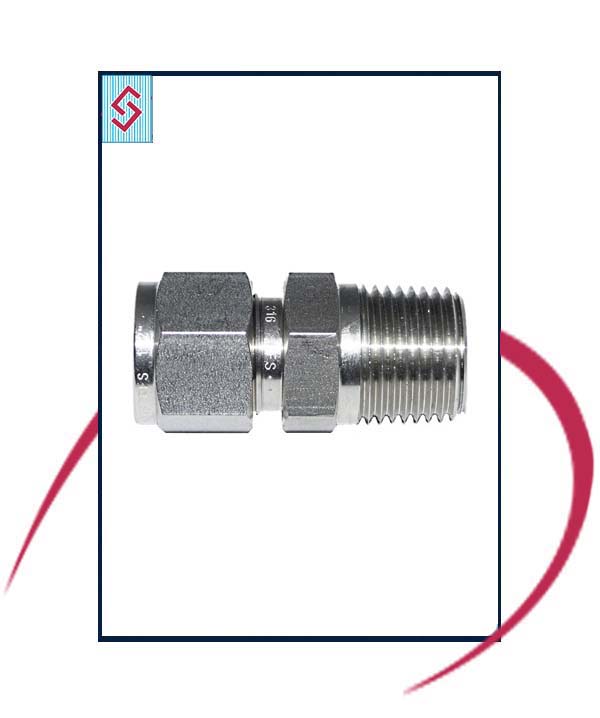

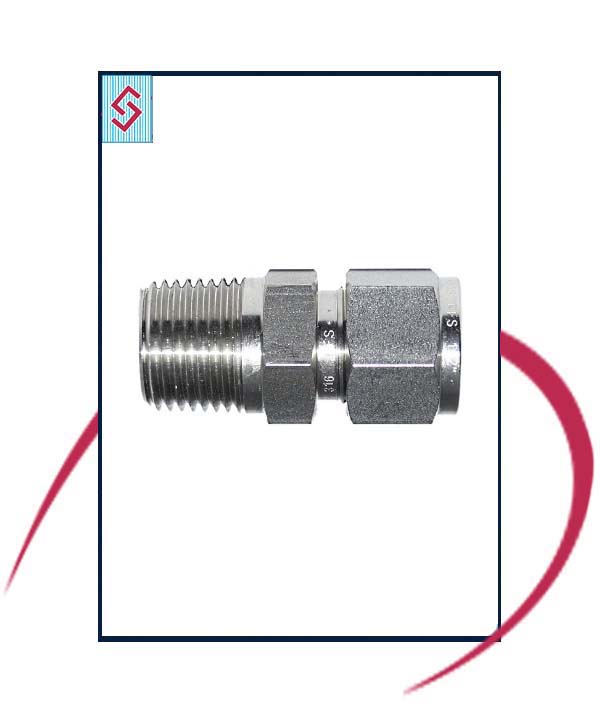

Stainless Steel 316 Male Connector NPT Supplier

STAINLESS STEEL 316 NPT MALE CONNECTOR SUPPLIERS, 316L STAINLESS STEEL FERRULE MALE CONNECTOR NPT, STAINLESS STEEL S31600 MALE CONNECTOR NPT, AUSTENITIC STAINLESS STEEL 316 MALE CONNECTOR NPT, SS 316/316L MALE CONNECTOR NPT THREAD, STAINLESS STEEL 1.4401 MALE CONNECTOR NPT, 316 STAINLESS STEEL SINGLE FERRULE MALE CONNECTOR NPT EXPORTER, STAINLESS STEEL 1.4404 MALE CONNECTOR NPT SUPPLIER IN INDIA.

- What is Stainless Steel 316/316L Male Connector NPT

- Standard Specification For Stainless Steel 316/316L Male Connector NPT

- Stainless Steel 316/316L Male Connector NPT Equivalent Grades

- Types of Stainless Steel 316/316L Male Connector NPT

- Stainless Steel 316/316L Male Connector NPT Chemical Composition

- Mechanical Properties of SS 316/316L Male Connector NPT

- Other Types of 316/316L Stainless Steel Male Connector NPT Ready Stock

- Stainless Steel Grade 316/316L Male Connector NPT Applications

- Searches Related to Stainless Steel 316/316L Male Connector NPT

- Export Destinations for Stainless Steel 316/316L Male Connector NPT

Steel Sales Co is a prominent manufacturer and merchant of Stainless Steel 316 Male Connector NPT. We used superior and premium quality grade crude materials for assembling standard quality Stainless Steel 316 Male Connector NPT. With the help of high qualitative materials, we offer the mechanical and physical properties, consistency, and working abilities with our Stainless Steel 316 Male Connector NPT. Stainless Steel alloy has the best of chemicals present in them, extending its unique qualities. Like a combination of nickel and chromium increases the oxidation fighting capacity of the steel and makes them more ductile.

The process of welding, casting can then be carried on them conveniently. Almost all stainless steel has two-third of the nickel content in them. Connectors of such fine steel make the joining very tight without chances of leakage.

