Stainless Steel 316 Tube Plug (Port Ends) Supplier

SS 316 TUBE PLUG NPT THREAD, STAINLESS STEEL 316/316L TUBE PLUG (PORT ENDS) SUPPLIERS, 316L STAINLESS STEEL BOILER TUBE PLUG (PORT ENDS), STAINLESS STEEL 1.4401 TUBE PLUG, STAINLESS STEEL S31600 TUBE PLUGS, AUSTENITIC STAINLESS STEEL 316 TUBE PLUGS, 316 STAINLESS STEEL SINGLE BOILER TUBE PLUG EXPORTER, STAINLESS STEEL 1.4435 TUBE PLUG (PORT ENDS) SUPPLIER IN INDIA.

- What is Stainless Steel 316/316L Tube Plug

- Standard Specification For Stainless Steel 316/316L Tube Plug (Port Ends)

- Stainless Steel 316/316L Tube Plug Equivalent Grades

- Types of Stainless Steel 316/316L Tube Plugs

- Stainless Steel 316/316L Tube Plug Chemical Composition

- Mechanical Properties of SS 316/316L Tube Plug (Port Ends)

- Other Types of 316/316L Stainless Steel Tube Plugs Ready Stock

- Stainless Steel Grade 316/316L Tube Plug Applications

- Searches Related to Stainless Steel 316/316L Tube Plug (Port Ends)

- Export Destinations for Stainless Steel 316/316L Tube Plugs

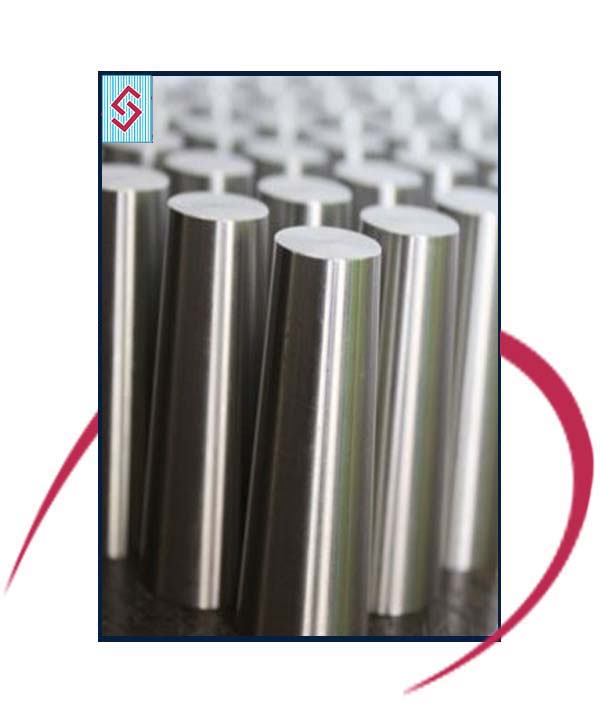

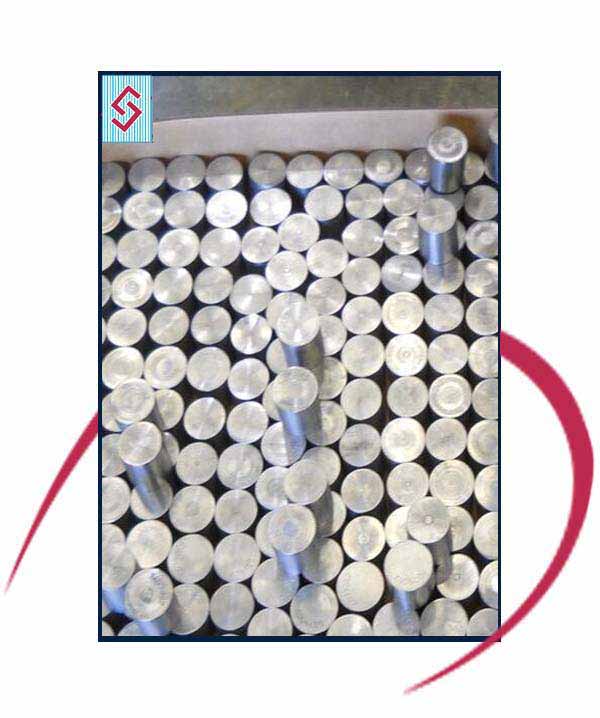

Steel Sales Co have been known for providing the products with the best quality, standardized specifications and quality products. Only the superior grades are only accessible with Steel Sales Co. We provide various sizes, grades, finishes and other dimensions of these Stainless Steel 316 tube plugs (portends) as per the requirements of various industries. We provide high-grade Stainless Steel products that are made with components like Chromium, nickel, carbon, iron and so on. Particularly, Stainless still 316 is an austenitic stainless steel alloy that exhibit qualities such as corrosion resistance, high strength. These qualities are possible due to high concentrations of chromium and nickel. This composotion is capable of resisting effects of harsh chemicals too.

Stainless Steel 316 tube plugs (portends) are tools that resemble injections. They are very affordable and are within the budget. They are structured with great care and observation. Stainless Steel 316 tube plugs (portends) are able to confront the struggles of corrosive materials around them. The effect of reducing and oxidizing factors have no significant impact on Stainless Steel 316 tube plugs (portends). Their sturdiness and toughness have made them accepted in wide industrial application range. Stainless Steel 316 tube plugs (portends) can combat various degrees of temperatures too. Steel Sales Co have appointed the best craftsmen to design and structure such plugs, which are an essential part of many devices. They not only assist functioning but also accelerate the rate of manufacturing.

