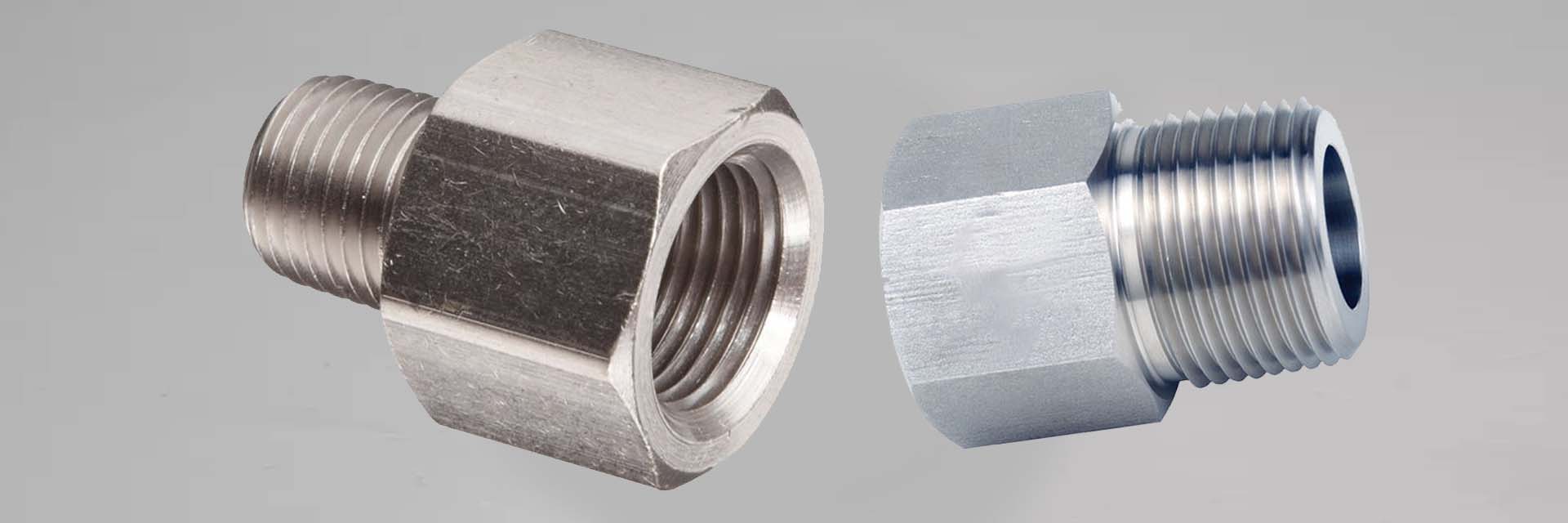

Stainless Steel 316 Female Adapter Supplier

Stainless Steel 316 female adapters are the most useful product in the market. Steel Sales Co is a successful organization due to their high-quality commodities and constructive attitude. Stainless Steel 316 female adapters have double ferrules one inside the other. These ferrules are very tough and sturdy. They are generally structured to being threaded in nature. The working medium that suits them best is water, gas, oil, chemicals, textiles and industries involving processing. The ferrules of such adapters are designed to meet the heavy duty applications. Their wall thickness is immense and other special features have made the work of machines easy and smooth. Many upgraded machines these days demand new tools and devices which must be of low maintenance feature, light-weighted, highly durable, stress-bearer and reasonable.

STAINLESS STEEL 316/316L FEMALE ADAPTER SUPPLIERS, SS 316 FEMALE ADAPTER NPT THREAD, 316 STAINLESS STEEL SINGLE FERRULE FEMALE ADAPTER EXPORTER, 316L STAINLESS STEEL FERRULE FEMALE ADAPTER, AUSTENITIC STAINLESS STEEL 1.4404 FEMALE ADAPTER, STAINLESS STEEL 1.4401 FEMALE ADAPTER, STAINLESS STEEL S31600 FEMALE ADAPTER, STAINLESS STEEL 316 FEMALE ADAPTER SUPPLIER IN INDIA.

- What is Stainless Steel 316/316L Female Adapter

- Standard Specification For Stainless Steel 316/316L Female Adapter

- Stainless Steel 316/316L Female Adapter Equivalent Grades

- Types of Stainless Steel 316/316L Female Adapter

- Stainless Steel 316/316L Female Adapter Chemical Composition

- Mechanical Properties of SS 316/316L Female Adapter

- Other Types of 316/316L Stainless Steel Female Adapter Ready Stock

- Stainless Steel Grade 316/316L Female Adapter Applications

- Searches Related to Stainless Steel 316/316L Female Adapter

- Export Destinations for Stainless Steel 316/316L Female Adapter

SS 316/316L FEMALE ADAPTER STOCKIST, STAINLESS STEEL 316 FERRULE FEMALE ADAPTER, STAINLESS STEEL 316 INDUSTRIAL FEMALE THREAD ADAPTER AT BEST PRICE, SS 316 COMPRESSION FEMALE ADAPTER FITTING, SS 316L HYDRAULIC FEMALE ADAPTER, STAINLESS STEEL 316 BSP THREADS FEMALE ADAPTER, SS 316 REINFORCED FEMALE ADAPTER, SS 316 1/2" FEMALE ADAPTER, SS 316 STYLUS FEMALE ADAPTER, STAINLESS STEEL 316 FEMALE ADAPTER MANUFACTURER IN MUMBAI.