SS 316 COMPRESSION NPT MALE CONNECTOR, STAINLESS STEEL 316L TUBE X NPT MALE CONNECTOR, STAINLESS STEEL 316/316L FERRULE NPT MALE CONNECTOR, SS 316 MALE CONNECTOR NPT STOCKIST, STAINLESS STEEL 316 INDUSTRIAL MALE CONNECTOR NPT AT BEST PRICE, SS 316 COMPRESSION NPT MALE CONNECTOR FITTING, SS 316 1/2" NPT MALE CONNECTOR, STAINLESS STEEL 316 DIN 17440 MALE CONNECTOR NPT, STAINLESS STEEL 316 MALE CONNECTOR NPT MANUFACTURER IN MUMBAI.

Male connectors can be attached to machine ports finely. They prefer the single-time configuration of these connectors to the tubes. Sterilization is done during manufacturing using ethylene oxide. The thread size is 1/8 inch, the appropriate length is ¾ inch, and the fitting width is 7/16 inch; these male connectors can be used for crevice services. Pressure areas of high range. Applications where process and control need high tube fittings. They offer torque-free seals to all types of tubular connections.

Standard Specification

- Specifications

- Temperature

- Category

- Threads

NPT

- Metric Size Range

- Inch Size Range

- Thread size

Stainless Steel 316/316L Male Connector NPT Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 316 | 1.4401 / 1.4436 | S31600 | SUS 316 | 316S31 / 316S33 | – | Z7CND17‐11‐02 | X5CrNiMo17-12-2 / X3CrNiMo17-13-3 |

| SS 316L | 1.4404 / 1.4435 | S31603 | SUS 316L | 316S11 / 316S13 | 03Ch17N14M3 / 03Ch17N14M2 | Z3CND17‐11‐02 / Z3CND18‐14‐03 | X2CrNiMo17-12-2 / X2CrNiMo18-14-3 |

Types of Stainless Steel 316/316L Male Connector NPT

Compression Male Connector NPT

- SS 316L Compression Male Connector NPT Stockist

- SS S31600 Compression NPT Male Connector

- 316 Stainless Steel Compression NPT Male Connector Supplier

- SS 1.4401 Compression Male Connector NPT

- SS S31603 Compression Male Connector NPT Manufacturer

- SS 1.4404 Compression Male Connector NPT Exporter

- Stainless Steel 316 Compression Male Connector NPT

- SS 316/316L Compression Male Connector NPT

Instrumentation Male Connector NPT

- Stainless Steel S31603 Instrumentation NPT Male Connector

- SS 1.4435 Instrumentation Male Connector NPT Stockist

- 316 SS Instrumentation Male Connector NPT Exporter

- SS 316/316L Instrumentation Male Connector NPT

- SS 1.4436 Instrumentation Male Connector NPT

- SS S31600 Instrumentation NPT Male Connector

- SS 316L Instrumentation Male Connector NPT Manufacturer

- 316 Stainless Steel Instrumentation Male Connector NPT Supplier

Ferrule Male Connector NPT

- SS S31600 Ferrule NPT Male Connector

- SS 316L Ferrule Male Connector NPT Stockist

- SS 1.4435 Ferrule Male Connector NPT

- SS S31603 Ferrule Male Connector NPT Manufacturer

- 316 Stainless Steel Ferrule NPT Male Connector Supplier

- SS 316/316L Ferrule Male Connector NPT

- SS 1.4401 Ferrule Male Connector NPT

- 316 SS Ferrule Male Connector NPT Exporter

Stainless Steel 316/316L Male Connector NPT Chemical Composition

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Fe | |

| SS 316 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 16.00 – 18.00 | 2.00 – 3.00 | 11.00 – 14.00 | 67.845 min | |

| SS 316L | 0.035 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 16.00 – 18.00 | 2.00 – 3.00 | 10.00 – 14.00 | – | 68.89 min |

Stainless Steel 316/316L Male Connector NPT Mechanical Properties

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

Other Types Stainless Steel 316/316L Male Connector NPT

- Stainless Steel Grade 316L NPT Male Connector

- UNS S31603 Tube x NPT Male Connector

- Stainless Steel 1.4436 NPT Male Connector

- SS 316 NPT Male Connector Supplier in India

- SS 1.4401 NPT Male Connector Dealer in India

- SS 1.4435 NPT Male Connector Manufacturer

- SS 316/316L NPT Male Connector in Mumbai

- SS Grade 316 Industrial Male Connector NPT

- 316L Stainless Steel Tube x NPT Male Connector Supplier

- Stainless Steel 316 Tube x NPT Male Connector

- SS 316 NPT Thread Male Connector

- SS S31600 NPT Thread Male Connector

- UNS S31600 NPT Male Connector Exporters

- SS 316 NPT Male Connector Stockist in Mumbai

- SS 1.4401 NPT Male Connector Manufacturer

- SS 316 Male Connector NPT Stockholder

Stainless Steel 316/316L Male Connector NPT Application Industries

Searches related to Stainless Steel 316/316L Male Connector NPT

We Export SS 316/316L Male Connector NPT to Following Destinations