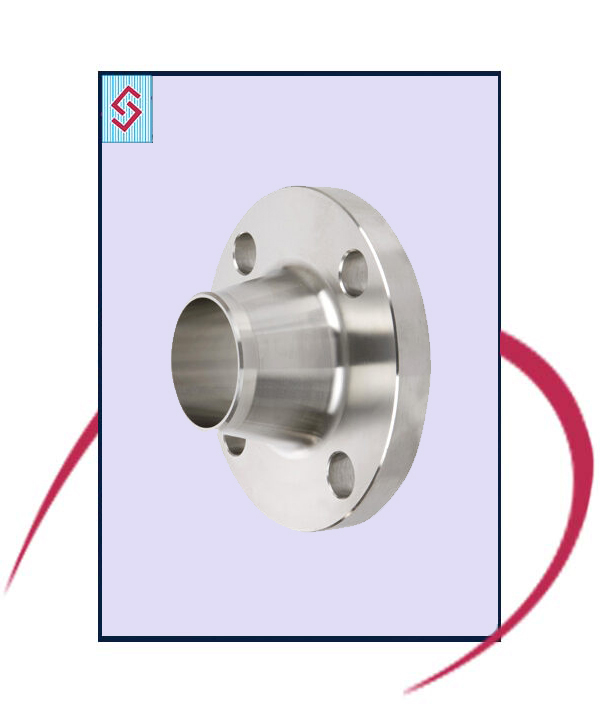

Among the several other types of flanges employed across different industries, the weld neck flanges are the most common and widely used. The structure of the weld neck flanges is distinguished into 2 parts, the hub, and the lower metal ring. The hub is the central portion of the flange which usually contains a hole in the middle, to allow the flow of the pipe to pass through them. Whereas, the metal ring surrounding the hub contains the bolt holes to be fixed around the edge of the pipe end. When we look into the hub of the weld neck flanges, they are raised above the metal ring plane and its dimension varies according to the pipe it connects to. This enables there to be two major types of weld neck flanges, the first one is the regular type, used to connect pipes in the piping system and the latter is characterized by a long neck, making it unsuitable to be used with pipes and are, therefore, restricted to process plants.

Inconel Weld Neck Flanges, Carbon Steel Weld Neck Flanges, Duplex Steel Weld Neck Flange, Nickel Alloy Weld Neck Flange, Hastelloy Weld Neck Flanges, Monel Weld Neck Flanges, Alloy Steel Weld Neck Flange, Incoloy Weld Neck Flanges, Stainless Steel Weld Neck Flange, ANSI B16.47 Series A & B Weld Neck Flanges, Super Duplex Steel Weld Neck Flanges, Titanium Weld Neck Flange, Weld Neck Flanges Manufacturer in Mumbai.

The major reason for the weld neck flanges to be commonly employed in several applications is the plethora of properties it provides the system with. The weld neck flanges have demonstrated their strength against high pressure in a number of elevated pressure situations. This toughness attributed to the flanges is also useful for them when faced with mechanical strain as well. Along with high pressure, the weld neck flanges have also been known to withstand soaring temperature conditions with efficiency. In fact, these flanges work remarkably in aggressive operating conditions as such, as compared to the other types of flanges. These flanges also display resistance against corrosion caused by the liquid and gaseous components inhabited by the pipes.

