Stainless Steel 904L Forged Fittings Supplier

ASTM A182 F904L FORGED FITTINGS SUPPLIERS, SS 904L FORGED FITTINGS, STAINLESS STEEL 904L INDUSTRIAL FORGED FITTINGS AT BEST PRICE, STAINLESS STEEL N08904 FORGED FITTING, 904L STAINLESS STEEL FORGED FITTINGS, STAINLESS STEEL 904L FORGED FITTINGS, AUSTENITIC STAINLESS STEEL 904L FORGED FITTINGS, 904L STAINLESS STEEL FORGED FITTINGS EXPORTER, STAINLESS STEEL 1.4539 FORGED FITTING, ASME SA182 STAINLESS STEEL 904L HIGH PRESSURE FORGED FITTINGS SUPPLIER IN INDIA.

- What is Stainless Steel 904L Forged Fittings

- Standard Specification For Stainless Steel 904L Forged Fittings

- Stainless Steel 904L Forged Fittings Equivalent Grades

- Types of Stainless Steel 904L Forged Fittings

- Stainless Steel 904L Socket Weld Fitting Chemical Composition

- Mechanical Properties of SS 904L Forged Fittings

- Other Types of 904L Stainless Steel Threaded Fittings Ready Stock

- Stainless Steel Grade 904L Forged Fittings Applications

- Searches Related to Stainless Steel 904L Screwed Fittings

- Export Destinations for Stainless Steel 904L Forged Fittings

Steel sales Co is considered as one of the reliable name in the market when it’s about stainless steel 904L forged fittings. Steel sales Co is a manufacturer, stockiest, supplier and distributor of various metals and alloy products based in Mumbai, India. supplying goods and products to many corners of the India. best quality raw material is used and handled by skilled and trained staff using some of the advanced techniques and modern machineries.

Stainless steel 904L forged fittings is considered as super austenitic alloy product having wide application in various fields. Stainless steel 904L has great formability and weldability, tough it’s not a stabilized alloy. Also stainless steel 904L forged fittings has excellent resistance to stress corrosion cracking, remarkable resistance to intergranular corrosion and also it is highly resistant to crevice corrosion. Stainless steel 904L consist of molybdenum addition, also stainless steel 904L is known by other names such as: DIN 1.4539, SUS 904L etc. also its low carbon component plays a remarkable role in improving sensitization resistance. And also it is corrosion resistant to all type of concentration of sulphuric acid due to its copper addition. To modify stainless steel into various shapes and size and also in order to harden it properly it requires advanced machinery and specialized equipment.

SS 904L FORGED CROSS, STAINLESS STEEL 904L SOCKET WELD FITTINGS, STAINLESS STEEL 904L THREADED FITTINGS, SS 904L FORGED ELBOW, SS 904L THREADED NIPPLE STOCKIST, ANSI B16.11 SS 904L FORGED FITTINGS, STAINLESS STEEL F904L FORGED TEES, SS 904L SCREWED FITTINGS, STAINLESS STEEL 904L BUSHING, STAINLESS STEEL 904L COUPLING, SS F904L FORGED UNION, SS 904L FORGED CAP, 904L SS FORGED PLUGS, STAINLESS STEEL 904L FORGED FITTINGS MANUFACTURER IN MUMBAI.

Stainless steel 904L is normally applicable in gas scrubbing plants, plants which processes sulphuric acid, acetic acid, as well as phosphoric acid. It also has wide application in seawater cooling devices,oil refinery components, paper and pulp processing industries, wiring in electrical precipitators etc.

Standard Specification

- Specifications

- Size

- Dimensions

- Types

- Pressure Rating

Socket-weld End-3000/ 6000/ 9000lbs

- Thread

- Specialized Manufacturer

Stainless Steel 904L Screwed Fittings Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | KS | AFNOR | EN |

