Stainless Steel 316 Hose Nipple BSP Supplier

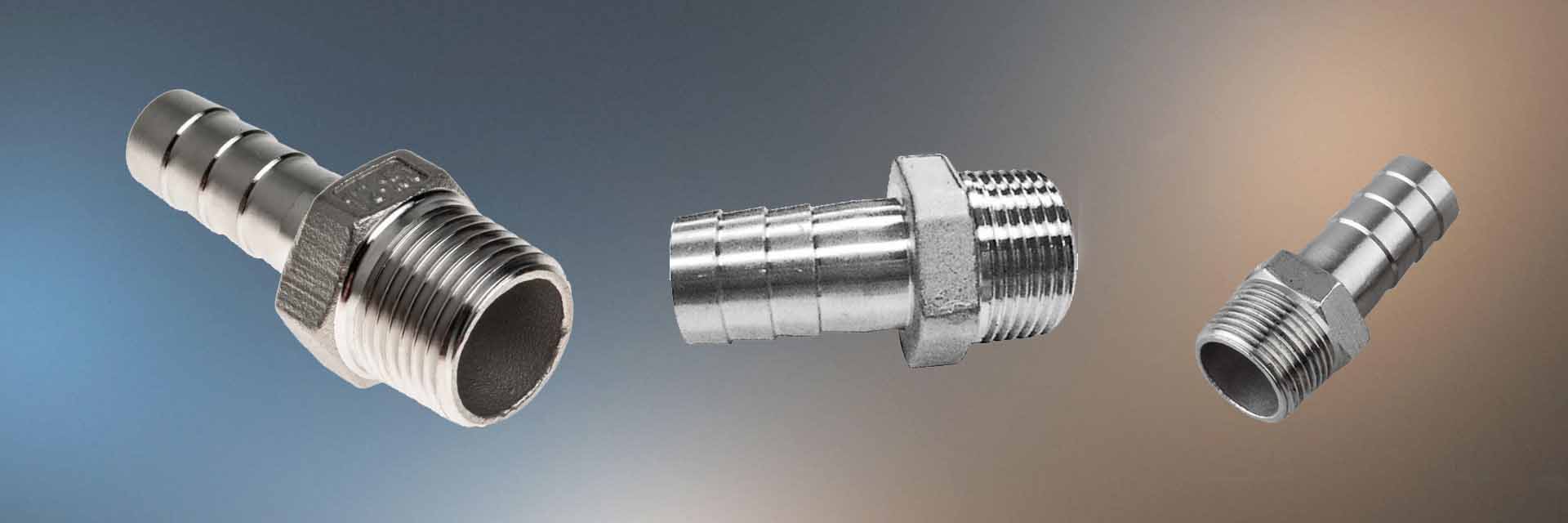

SS 316 Hose Nipple BSP Thread, 316 Stainless Steel Ferrule Hose Nipple BSP, Stainless Steel 316L BSP Hose Nipple Suppliers, Austenitic Stainless Steel 316/316L Hose Nipple BSP, Stainless Steel S31600 Hose Nipple BSP, 316 Stainless Steel Single Ferrule Hose Nipple BSP Exporter, Stainless Steel 1.4401 Hose Nipple BSP, Stainless Steel 316 Hose Nipple BSP Supplier in India

- What is Stainless Steel 316/316L Hose Nipple BSP

- Standard Specification For Stainless Steel 316/316L Hose Nipple BSP

- Stainless Steel 316/316L Hose Nipple BSP Equivalent Grades

- Types of Stainless Steel 316/316L Hose Nipple BSP

- Stainless Steel 316/316L Hose Nipple BSP Chemical Composition

- Mechanical Properties of SS 316/316L Hose Nipple BSP

- Other Types of 316/316L Stainless Steel Hose Nipple BSP Ready Stock

- Stainless Steel Grade 316/316L Hose Nipple BSP Applications

- Searches Related to Stainless Steel 316/316L Hose Nipple BSP

- Export Destinations for Stainless Steel 316/316L Hose Nipple BSP

Steel Sales Co is the main producer for Stainless Steel 316 Hose Nipple BSP, with an ISO affirmation. Austenitic Stainless Steel 316 Hose Nipple BSP are the principal choice for equipment that can persist through ruinous conditions. Stainless Steel 316 Hose Nipple BSP are wealthy in chromium and nickel, making them ideal for contradicting utilization. It similarly has amazing mechanical properties over the various assessments open on the lookout. While picking a Stainless Steel 316 Hose Nipple BSP that should bear dangerous conditions, austenitic hardened steel tubes are normally used. Having fabulous mechanical properties, the high proportions of nickel and chromium in austenitic stainless steels also present ascarce disintegration check. Besides, various Stainless Steel 316 Hose Nipple BSP are weldable and formable.