SS 316L TAPERED TUBE PLUG (PORT ENDS) STOCKIST, SS 316 1/2" TUBE PLUGS, SS 316 ONE PIECE TUBE PLUGS, SS 316/316L HYDRAULIC TUBE PLUG (PORT ENDS), STAINLESS STEEL 316 BSP THREADS TUBE PLUG, STAINLESS STEEL 316 INDUSTRIAL COMPRESSION TUBE PLUGS AT BEST PRICE, SS 316 HEAT EXCHANGER TUBE PLUG FITTING, SS 316 TWO PIECE TUBE PLUG, SS 316 INSTRUMENTATION TUBE PLUG, STAINLESS STEEL 316 BOILER TUBE PLUG (PORT ENDS), SS 316 TORQ N’ SEAL MECHANICAL TUBE PLUG, SS 316 FERRULE TUBE PLUG, STAINLESS STEEL 316 TUBE PLUG MANUFACTURER IN MUMBAI.

Standard Specification

- Specifications

- Temperature

- Category

- Threads

- Size Range

- Pressure Rating

- Thread size

Stainless Steel 316/316L Tube Plug Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 316 | 1.4401 / 1.4436 | S31600 | SUS 316 | 316S31 / 316S33 | – | Z7CND17‐11‐02 | X5CrNiMo17-12-2 / X3CrNiMo17-13-3 |

| SS 316L | 1.4404 / 1.4435 | S31603 | SUS 316L | 316S11 / 316S13 | 03Ch17N14M3 / 03Ch17N14M2 | Z3CND17‐11‐02 / Z3CND18‐14‐03 | X2CrNiMo17-12-2 / X2CrNiMo18-14-3 |

Types of Stainless Steel 316/316L Tube Plug

Heat Exchanger Tube Plug

- SS S31600 Heat Exchanger Tube Plug (Port Ends)

- Stainless Steel 316/316L Heat Exchanger Tube Plug

- SS 316 Heat Exchanger Tube Plug

- SS 1.4404 Heat Exchanger Tube Plug (Port Ends) Stockist

- SS 1.4401 Heat Exchanger Tube Plugs

- S31603 SS Heat Exchanger Tube Plug (Port Ends) Exporter

- 316L Stainless Steel Heat Exchanger Tube Plugs Supplier

- SS 316 Heat Exchanger Tube Plug Manufacturer

Condenser Tube Plug

- SS S31600 Condenser Tube Plug (Port Ends)

- SS 316L Condenser Tube Plugs

- Stainless Steel 316 Condenser Tube Plug

- S31603 SS Condenser Tube Plugs Exporter

- SS 1.4436 Condenser Tube Plug (Port Ends)

- SS 1.4435 Condenser Tube Plug Manufacturer

- SS 316/316L Condenser Tube Plugs Stockist

- 316 Stainless Steel Condenser Tube Plug (Port Ends) Supplier

Boiler Tube Plug

- SS 316/316L Boiler Tube Plugs Stockist

- Stainless Steel S31603 Boiler Tube Plug (Port Ends)

- 316 Stainless Steel Boiler Tube Plug Supplier

- 1.4435 SS Boiler Tube Plugs Exporter

- SS 316L Boiler Tube Plug (Port Ends) Manufacturer

- SS 316 Boiler Tube Plug (Port Ends)

- SS 1.4401 Boiler Tube Plug (Port Ends)

- SS S31600 Boiler Tube Plugs

Stainless Steel 316/316L Tube Plug Chemical Composition

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Fe |

| SS 316 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 16.00 – 18.00 | 2.00 – 3.00 | 11.00 – 14.00 | 67.845 min |

| SS 316L | 0.035 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 16.00 – 18.00 | 2.00 – 3.00 | 10.00 – 14.00 | 68.89 min |

Stainless Steel 316/316L Tube Plug Mechanical Properties

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

Other Types Stainless Steel 316/316L Tube Plug (Port Ends)

- Stainless Steel Grade 316L Tube Plugs

- SS S31603 Instrumentation Tube Plug Dealer in India

- SS 316 Ferrule Tube Plug (Port Ends) in Mumbai

- SS Grade 316/316L Industrial Tube Plugs

- Stainless Steel 1.4401 Tube Plug (Port Ends)

- 1.4435 Stainless Steel Tube Plug Manufacturer

- SS 316 Tube Plug (Port Ends) Supplier in India

- 316 Stainless Steel Tube x NPT Thread Tube Plug (Port Ends)

- 316 Stainless Steel Tube Plug (Port Ends) Supplier

- SS 316 Tube Plugs Stockholder

- SS 316L Tube Plug (Port Ends) Stockist in Mumbai

- UNS S31600 Tube Plug (Port Ends) Exporters

- Stainless Steel 316 Tube x BSP Thread Tube Plug

- SS S31600 NPT Thread Tube Plug (Port Ends)

- SS 316/316L BSP Thread Tube Plugs

- SS 1.4436 Compression Tube Plugs Manufacturer

Stainless Steel 316/316L Tube Plug Application Industries

Searches related to Stainless Steel 316/316L Tube Plug (Port Ends)

We Export SS 316/316L Tube Plug to Following Destinations