| SS 904L | 1.4539 | N08904 | SUS 904L | 904S13 | STS 317J5L | Z2 NCDU 25-20 | X1NiCrMoCu25-20-5 |

Types of Stainless Steel 904L Forged Fittings

Forged Elbows

- ANSI B16.11 SS 904L Forged Elbows

- SS 1.4539 Forged Elbows

- ASTM A182 SS 904L BSPT Threaded Elbows Manufacturer

- SS 904L 90 Deg Forged Elbows

- 904L SS 90 Degree Forged Elbow Exporter

- UNS N08904 Forged Elbows

- SS 904L 45 Deg Threaded Elbows

- 904L Stainless Steel Forged Elbows Supplier

- Stainless Steel N08904 Forged Elbow

- SS 904L Socket Weld Elbows Stockist

- Stainless Steel 904L NPT Screwed Elbow

- ASME SA182 F904L Forged Elbows

Forged Tee

- ASTM A182 F904L Forged Tee

- UNS N08904 Forged Tee

- Stainless Steel 1.4539 Forged Tee

- SS 904L NPT Threaded Forged Tee

- ANSI B16.11 SS 904L Forged Tee

- SS 904L Socket Weld Tee Stockist

- SS 1.4539 Forged Tee Manufacturer

- ASME SA182 SS 904L Forged Reducing Tees

- ASME SA182 SS 904L Forged Tee

- SS 904L Equal Forged Tee

- SS N08904 Screwed Tee

- 904L Stainless Steel BSPT Threaded Tee Supplier

- 904L SS Unequal Forged Tee Exporter

Forged Cross

- SS N08904 Forged Cross

- ASME SA182 SS 904L Forged Cross

- 904L Stainless Steel Forged Cross Supplier

- 904L SS Unequal Forged Cross Exporter

- UNS N08904 NPT Threaded Cross

- SS 1.4539 Equal Forged Cross

- SS 904L BSPT Screwed Forged Cross

- Stainless Steel 904L Forged Reducing Cross

- Stainless Steel 1.4539 Forged Cross

- SS 904L Socket Weld Cross Stockist

- ASTM A182 F904L Forged Cross

- ANSI B16.11 SS 904L Forged Cross

Coupling

- ASTM A182 F904L Couplings

- UNS N08904 Couplings

- 904L Stainless Steel Couplings Supplier

- ANSI B16.11 SS 904L Forged Couplings

- SS 904L Socket Weld Couplings Stockist

- SS N08904 Couplings Manufacturer

- Stainless Steel 1.4539 BSPT Threaded Coupling

- SS 904L NPT Screwed Couplings

- 904L Stainless Steel Threaded Coupling

- Stainless Steel 904L Half Coupling

- 904L SS Full Coupling Exporter

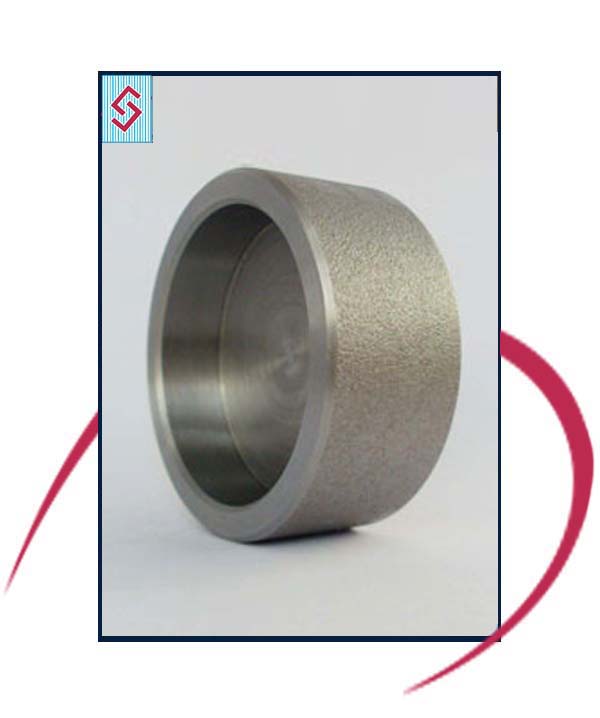

Forged Cap

- ASTM A182 F904L Forged Caps

- ANSI B16.11 SS 904L Forged Pipe End Cap

- Stainless Steel 904L Screwed Caps

- 904L Stainless Steel Forged Caps Supplier

- ASME SA182 SS 904L Forged End Caps

- SS 904L Socket Weld End Pipe Caps Stockist

- SS 1.4539 BSPT Threaded Pipe Caps

- UNS N08904 Forged Caps

- 904L SS NPT Threaded Caps

- Stainless Steel 1.4539 Forged Cap

- 904L SS Forged End Cap Exporter

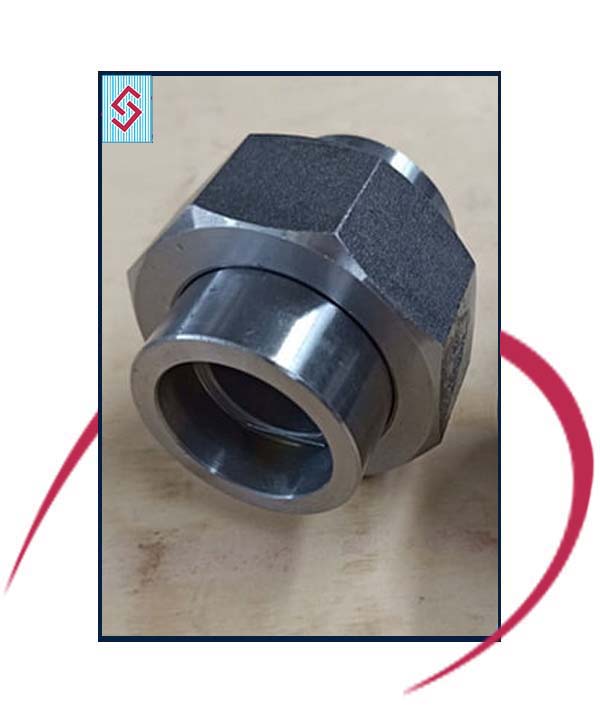

Union

- ASTM A182 F904L Unions

- ANSI B16.11 SS 904L Forged Union

- ASME SA182 SS 904L Unions

- 904L SS Hex Head Union Exporter

- SS N08904 Screwed Union

- SS 1.4539 NPT Threaded Unions

- 904L Stainless Steel Unions Supplier

- UNS N08904 Hex Unions

- SS 1.4539 BSPT Threaded Union

- Stainless Steel 904L Unions Manufacturer

