Stainless Steel 310 / 310S / 310H Forged Fittings Supplier

Steel sales co is one of the leading manufacturer, supplier, distributor and stockiest of Stainless Steel 310 Forged Fittings Based in Mumbai, India. we use best available quality raw material to manufacture all our products using modern technology and advance machineries handled by our skilled and trained staff under observation of well experienced quality inspectors in order to provide best quality materials to our clients since years.

AUSTENITIC STAINLESS STEEL 310 FORGED FITTINGS, SS 310S FORGED FITTINGS, STAINLESS STEEL 310H FORGED FITTINGS, SS S31009 FORGED FITTINGS EXPORTER, 1.4845 STAINLESS STEEL FORGED FITTINGS, ASTM A182 F310 FORGED FITTINGS SUPPLIERS, STAINLESS STEEL S31000 FORGED FITTING, STAINLESS STEEL 1.4841 FORGED FITTING, STAINLESS STEEL 310S INDUSTRIAL FORGED FITTINGS AT BEST PRICE, STAINLESS STEEL S31008 FORGED FITTING, ASME SA182 STAINLESS STEEL 310 HIGH PRESSURE FORGED FITTINGS SUPPLIER IN INDIA.

- What is Stainless Steel 310 Forged Fittings

- Standard Specification For Stainless Steel 310S Forged Fittings

- Stainless Steel 310 Forged Fittings Equivalent Grades

- Types of Stainless Steel 310S Forged Fittings

- Stainless Steel 310H Socket Weld Fitting Chemical Composition

- Mechanical Properties of SS 310 Forged Fittings

- Other Types of 310S Stainless Steel Threaded Fittings Ready Stock

- Stainless Steel Grade 310H Forged Fittings Applications

- Searches Related to Stainless Steel 310 Screwed Fittings

- Export Destinations for Stainless Steel 310S Forged Fittings

Stainless steel 310S forged fittings consist of chromium, nickel and carbon components that makes stainless steel 310 resistant against corrosion as well as oxidation, it has great efficiency in moderate carburizing atmosphere. Stainless steel 310 forged fittings are not efficient for frequent liquid quenching as it suffers from thermal shock while processing. It has low magnetic permeability which makes it suitable for use in cryogenic applications. Its ductility enables it for usage in wide range like fluidized bed combustors, radiant tubes, tube hangers for petroleum refining, steam boilers, kilns, coal gasifier internal components, lead pots, refractory anchor bolts, combustion chambers, retorts, muffles, annealing covers, saggers, food processing equipment, cryogenic structures.

STAINLESS STEEL 310 COUPLING, STAINLESS STEEL 310 THREADED FITTINGS, SS S31009 FORGED PIPE FITTING, STAINLESS STEEL 310S THREADED FITTINGS, SS 310 FORGED ELBOW, STAINLESS STEEL F310H FORGED TEES, SS 310H SCREWED FITTINGS, ANSI B16.11 SS 310S FORGED FITTINGS, STAINLESS STEEL 310 SOCKET WELD FITTINGS, SS 310H FORGED CROSS, SS F310S FORGED UNION, SS 310S FORGED CAP, STAINLESS STEEL 310H BUSHING, 310S SS FORGED PLUGS, SS 310S THREADED NIPPLE STOCKIST, STAINLESS STEEL 310 FORGED FITTINGS MANUFACTURER IN MUMBAI.

Stainless steel 310H forged fittings is made up from low carbon version of stainless steel 310. Stainless steel 310s is less prone to sensitization, having chromium, nickel and carbon components. Both stainless steel 310 and stainless steel 310s are corrosion resistant and has ease of fabrication. It is slightly magnetic when in cold. having wide range application in muffles, saggers, food processing equipment, cryogenic structures, combustion chambers, retorts, kilns, coal gasifier internal components,steam boilers etc.

Standard Specification

- Specifications

- Size

- Dimensions

- Types

- Pressure Rating

Socket-weld End-3000/ 6000/ 9000lbs

- Thread

- Specialized Manufacturer

Stainless Steel 310 Screwed Fittings Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 310 | 1.4841 | S31000 | SUS 310 | 310S24 | 20Ch25N20S2 | – | X15CrNi25-20 |

