Stainless Steel 321/321H Flanges Supplier

ASTM A182 F321 FLANGES SUPPLIERS, STAINLESS STEEL 1.4878 FLANGES EXPORTER, SS 1.4541 FLANGE, AUSTENITIC STAINLESS STEEL 321H FLANGES, SS A182 F321H FLANGES, STAINLESS STEEL 321 FLANGES, STAINLESS STEEL 321H INDUSTRIAL FLANGES AT BEST PRICE, 321 STAINLESS STEEL FLANGES, UNS S32109 FLANGE, SS S32100 FLANGE, ASME SA182 321 STAINLESS STEEL FLANGES SUPPLIER IN INDIA.

- What is Stainless Steel 321 Flanges

- Standard Specification For Stainless Steel 321H Flanges

- Stainless Steel 321 Flanges Equivalent Grades

- Types of Stainless Steel 321H Flanges

- Stainless Steel 321 Flange Chemical Composition

- Mechanical Properties of SS 321 Flanges

- Other Types of 321H Stainless Steel Flanges Ready Stock

- Stainless Steel Grade 321 Flanges Applications

- Searches Related to Stainless Steel 321H Flanges

- Export Destinations for Stainless Steel 321 Flanges

Steel Sales Co is an establishment initiated in Mumbai with the practice of manufacturing and exporting Stainless Steel 321. We are associated with the huge industrial steel tycoons through whom we distribute these Stainless Steel 321H Flanges too. We are also occupied with being one of the well-known stockists of Stainless Steel 321 Flanges in the city. We are completely fine with customizing these Stainless Steel 321H Flanges for our patrons according to their specifications and requisitions.

The Stainless Steel 321 Flanges that we devise are embellished with elements that have superior chemical significance. When these elements are transformed into one chemical structure, they provide the SS 321 grade with an immense number of mechanical properties that differentiate the SS 321H Flanges from the other stainless steel grade flanges. In the chemical composition of the SS 321H grade, they have stabilized versions of the austenitic stainless steel alloys. These are stabilized by the element of titanium present in their elemental structure. These SS 321 Flanges possess a good amount of corrosion resistance caused in the most general aspects. Although these SS 321H Flanges exhibit an extremely great resistance against the intergranular corrosion that occurred due to the exposure the elevated temperatures during the process of chromium carbide precipitation, about 427OC – 816OC. Meanwhile, the SS 321 grade defends the oxidation even at 816OC. The Stainless Steel 304 alloy has the best and the most mechanical properties but the stress rupture and creep properties of the SS 321H alloy surpass the quality of the SS 304 alloy too. These Stainless Steel 321H Flanges function well and display a good amount of strength in cryogenic temperatures.