- SS 904L Socket Weld Unions Stockist

Plug

- ASME SA182 SS 904L Plugs

- 904L SS Hex Head Plug Exporter

- ASTM A182 F904L Plugs

- ANSI B16.11 SS 904L Forged Plug

- SS 904L BSPT Threaded Plugs Manufacturer

- SS 904L Square Plugs Stockist

- UNS N08904 Round Head Plugs

- SS 1.4539 Plug

- 904L Stainless Steel Plugs Supplier

- SS N08904 Screwed Plug

- SS 1.4539 NPT Threaded Plugs

Bushing

- ASTM A182 F904L Bushings

- ANSI B16.11 SS 904L Forged Bushing

- SS 1.4539 NPT Threaded Bushings Manufacturer

- SS 904L BSPT Screwed Bushings Stockist

- 904L SS Bushing Exporter

- SS N08904 Hex Head Bushing

- SS 1.4539 Threaded Bushings

- 904L Stainless Steel Bushings Supplier

- ASME SA182 SS 904L Bushings

- UNS N08904 Bushings

- SS 1.4539 Hex Head Bushing

Forged Nipple

- ANSI B16.11 SS 904L Forged Nipple

- SS 904L Threaded Nipples Stockist

- UNS N08904 BSPT Threaded Swage Nipples

- SS 1.4539 Forged Nipple

- ASME SA182 SS 904L Forged Nipples

- 904L SS Socket Weld Nipple Exporter

- ASTM A182 F904L Forged Nipples

- 904L Stainless Steel Forged Nipples Supplier

- SS 1.4539 Forged Nipples Manufacturer

- SS N08904 Forged Nipple

- SS 1.4539 NPT Screwed Nipples

ASTM A182 Stainless Steel 904L Forged Fittings Chemical Composition

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Cu |

| SS 904L | 0.020 max | 2.00 max | 1.00 max | 0.040 max | 0.030 max | 19.00 – 23.00 | 4.00 – 5.00 max | 23.00 – 28.00 | 1.00 – 2.00 |

Stainless Steel 904L Socket Weld Fittings Mechanical Properties

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 7.95 g/cm3 | 1350 °C (2460 °F) | Psi – 71000 , MPa – 490 | Psi – 32000 , MPa – 220 | 35 % |

Other Types Stainless Steel 904L Forged Fittings

- Stainless Steel 904L Forged Union

- UNS N08904 NPT Threaded Tee in Mumbai

- SS 904L Forged Socket weld Fittings

- SS 904L Unequal Cross Supplier in India

- SS 904L 90 Degree Threaded Elbow Manufacturer

- SS 904L 3000LB Threaded Fittings

- SS Grade F904L Screwed Plug

- UNS N08904 High Pressure Forged Fittings

- SS 1.4539 Street Elbow Dealer in India

- ASTM A182 F904L 45° Threaded Elbow

- Stainless Steel 904L BSPP Screwed Coupling

- A182 Stainless Steel 904L Socket weld Pipe Cap

- SS 904L Forged Threaded Hex Nipple

- SS 904L Swage Nipple Manufacturer

- UNS N08904 Threaded Bushing Exporters

- SS 904L Half Coupling Stockholder

- 904L Stainless Steel Threaded Cross Supplier

- SS 904L NPT Threaded Square Plug

- SS N08904 Socket Weld Cross

- SS 904L High Pressure Forged Fittings

- Stainless Steel 904L Forged Tee

- SS 904L BSPT Screwed Union Stockist in Mumbai

Stainless Steel 904L Threaded Fittings Application Industries

Searches related to Stainless Steel 904L Forged Fittings

We Export SS 904L Forged Fittings to Following Destinations