Stainless Steel 316/316L Hose Nipple BSP has a comparable material association as 304 Stainless steels. Regardless, despite high proportions of chromium and nickel, it also holds silicon, carbon, and manganese, with a giant piece including iron. Assessment Stainless Steel 316 Hose Nipple BSP has a denser engineered creation. It holds a ton of molybdenum of around 2-3% in weight diverged from the accompanying found in 304. Stainless Steel 316 Hose Nipple BSP does well in scented water, making it ideal for marine applications. Other customary usages of 316. Stainless Steel 316 Hose Nipple BSP are non-appealing, austenitic, and non-hardenable through heat treatment. The Stainless Steel 316 Hose Nipple BSP will go against disintegration, are extremely strong, and are conveniently outlined and made. Molybdenum further extends the operationconfirm of the material, making it ideal for logically acidic circumstances.

Stainless Steel 316 Industrial Hose Nipple BSP At Best Price, SS 316 1/2" BSP Hose Nipple, Stainless Steel 316 Ferrule BSP Hose Nipple, SS 316 Compression BSP Hose Nipple Fitting, Stainless Steel 316 Tube x BSP Hose Nipple, SS 316L Compression BSP Hose Nipple, Stainless Steel /316L Barbed Hose Nipple, SS 316 Hose Nipple BSP Stockist, Stainless Steel 316 Hose Nipple BSP Manufacturer in Mumbai.

With the help of these features and mechanical properties of Stainless Steel 316 Hose Nipple BSP, they have got huge demands from industries. They work reliably and flexibly with the all ranges of applications. the resistance to corrosion specifications and stains coupled with it being a low-maintenance metal, make Stainless Steel 316 Hose Nipple BSP an ideal choice for many applications.The addition of other elements and material compositions such as nickel, titanium, and molybdenum enhance Stainless Steel 316 Hose Nipple BSP’s corrosion-resistant properties even more. These are attractive features that are the reasons Hose Nipple BSP are used broadly.

Standard Specification

- Specifications

- Temperature

- Category

- Threads

- Size Range

- Thread size

Stainless Steel 316/316L Hose Nipple BSP Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 316 | 1.4401 / 1.4436 | S31600 | SUS 316 | 316S31 / 316S33 | – | Z7CND17‐11‐02 | X5CrNiMo17-12-2 / X3CrNiMo17-13-3 |

| SS 316L | 1.4404 / 1.4435 | S31603 | SUS 316L | 316S11 / 316S13 | 03Ch17N14M3 / 03Ch17N14M2 | Z3CND17‐11‐02 / Z3CND18‐14‐03 | X2CrNiMo17-12-2 / X2CrNiMo18-14-3 |

Types of Stainless Steel 316/316L Hose Nipple BSP

Compression Hose Nipple BSP

- SS 316L Compression Hose Nipple BSP

- S31603 Stainless Steel Compression BSP Hose Nipple Supplier

- SS 316 Compression Hose Nipple BSP Manufacturer

- 316 SS Compression Hose Nipple BSP Exporter

- SS 1.4401 / 1.4436 Compression Hose Nipple BSP

- SS S31600 Compression BSP Hose Nipple

- SS 316/316L Compression Hose Nipple BSP Stockist

- Stainless Steel 1.4404 Compression Hose Nipple BSP

Instrumentation Hose Nipple BSP

- SS 316L Instrumentation Hose Nipple BSP Stockist

- 316 Stainless Steel Instrumentation Hose Nipple BSP Supplier

- SS S31600 Instrumentation BSP Hose Nipple

- Stainless Steel 1.4435 Instrumentation BSP Hose Nipple

- SS S31603 Instrumentation Hose Nipple BSP Manufacturer

- SS 316/316L Instrumentation Hose Nipple BSP

- SS 1.4401 Instrumentation Hose Nipple BSP

- 316 SS Instrumentation Hose Nipple BSP Exporter

Ferrule Hose Nipple BSP

- 316L SS Ferrule Hose Nipple BSP Exporter

- SS S31600 Ferrule BSP Hose Nipple

- SS 1.4404 Ferrule Hose Nipple BSP Manufacturer

- Stainless Steel 316 Ferrule Hose Nipple BSP

- SS 316 Ferrule Hose Nipple BSP

- SS 1.4436 Ferrule Hose Nipple BSP

- SS 316/316L Ferrule Hose Nipple BSP Stockist

- S31603 Stainless Steel Ferrule BSP Hose Nipple Supplier

Stainless Steel 316/316L Hose Nipple BSP Chemical Composition

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Fe |

| SS 316 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 16.00 – 18.00 | 2.00 – 3.00 | 11.00 – 14.00 | 67.845 min |

| SS 316L | 0.035 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 16.00 – 18.00 | 2.00 – 3.00 | 10.00 – 14.00 | 68.89 min |