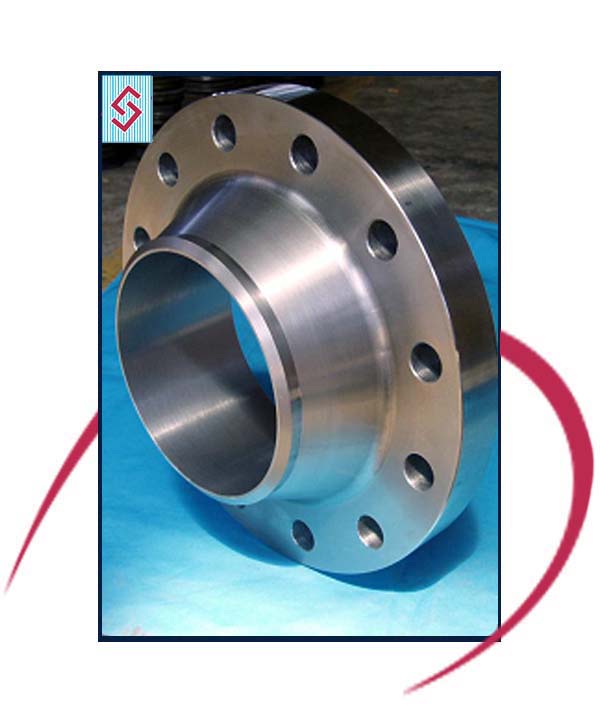

STAINLESS STEEL 321 FLAT FACE FLANGES, STAINLESS STEEL 321 LAP JOINT FLANGES, 321 STAINLESS STEEL RAISED FACE (RF) FLANGES, SS 321 BLIND FLANGE, 321 STAINLESS STEEL PIPE FLANGES EXPORTER, SS 321 SLIP ON FLANGES, SS 321H RING TYPE JOINT (RTJ) FLANGES, SS 321H THREADED / SCREWED FLANGES, SS 321H WELD NECK FLANGES, SS 321 FORGED FLANGES, SS 321 SORF FLANGES, STAINLESS STEEL 321 FLAT FACE (FF) FLANGES, STAINLESS STEEL 321H SOCKET WELD FLANGES, SS 321H SPECTACLE BLIND FLANGE STOCKIST, SS 321 BLRF FLANGE, STAINLESS STEEL 321 FLANGES MANUFACTURER IN MUMBAI.

The applications to which these Stainless Streel 321H Flanges are fabricated are quite vast and varied. But the basic areas and industries where these SS 321 Flanges can be applied are the expansion joints, refinery piping networks, underground water management, waste management systems, and many other chemical factories.

To assure our clients of our product quality of these Stainless Steel 321H Flanges, we carried out a few tests on the S 321 Flanges. The tests that were performed are the hardness test, flange test, positive material identification test, intergranular corrosion test, flattening test, macro test, micro test, and all the other minute chemical and mechanical testing.

Standard Specification

- Specifications

- Size

- Dimensions

- Standard

- Pressure Class / Rating

- Flange Connect Type/ Face Type

- Specialized manufacturer of

Stainless Steel 321 Flanges Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 321 | 1.4541 | S32100 | SUS 321 | – | – | – | X6CrNiTi18-10 |

