Stainless Steel 904L Flanges SUPPLIER

ASME SA182 904L STAINLESS STEEL FLANGES , SS A182 F904L FLANGES, UNS N08904 FLANGE, 904L STAINLESS STEEL FLANGES, SS N08904 FLANGE, STAINLESS STEEL 1.4539 FLANGES EXPORTER, ASTM A182 F904L FLANGES SUPPLIERS, STAINLESS STEEL 904L INDUSTRIAL FLANGES AT BEST PRICE, 904L SS PIPE FLANGES EXPORTER, STAINLESS STEEL 904L FLANGES, AUSTENITIC STAINLESS STEEL 904L FLANGES SUPPLIER IN INDIA.

- What is Stainless Steel 904L Flanges

- Standard Specification For Stainless Steel 904L Flanges

- Stainless Steel 904L Flanges Equivalent Grades

- Types of Stainless Steel 904L Flanges

- Stainless Steel 904L Flange Chemical Composition

- Mechanical Properties of SS 904L Flanges

- Other Types of 904L Stainless Steel Flanges Ready Stock

- Stainless Steel Grade 904L Flanges Applications

- Searches Related to Stainless Steel 904L Flanges

- Export Destinations for Stainless Steel 904L Flanges

Steel Sales Co is an established manufacturer and exporter of the Stainless Steel 904L Flanges. We, at Steel Sales Co, are involved in the stocking of these Stainless Steel 904L Flanges for the forthcoming requisitions of our clients. We also are associated with the huge steel magnates in the iron and steel industry for the distribution of these Stainless Steel 904L Flanges manufactured by them. We are also available for our patrons if they require these Stainless Steel 904L Flanges to be tailor-made as per their desired sizes, shapes, surface finishes, and all the other dimension-related aspects that can be altered according to their requisition.

The Stainless Steel 904L grade that we formulate to manufacture these Stainless Steel 904L Flanges consist of chemical elements that are significantly selected and installed on the basis of the applications of the flanges and essentially the mechanical properties that are important for the flanges. Thus, in the chemical composition of the SS 904L Flanges, there is a basic combination of stainless steel, that is chromium, and nickel. Apart from them, there is an addition of the element of molybdenum which has an amazing set of elemental structures and great features to assist the flanges too. These SS 904L Flanges possess an improved amount of resistance against corrosion when compared to the stainless steel grades of 316L and 317L. The SS 904L belongs to the austenitic group of stainless steel alloy as the molybdenum and copper contents are higher, leading to the SS 904L Flanges gaining resistance to harsh acids like sulphuric acid and nitric acid. These SS 904L Flanges are capable of combating the corrosive cracking caused by the stress and crevice corrosion too, on the material. The SS 904L Flanges exhibit a good resistivity when it comes to the pitting conditions in the chloride atmospheres. These SS 904L Flanges are ultimately well at the forming and welding processes.

STAINLESS STEEL 904L LAP JOINT FLANGES, SS 904L BLIND FLANGE, SS 904L THREADED / SCREWED FLANGES, STAINLESS STEEL 904L FLAT FACE FLANGES, 904L STAINLESS STEEL RAISED FACE (RF) FLANGES, SS 904L BLRF FLANGE, SS 904L SPECTACLE BLIND FLANGE STOCKIST, SS 904L SORF FLANGES, SS 904L WELD NECK FLANGES, STAINLESS STEEL 904L FLAT FACE (FF) FLANGES, STAINLESS STEEL 904L SOCKET WELD FLANGES, SS 904L SLIP ON FLANGES, SS 904L RING TYPE JOINT (RTJ) FLANGES, SS 904L FORGED FLANGES, STAINLESS STEEL 904L FLANGES MANUFACTURER IN MUMBAI.

Our Stainless Steel 904L Flanges are fabricated mostly for industrial purposes because of their display of good tensile and yield strength. Hence, some of the many industries where these Stainless Steel 904L Flanges are utilized are gas and oil pipelining, plumbing, systems pf water supply, paper, and pulp industry, food processing, and several kinds of chemical industries too.