Standard Specification

- Size

- Dimensions

- Standard

- Pressure Class / Rating

- Flange Connect Type/ Face Type

Types of Weld Neck Flanges

- Stainless Steel Flat Face Weld Neck Flanges

- SS Weld Neck Flange Supplier

- Duplex Steel Weld Neck Flanges

- Super Duplex Steel WNFF Stockist

- SS Weld Neck Flange Manufacturer

- 254 SMO Weld Neck Raised Face Flange

- ANSI B16.5 SS Weld Neck Flange Exporter

- ASME SA182 Weld Neck Flanges

- Stainless Steel 304 Weld Neck Flanges

- Stainless Steel WNRTJ Flanges

- SS Weld Neck Raised Face Flanges

- Carbon Steel IS 2062 Weld Neck Flanges

- Carbon Steel Ring Type Joint Weld Neck Flanges

- CS Weld Neck Raised Face Flanges

- Alloy Steel Flat Face Weld Neck Flanges

- Chrome Moly WNFF Supplier

- A36 CS Weld Neck Flanges

- Alloy Steel F5 Weld Neck Flange Stockist

- ASME SA105 CS Weld Neck Flanges

- ASTM A694 F42 WNFF Manufacturer

- Low Temperature Carbon steel Weld Neck Flange

- ANSI B16.5 CS Weld Neck Flange Exporter

- Titanium Weld Neck Flanges

- Alloy 20 RFWN Stockist

- Tantalum RFWN Manufacturer

- High Nickel Alloy Weld Neck Flange

- Monel Ring Type Joint Weld Neck Flanges

- Inconel Weld Neck Raised Face Flanges

- Incoloy Flat Face Weld Neck Flanges

- Hastelloy Weld Neck Flange Supplier

- ASME SB564 High Nickel Alloy Weld Neck Flanges

- Nickel Alloy 200 Weld Neck Flanges

- ANSI B16.5 Alloy Weld Neck Flange Exporter

Other Types Weld Neck Flanges

- Monel 400 Weld Neck Flanges Manufacturer

- 600 LBS Weld Neck Flanges

- High Nickel Alloy Weld Neck Flanges

- Suppliers of SS Weld Neck Flanges

- ANSI B16.5 200 Nickel Alloy Weld Neck Flange

- ANSI B16.48 Weld Neck Flange Distributors

- BS4504 Weld Neck Flanges Supplier in India

- 2500 LBS Weld Neck Flange Stock

- High Quality Weld Neck Flanges

- ANSI B16.47 Weld Neck Flanges in Mumbai

- Steel Weld Neck Flanges Dealer in India

- ASTM A182 F304 Weld Neck Flange

- SS PN40 Weld Neck Flange Manufacturer

- Low Temperature Carbon steel Weld Neck Flanges

- 1500 LBS Weld Neck Flanges Stockist in Mumbai

- Carbon Steel Weld Neck Flange

- Weld Neck Flange Dimensions

- ASME B16.5 Weld Neck Flanges Stockholder

- 900 LBS Weld Neck Flanges Exporter

- PN16 Weld Neck Flanges Exporters

Weld Neck Flanges Application Industries

Searches Related to Weld Neck Flanges

We Export Weld Neck Flanges to Following Destinations

Pakistan, Argentina, Azerbaijan, South Africa, Portugal, Italy, Ghana, Mexico, Vietnam, Bhutan, United Arab Emirates, Romania, Hong Kong, Switzerland, Taiwan, Afghanistan, Qatar, Iran, South Korea, United States, Spain, Croatia, France, Brazil, Kazakhstan, Japan, Colombia, Bulgaria, Lithuania, Nigeria, Nigeria, Iraq, Oman, Trinidad & Tobago, Sri Lanka, Kuwait, Tunisia, Poland, Ecuador, Yemen, Venezuela, Turkey, Israel, Gabon, Austria, Lebanon, New Zealand, Saudi Arabia, Peru, Greece, Algeria, Libya, United Kingdom, Slovakia, Sweden, Norway, Chile, Kenya, Bahrain, Australia, Costa Rica, Mexico, Angola, Serbia, Jordan, Indonesia, Iran, China, Singapore, Morocco, Denmark, Hungary, Estonia, Malaysia, Poland, Czech Republic, Thailand, Mongolia, Russia, Philippines, Ukraine, Bolivia, Chile, Belarus, Egypt, Bangladesh, Finland, Belgium, Canada, Netherlands.

Kanpur, Thiruvananthapuram, Edmonton, Dallas, Caracas, New Delhi, Bhopal, Seoul, Houston, Faridabad, Rajkot, Ho Chi Minh City, Haryana, Coimbatore, Montreal, Kuala Lumpur, Madrid, Al Khobar, Rio de Janeiro, Port-of-Spain, Ernakulam, Bogota, Visakhapatnam, Toronto, Milan, Granada, Algiers, Jakarta, Chennai, Doha, Santiago, Tehran, Ulsan, Howrah, Vung Tau, Jaipur, Atyrau, Geoje-si, Gurgaon, Nashik, Ranchi, Pune, La Victoria, Los Angeles, Petaling Jaya, Cairo, Hanoi, Riyadh, Lahore, Colombo, Aberdeen, Mumbai, New York, Secunderabad, Muscat, Jeddah, Thane, Baroda, Ludhiana, Ankara, Calgary, Brisbane, Navi Mumbai, Al Jubail, Ahvaz, Kuwait City, Istanbul, Ahmedabad, Indore, Courbevoie, Pimpri-Chinchwad, Hyderabad, Dubai, Jamshedpur, Manama, Sydney, Melbourne, Chandigarh, Dammam, Lagos, Surat, Kolkata, Nagpur, Bengaluru, Perth, Chiyoda, Bangkok, Sharjah, Abu Dhabi, Gimhae-si, Noida, Vadodara, Busan.