| SS 321H | 1.4878 | S32109 | SUS 321H | – | – | – | X12CrNiTi18-9 |

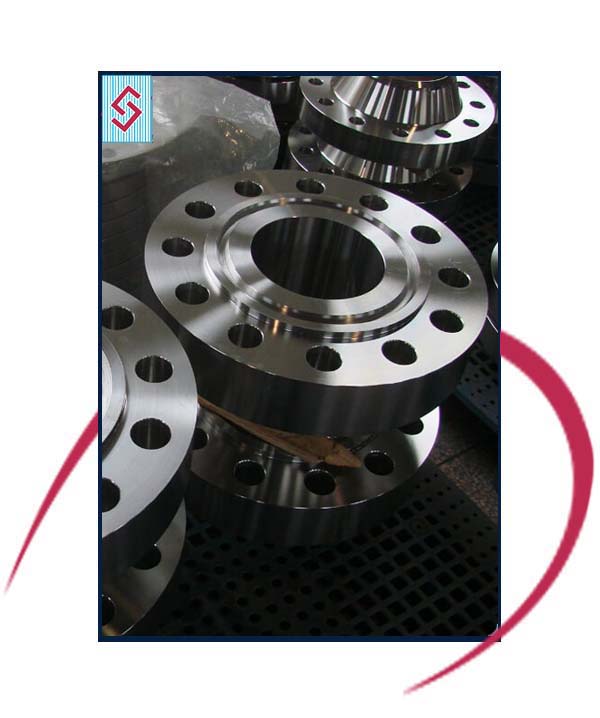

Types of Stainless Steel 321H Flanges

Slip On Flanges

- 321H Stainless Steel SOFF Flanges

- SS 321 SORTJ Flange

- SS 321 RFSO Flanges

- Stainless Steel S32109 Slip On Flanges

- ASME SA182 SS 321 SORF Flanges

- 321 Stainless Steel Slip On Flanges Supplier

- Stainless Steel 1.4541 Slip On Flange

- SS 321H Slip On Flanges Stockist

- ASTM A182 F321 Slip On Flanges Manufacturer

- SS S32100 Slip On Flanges

- 321H SS Slip On Flanges

- SS 1.4878 Slip On Flanges

- 321 SS Raised Face Slip on Flange Exporter

- Stainless Steel ASTM A182 F321H Slip On Flange

Weld Neck Flanges

- ASTM A182 321H Weld Neck Flanges

- SS 321H Weld Neck Flanges Stockist

- SS 1.4541 Weld Neck Flanges Manufacturer

- ASME SA182 SS 321 Weld Neck Flanges

- SS S32100 Weld Neck Flanges

- UNS S32109 Weld Neck Flanges

- Stainless Steel 321H WNFF Flange

- SS 321 RFWN Flange

- Stainless Steel 321 WNRTJ Flange

- ASME SA182 SS 321 Weld Neck Flanges

- SS 321 Welding Neck Flanges

- SS S32100 Weld Neck Flanges

- ASTM A182 F321 Weld Neck Flanges Supplier

- 321H SS Welding Neck Flange Exporter

- SS 321 WNRF Flanges

- Stainless Steel 1.4878 Weld Neck Flange

Socket Weld Flanges

- SS 321H SWFF Flange

- 321 SS RFSW Flanges

- ASTM A182 SS F321H Socket Weld Flanges

- ASME SA182 F321 Socket Weld Flanges

- UNS S32100 Socket Weld Flanges

- SS 1.4878 Socket Weld Flanges

- SS 1.4541 Socket Weld Flanges

- Stainless Steel 321H Socket Weld Flange

- SS 321 SWRTJ Flanges

- Stainless Steel 321H SWRF Flanges

- SS S32100 Socket Weld Flanges

- 321 Stainless Steel Socket Weld Flanges Supplier

- Stainless Steel S32109 Socket Weld Flange

- SS 321 Socket Weld Flanges Stockist

- 321 SS Socket Weld Flange Exporter

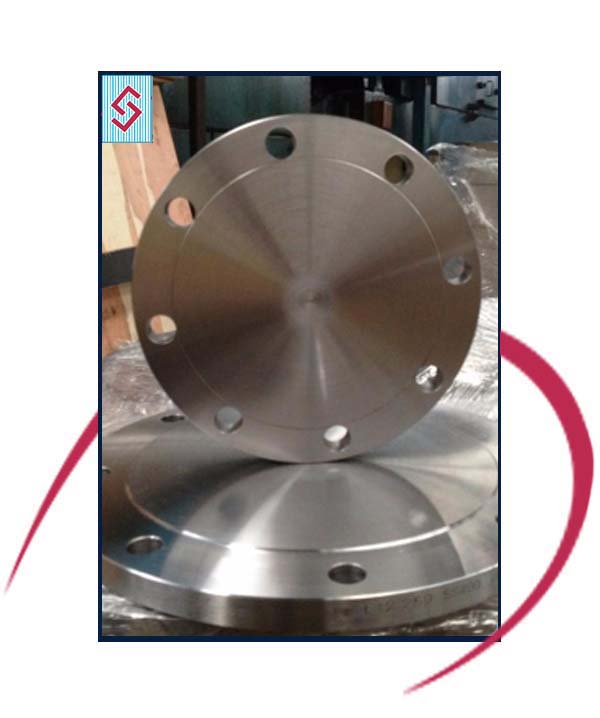

Blind Flanges

- SS 1.4878 Blind Flange

- SS 321 BLFF Flange

- SS 321H BLRF Flanges

- Stainless Steel 321 Blind Flange

- UNS S32109 Blind Flanges

- 321H Stainless Steel Blind Flanges Supplier

- Stainless Steel S32100 Blind Flanges Manufacturer

- SS 1.4541 Blind Flanges

- Stainless Steel 321 BLRTJ Flange

- Stainless Steel 321 RFBL Flanges

- ASTM A182 F321 Blind Flanges

- SS ASTM A182 F321H Blind Flanges Stockist

- 321 SS Raised Face Blind Flange Exporter

Ring Type Joint Flanges

- SS 1.4878 Ring Type Joint Flanges

- 321 SS Ring Type Joint Flange Exporter

- SS 321H RTJ Flanges Stockist

- ASTM A182 SS 321H Ring Type Joint Flanges

- UNS S32109 RTJ Flanges

- SS 321 RTJ Flanges

- Stainless Steel 321 Ring Joint Flanges

- ASME SA182 SS 321 Ring Type Joint Flanges

- SS S32100 RTJ Flanges

- 321H Stainless Steel Ring Type Joint Flanges Supplier

- SS 1.4541 Ring Type Joint Flanges

Spectacle Blind Flanges

- SS 1.4878 Spectacle Blind Flanges

- UNS S32109 Spectacle Blind Flanges

- ASTM A182 F321 Spectacle Blind Flanges

- Stainless Steel ASME SA182 F321H Spectacle Blind Flanges

- SS 1.4541 Spectacle Blind Flanges Manufacturers

- SS 321 Spectacle Blind Flanges Stockist

- SS S32100 Spectacle Blind Flanges

- 321 SS Spectacle Blind Flange

- 321H SS Spectacle Blind Flange Exporter