Standard Specification

- Specifications

- Size

- Dimensions

- Standard

- Pressure Class / Rating

- Flange Connect Type/ Face Type

- Specialized manufacturer of

Stainless Steel 904L Flanges Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | KS | AFNOR | EN |

| SS 904L | 1.4539 | N08904 | SUS 904L | 904S13 | STS 317J5L | Z2 NCDU 25-20 | X1NiCrMoCu25-20-5 |

Types of Stainless Steel 904L Flanges

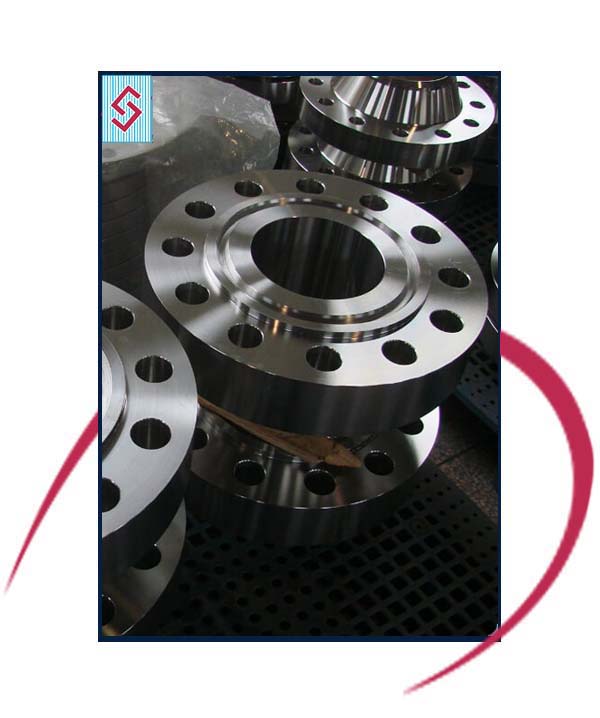

Slip On Flanges

- 904L SS Raised Face Slip on Flange Exporter

- Stainless Steel 904L Slip On Flange

- SS 904L SORF Flanges

- 904L Stainless Steel Slip On Flanges Supplier

- Stainless Steel 1.4539 Slip On Flange

- SS 904L Slip on Raised Face Flange Stockist

- SS 904L SOFF Flanges

- SS 904L SORTJ Flange

- SS 904L RFSO Flanges

- ASME SA182 SS 904L Slip On Flanges

- UNS N08904 Slip On Flanges

- ASTM A182 F904L Slip On Flanges Manufacturer

- SS N08904 Slip On Flanges

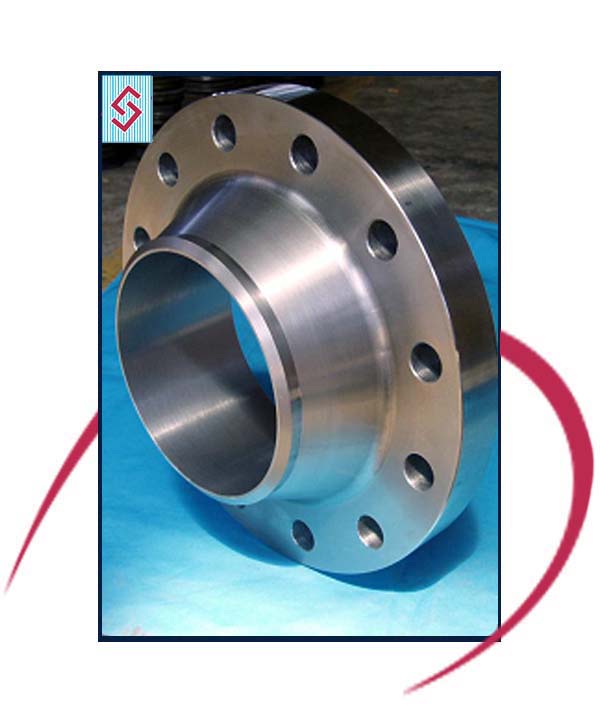

Weld Neck Flanges

- 904L Stainless Steel Weld Neck Flanges Supplier

- 904L SS Welding Neck Flange Exporter

- SS 904L WNRF Flanges

- Stainless Steel 1.4539 Weld Neck Flange

- ASME SA182 SS 904L Weld Neck Flanges

- UNS N08904 Weld Neck Flanges

- SS 904L Weld Neck Flanges

- SS 904L WNFF Flange Manufacturer

- SS 904L RFWN Flange

- SS 904L WNRTJ Flange

- ASTM A182 F904L Weld Neck Flanges

- SS 904L Weld Neck Flanges Stockist

- ASME SA182 SS 904L Weld Neck Flanges

- SS 1.4539 Welding Neck Flanges

- SS N08904 Weld Neck Flanges

Socket Weld Flanges

- 904L Stainless Steel Socket Weld Flanges Supplier

- Stainless Steel 1.4539 Socket Weld Flange

- SS 904L Socket Weld Flanges Stockist

- 904L SS Socket Weld Flange Exporter

- ASME SA182 SS 904L Socket Weld Flanges

- Stainless Steel 904L SW Flange

- 904L SS SWRTJ Flanges

- 904L Stainless Steel SWRF Flanges

- SS 904L SWFF Flange

- Stainless Steel 904L RFSW Flanges

- ASTM A182 F904L Socket Weld Flanges in India

- SS N08904 Socket Weld Flanges

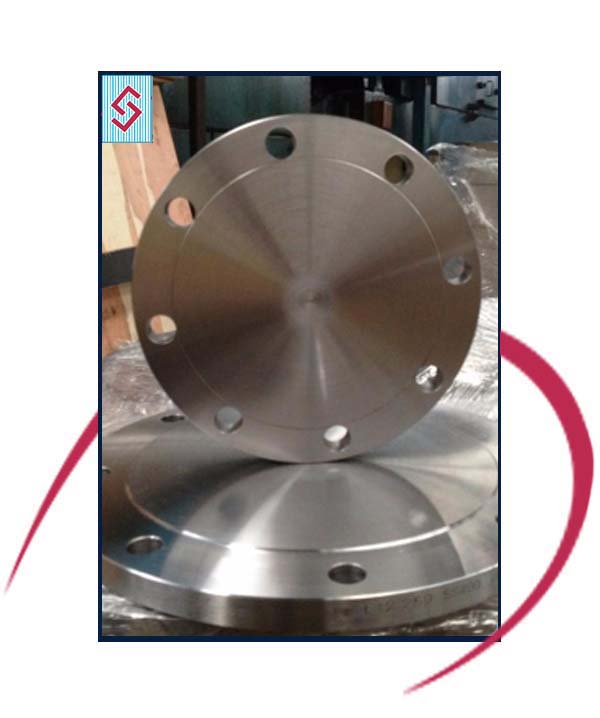

Blind Flanges

- 904L SS Raised Face Blind Flange Exporter

- Stainless Steel 904L Blind Flange

- SS 904L Blind Flanges Stockist

- 904L Stainless Steel Blind Flanges Supplier

- Stainless Steel 1.4539 Blind Flange

- SS N08904 Blind Flanges Manufacturer

- SS 904L BLFF Flange