Stainless Steel 316 female adapter are relatively less weighted as compared to other products, and their density is also perfect. Methods like forming can be conducted practically easily on them. Stainless Steel 316 female adapter are thermally conductive and electrical resistant, making them perfect for industrial use. These products are anodized or polished for the final finishings. Such Stainless Steel 316 female adapter are generally used for military gadget manufacturing, aerospace material making, etc.

Standard Specification

- Specifications

- Temperature

- Category

- Threads

- Size Range

- Thread size

Stainless Steel 316/316L Female Adapter Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 316 | 1.4401 / 1.4436 | S31600 | SUS 316 | 316S31 / 316S33 | – | Z7CND17‐11‐02 | X5CrNiMo17-12-2 / X3CrNiMo17-13-3 |

| SS 316L | 1.4404 / 1.4435 | S31603 | SUS 316L | 316S11 / 316S13 | 03Ch17N14M3 / 03Ch17N14M2 | Z3CND17‐11‐02 / Z3CND18‐14‐03 | X2CrNiMo17-12-2 / X2CrNiMo18-14-3 |

Types of Stainless Steel 316/316L Female Adapter

Compression Female Adapter

- SS 316/316L Compression Female Adapter

- Stainless Steel 1.4435 Compression Female Adapter

- 316 Stainless Steel Compression Female Adapter Supplier

- SS 1.4401 Compression Female Adapter

- SS 316 Compression Female Adapter Manufacturer

- SS S31603 Compression Female Adapter Stockist

- 316L SS Compression Female Adapter Exporter

- SS S31600 Compression Female Adapter

Instrumentation Female Adapter

- SS 316L Instrumentation Female Adapter

- Stainless Steel S31603 Instrumentation Female Adapter

- 316 SS Instrumentation Female Adapter Exporter

- SS S31600 Instrumentation Female Adapter

- SS 1.4401 Instrumentation Female Adapter

- SS 1.4435 Instrumentation Female Adapter Manufacturer

- 316/316L Stainless Steel Instrumentation Female Adapter Supplier

- SS 316 Instrumentation Female Adapter Stockist

Ferrule Female Adapter

- SS S31600 Ferrule Female Adapter

- SS 1.4436 Ferrule Female Adapter

- Stainless Steel 316 Ferrule Female Adapter

- SS 1.4404 Ferrule Female Adapter Manufacturer

- SS 316 Ferrule Female Adapter Stockist

- S31603 SS Ferrule Female Adapter Exporter

- 316 Stainless Steel Ferrule Female Adapter Supplier

- SS 316 Ferrule Female Adapter

Stainless Steel 316/316L Female Adapter Chemical Composition

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Fe |

| SS 316 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 16.00 – 18.00 | 2.00 – 3.00 | 11.00 – 14.00 | 67.845 min |

| SS 316L | 0.035 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 16.00 – 18.00 | 2.00 – 3.00 | 10.00 – 14.00 | 68.89 min |

Stainless Steel 316/316L Female Adapter Mechanical Properties

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

Other Types Stainless Steel 316/316L Female Adapter

- Stainless Steel 1.4435 Female Adapter

- Stainless Steel Grade 316 Female Adapter

- SS 316L Female Adapter Supplier in India

- 316 Stainless Steel Female Adapter Manufacturer

- SS 1.4436 Female Adapter Dealer in India

- 316 Stainless Steel Tube x NPT Thread Female Adapter

- UNS S31603 Female Adapter in Mumbai

- SS Grade 316/316L Industrial Female Adapter

- SS S31600 NPT Thread Female Adapter

- SS 316 Stylus Female Adapter Stockist in Mumbai

- SS 316/316L Female Thread Adapter Stockholder

- SS 316 BSP Thread Female Adapter

- SS 1.4401 Reinforced Female Adapter Manufacturer

- 316L Stainless Steel Female CMM Thread Stylus Adapter Supplier

- Stainless Steel 316 Tube x BSP Thread Female Adapter

- UNS S31600 Female Adapter Exporters

Stainless Steel 316/316L Female Adapter Application Industries

Searches related to Stainless Steel 316/316L Female Adapter

We Export SS 316/316L Female Adapter to Following Destinations

MATERIALS

PRODUCTS