- SS ASME SA182 321H Spectacle Blind Flanges

- Stainless Steel 321H Spectacle Blind Flanges Supplier

Long Weld Neck Flanges

- ASME SA182 F321 Long Weld Neck Flanges

- 321 Stainless Steel Long Weld Neck Flanges

- UNS S32109 Long Weld Neck Flanges

- SS 321 LWN Flanges Supplier

- Stainless Steel 321H LWN Flange

- SS 321H Long Weld Neck Flange Exporter

- SS 321 Long Weld Neck Flanges Stockist

- SS 1.4541 Long Weld Neck Flanges

- Stainless Steel S32100 Long Welding Neck Flanges

- SS 1.4878 Long Welding Neck Flanges

- SS ASTM A182 F321H Long Weld Neck Flanges

Lap Joint Flanges

- SS S32100 Lapped Joint Flanges

- 321H Stainless Steel Lap Joint Flanges Supplier

- SS 1.4541 Lap Joint Flanges

- SS 321 LJ Flanges

- Stainless Steel 321H Lap Joint Flange

- 321H SS Lapped Joint Flange Exporter

- SS 321H LJ Flanges Stockist

- Stainless Steel 1.4878 Lapped Joint Flanges

- UNS S32109 Lap Joint Flanges

- Stainless Steel A182 F321H Lap Joint Flanges

- ASME SA182 SS F321 Lap Joint Flanges

Threaded Flanges

- UNS S32100 Threaded Flanges

- Stainless Steel 1.4541 Threaded Flanges

- SS 1.4878 Threaded Flanges

- UNS S32109 Threaded Flanges

- SS 321 Screwed Flanges

- Stainless Steel 321-321H Threaded / Screwed Flange

- SS 321H Screwed Flange Exporter

- SS ASME SA182 F321H Threaded Flanges

- ASTM A182 Stainless Steel F321 Threaded Flanges

- SS 321 Threaded Flanges Stockist

- 321H Stainless Steel Threaded Flanges Supplier

ASTM A182 Stainless Steel 321 Flanges Chemical Composition

| Grade | C | Mn | Si | P | S | Cr | N | Ni | Ti |

| SS 321 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 17.00 – 19.00 | 0.10 max | 9.00 – 12.00 | 5(C+N) – 0.70 max |

| SS 321H | 0.04 – 0.10 | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 17.00 – 19.00 | 0.10 max | 9.00 – 12.00 | 4(C+N) – 0.70 max |

Stainless Steel 321 Flanges Mechanical Properties

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1457 °C (2650 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

Other Types Stainless Steel 321H Flanges

- ASME SA182 SS 321 Expander Flanges Supplier

- 321H Stainless Steel Nipo Flanges

- Stainless Steel 321 RTJ Flanges

- 321 Stainless Steel Flanges Din Standard

- 321H SS SORF Flanges Exporter

- SS 321H Loose Flanges Supplier in Mumbai

- ASTM A182 F321 Expander Flanges at Best Price

- Stainless Steel 321 High Hub Blinds Flanges

- ANSI B16.5 Stainless Steel 321 Pipe Flange

- Stainless Steel 321 Orifice Flanges Manufacturer

- SS S32100 Reducing Flanges Supplier in India

- SS 1.4878 Screwed Flanges Manufacturer in India

- SS 321H Class 300 Flat Flange in India

- Stainless Steel 1.4541 Flanges Pressure Rating

- ASME B16.5 SS 321 Long Weld Neck Flanges in India

- 321 Stainless Steel Tongue & Groove Flanges

- Stainless Steel 321H Nipo Flanges Exporters

- AISI 321 Plate Flanges Manufacturer

- SS Grade 321H Spades Ring Spacers Flanges

- A182 Stainless Steel F321H SWRF Flanges

- Stainless Steel 321 Loose Flange Stockholder in Mumbai

- UNS S32100 / S32109 Flanges Supplier in India

Stainless Steel 321 Flanges Application Industries

Searches related to Stainless Steel 321H Flanges

We Export SS 321 Flanges to Following Destinations