- SS 904L BLRF Flanges

- SS 904L BLRTJ Flange

- SS 904L RFBL Flanges

- ASTM A182 SS F904L Blind Flanges

Ring Type Joint Flanges

- Stainless Steel 1.4539 Ring Type Joint Flange

- 904L SS Ring Type Joint Flange Exporter

- SS 904L RTJ Flanges Stockist

- ASTM A182 SS 904L Ring Type Joint Flanges

- ASME SA182 SS 904L Ring Type Joint Flanges

- ASTM A182 F904L Stainless Steel RTJ Flanges

- 904L Stainless Steel Ring Type Joint Flanges Supplier

- SS 1.4539 Ring Type Joint Flanges

- UNS N08904 RTJ Flanges

Spectacle Blind Flanges

- ASTM A182 F904L Spectacle Blind Flanges

- Stainless Steel 1.4539 Spectacle Blind Flange

- 904L SS Spectacle Blind Flange Exporter

- ASME SA182 SS 904L Spectacle Blind Flanges

- SS N08904 Spectacle Blind Flanges

- 904L Stainless Steel Spectacle Blind Flanges Supplier

- SS 1.4539 Spectacle Blind Flanges

- SS 904L Spectacle Blind Flanges Stockist

- SUS 904L Spectacle Blind Flanges

Long Weld Neck Flanges

- ASTM A182 SS 904L Long Weld Neck Flanges

- ASME SA182 F904L Long Weld Neck Flanges

- SS N08904 Long Welding Neck Flanges

- Stainless Steel 1.4539 Long Weld Neck Flange

- 904L SS Long Weld Neck Flange Exporter

- SS 904L Long Weld Neck Flanges Stockist

- 904L Stainless Steel Long Weld Neck Flanges Supplier

- SS 904L LWN Flanges

Lap Joint Flanges

- Stainless Steel 1.4539 Lap Joint Flange

- 904L SS Lapped Joint Flange Exporter

- SS 904L Lap Joint Flanges Stockist

- ASME SA182 SS 904L Lap Joint Flanges

- SS N08904 Lapped Joint Flanges

- 904L Stainless Steel Lap Joint Flanges Supplier

- SS 1.4539 Lap Joint Flanges

- 904L SS Lapped Joint Flanges

- 904L Stainless Steel LJ Flanges

- ASTM A182 F904L Lap Joint Flanges

Threaded Flanges

- Stainless Steel 1.4539 Threaded Flange

- 904L SS Screwed Flange Exporter

- 904L Stainless Steel Threaded Flanges Supplier

- SS 1.4539 Screwed Flanges

- SS 904L Threaded Flanges Stockist

- UNS N08904 Threaded Flanges

- SS 904L Screwed Flanges

- ASTM A182 F904L SS Threaded Flanges

- ASME SA182 SS 904L Threaded Flanges

- SS N08904 Screwed Flanges

ASTM A182 Stainless Steel 904L Flanges Chemical Composition

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Cu |

| SS 904L | 0.020 max | 2.00 max | 1.00 max | 0.040 max | 0.030 max | 19.00 – 23.00 | 4.00 – 5.00 max | 23.00 – 28.00 | 1.00 – 2.00 |