Stainless Steel 316/316L Hose Nipple BSP Mechanical Properties

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

Other Types Stainless Steel 316/316L Hose Nipple BSP

- SS Grade 316L Industrial Hose Nipple BSP

- SS 1.4404 / 1.4435 BSP Hose Nipple Dealer in India

- Stainless Steel Grade 316 BSP Hose Nipple

- Stainless Steel 1.4401 BSP Hose Nipple

- UNS S31600 BSP Thread Hose Nipple

- 316/316L Stainless Steel Tube x BSP Hose Nipple

- SS 316 BSP Hose Nipple Supplier in India

- 316 Stainless Steel BSP Hose Nipple Manufacturer

- SS 316L Hose Nipple BSP Stockholder

- SS 316 BSP Hose Nipple in Mumbai

- Stainless Steel 316 Tube x BSP Hose Nipple

- SS 316/316L BSP Hose Nipple Stockist in Mumbai

- SS 316 BSP Thread Hose Nipple

- 316 Stainless Steel Tube x BSP Hose Nipple Supplier

- SS 1.4436 BSP Hose Nipple Manufacturer

- UNS S31603 BSP Hose Nipple Exporters

Stainless Steel 316/316L Hose Nipple BSP Application Industries

Searches related to Stainless Steel 316/316L Hose Nipple BSP

We Export SS 316/316L Hose Nippler BSP to Following Destinations

Vietnam, Norway, Mongolia, Thailand, United Kingdom, Taiwan, Switzerland, Belarus, Iran, Argentina, Gabon, Peru, Nigeria, Ecuador, Canada, Hungary, Mexico, Sri Lanka, Ghana, Sweden, Finland, Kenya, Serbia, Angola, Portugal, Bolivia, Tunisia, Bulgaria, Ukraine, Morocco, Oman, Greece, Yemen, Netherlands, France, Croatia, Iraq, Italy, Indonesia, Venezuela, Azerbaijan, Mexico, Russia, Lebanon, United States, Iran, Philippines, Lithuania, Kuwait, Australia, South Africa, Algeria, Chile, Belgium, Kazakhstan, Bhutan, Israel, Jordan, Denmark, Trinidad & Tobago, Romania, Slovakia, Hong Kong, Turkey, Spain, Poland, New Zealand, Bahrain, Czech Republic, Singapore, Pakistan, Nigeria, Poland, United Arab Emirates, Estonia, Colombia, South Korea, Qatar, Austria, Costa Rica, Afghanistan, Bangladesh, Brazil, Libya, China, Egypt, Chile, Saudi Arabia, Japan, Malaysia.

Milan, Atyrau, Ho Chi Minh City, Rajkot, Ankara, New Delhi, Dammam, Doha, Lagos, Aberdeen, Ludhiana, Navi Mumbai, Geoje-si, Thiruvananthapuram, Nagpur, Caracas, Vadodara, Riyadh, Pimpri-Chinchwad, Faridabad, Petaling Jaya, Pune, Gimhae-si, Tehran, New York, Al Khobar, Melbourne, Thane, Sydney, La Victoria, Dallas, Nashik, Bengaluru, Hyderabad, Hanoi, Chiyoda, Indore, Sharjah, Madrid, Edmonton, Chennai, Jakarta, Bogota, Calgary, Manama, Ranchi, Santiago, Muscat, Los Angeles, Rio de Janeiro, Algiers, Colombo, Courbevoie, Noida, Bangkok, Dubai, Surat, Istanbul, Jaipur, Chandigarh, Houston, Brisbane, Kuwait City, Kuala Lumpur, Gurgaon, Granada, Visakhapatnam, Port-of-Spain, Kanpur, Seoul, Toronto, Vung Tau, Cairo, Perth, Secunderabad, Abu Dhabi, Ulsan, Jamshedpur, Ernakulam, Mumbai, Busan, Bhopal, Lahore, Jeddah, Coimbatore, Howrah, Al Jubail, Haryana, Baroda, Montreal, Kolkata, Ahvaz, Ahmedabad.