Stainless Steel 904L Flanges Mechanical Properties

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 7.95 g/cm3 | 1350 °C (2460 °F) | Psi – 71000 , MPa – 490 | Psi – 32000 , MPa – 220 | 35 % |

Other Types Stainless Steel 904L Flanges

- Stainless Steel 904L Loose Flange in Mumbai

- AISI 904L Plate Flanges Manufacturer

- UNS N08904 Flanges Supplier in India

- Stainless Steel 904L Nipo Flanges Exporters

- SS Grade 904L Spades Ring Spacers Flanges

- A182 Stainless Steel F904L SWRF Flanges

- SS 904L Class 300 Flat Flange in India

- Stainless Steel 1.4539 Flanges Pressure Rating

- ASME B16.5 SS 904L Long Weld Neck Flanges in India

- 904L Stainless Steel Tongue & Groove Flanges

- SS 1.4539 Screwed Flanges Manufacturer in India

- ASTM A182 F904L Expander Flanges at Best Price

- Stainless Steel 904L High Hub Blinds Flanges

- Stainless Steel 904L Orifice Flanges Manufacturer

- SS N08904 Reducing Flanges Supplier in India

- ASME SA182 SS 904L Expander Flanges Supplier

- 904L Stainless Steel Nipo Flanges

- 904L Stainless Steel Flanges Din Standard

- Stainless Steel 904L RTJ Flanges

- ANSI B16.5 Stainless Steel 904L Pipe Flange

- Grade F904L Stainless Steel SORF Flanges Exporter

- SS 904L Loose Flanges Supplier in Mumbai

Stainless Steel 904L Flanges Application Industries

Searches related to Stainless Steel 904L Flanges

We Export SS 904L Flanges to Following Destinations

Sri Lanka, Kuwait, Tunisia, Poland, Ecuador, Yemen, Venezuela, Turkey, Mexico, Angola, Serbia, Jordan, Indonesia, Iran, United States, Chile, Belarus, Egypt, Norway, Chile, Kenya, Bahrain, Netherlands, Bhutan, Trinidad & Tobago, Ghana, Morocco, Argentina, Azerbaijan, Mexico, Vietnam, Denmark, Hungary, Estonia, Malaysia, Poland, Czech Republic, Lithuania, Nigeria, Nigeria, Iraq, Oman, Qatar, Iran, South Korea, Thailand, Mongolia, Russia, Philippines, Ukraine, Bolivia, South Africa, Portugal, Italy, United Arab Emirates, Romania, Hong Kong, Switzerland, Australia, Costa Rica, Taiwan, Afghanistan, Bulgaria, Israel, Gabon, Austria, Lebanon, China, Singapore, New Zealand, Spain, Croatia, France, Brazil, Kazakhstan, Japan, Colombia, Pakistan, Saudi Arabia, Peru, Greece, Algeria, Libya, United Kingdom, Slovakia, Sweden, Bangladesh, Finland, Belgium, Canada.

Dallas, Caracas, Milan, Granada, Algiers, Jakarta, Ranchi, Pune, Madrid, Al Khobar, Navi Mumbai, Rio de Janeiro, Port-of-Spain, Hanoi, Riyadh, Lahore, Colombo, Bogota, Visakhapatnam, Toronto, Haryana, Coimbatore, Montreal, Kuala Lumpur, Kanpur, Thiruvananthapuram, Edmonton, Aberdeen, Mumbai, New York, Secunderabad, Muscat, Jeddah, Thane, Baroda, Ludhiana, Ankara, Calgary, Brisbane, Dubai, Jamshedpur, Manama, Sydney, Melbourne, Chandigarh, Dammam, Lagos, Surat, Kolkata, Nagpur, Al Jubail, Ahvaz, Kuwait City, Istanbul, Ahmedabad, Indore, Courbevoie, Ernakulam, Abu Dhabi, Gimhae-si, Noida, Vadodara, Busan, Chennai, Doha, Santiago, Tehran, Ulsan, Howrah, Vung Tau, Jaipur, Atyrau, Geoje-si, Bengaluru, Perth, Chiyoda, Bangkok, Sharjah, Pimpri-Chinchwad, Hyderabad, La Victoria, Los Angeles, Petaling Jaya, Cairo, New Delhi, Bhopal, Seoul, Houston, Faridabad, Rajkot, Ho Chi Minh City, Gurgaon, Nashik.