| SS 310S | 1.4845 | S31008 | SUS 310S | 310S16 | 20Ch23N18 | – | X8CrNi25-21 |

| SS 310H | – | S31009 | – | – | – | – | – |

Types of Stainless Steel 310S Forged Fittings

Forged Elbows

- SS 1.4845 Forged Elbows

- UNS S31000 Forged Elbows

- ANSI B16.11 SS 310 Forged Elbows

- SS 1.4841 45 Deg Threaded Elbows

- 310H Stainless Steel Forged Elbows Supplier

- Stainless Steel 1.4841 Forged Elbow

- 310 SS 90 Degree Forged Elbow Exporter

- ASME SA182 F310H Forged Elbows

- Stainless Steel 310H NPT Screwed Elbow

- SS 310S Socket Weld Elbows Stockist

- ASTM A182 SS 310 BSPT Threaded Elbows Manufacturer

- SS S31009 90 Deg Forged Elbows

Forged Tee

- ASTM A182 F310 Forged Tee

- ANSI B16.11 SS 310S Forged Tee

- SS 310S Socket Weld Tee Stockist

- ASME SA182 SS 310H Forged Tee

- SS 1.4841 Equal Forged Tee

- Stainless Steel 1.4845 Forged Tee

- SS 1.4845 Forged Tee Manufacturer

- ASME SA182 SS 310 Forged Reducing Tees

- SS S31009 Screwed Tee

- 310 Stainless Steel BSPT Threaded Tee Supplier

- UNS S31008 Forged Tee

- 310S SS Unequal Forged Tee Exporter

- SS 310H NPT Threaded Forged Tee

Forged Cross

- ASTM A182 F310S Forged Cross

- SS 310 Socket Weld Cross Stockist

- ANSI B16.11 SS 310 Forged Cross

- 310 SS Unequal Forged Cross Exporter

- Stainless Steel 310S Forged Reducing Cross

- 310 Stainless Steel Forged Cross Supplier

- SS S31009 Forged Cross

- ASME SA182 SS 310H Forged Cross

- Stainless Steel S31008 Forged Cross

- UNS S31000 NPT Threaded Cross

- SS 1.4841 Equal Forged Cross

- SS 1.4845 BSPT Screwed Forged Cross

Coupling

- SS 310S Socket Weld Couplings Stockist

- UNS S31008 Couplings

- 310S Stainless Steel Couplings Supplier

- ASTM A182 F310 Couplings

- ANSI B16.11 SS 310S Forged Couplings

- SS 1.4841 Threaded Coupling

- 310 SS Full Coupling Exporter

- Stainless Steel 310 Half Coupling

- Stainless Steel 1.4841 BSPT Threaded Coupling

- SS S31009 Couplings Manufacturer

- SS 310H NPT Screwed Couplings

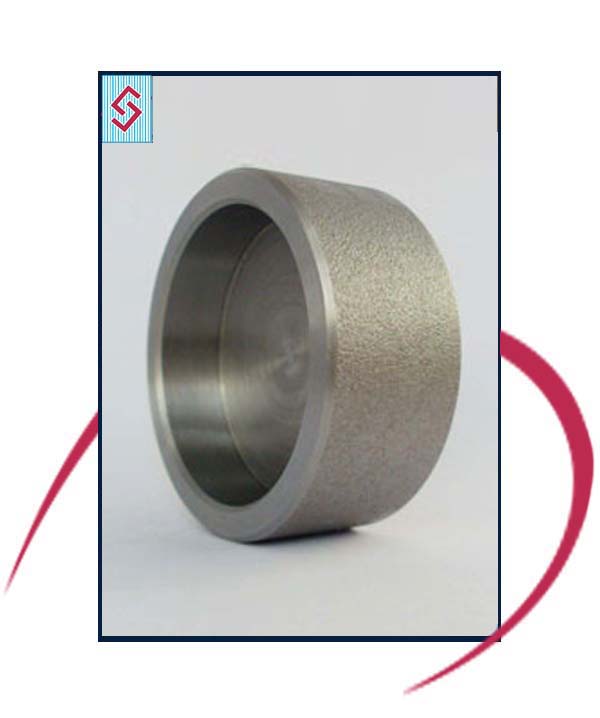

Forged Cap

- SS 1.4845 NPT Threaded Caps

- Stainless Steel 310H Forged Cap

- 310S SS Forged End Cap Exporter

- ASTM A182 F310S Forged Caps

- ANSI B16.11 SS 310H Forged Pipe End Cap

- SS S31009 Screwed Caps

- 310S Stainless Steel Forged Caps Supplier

- ASME SA182 SS 310S Forged End Caps

- UNS S31000 Forged Caps

- SS 310 Socket Weld End Pipe Caps Stockist

- SS 1.4841 BSPT Threaded Pipe Caps

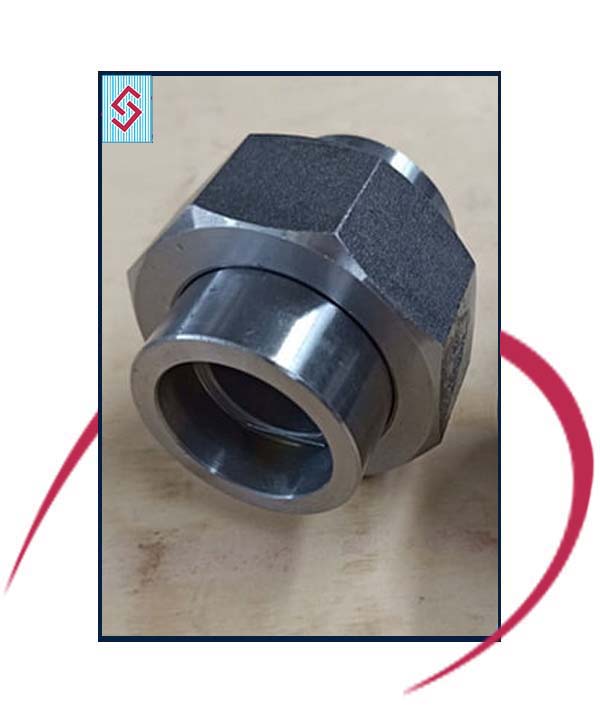

Union

- 310 SS Hex Head Union Exporter

- SS 310 Socket Weld Unions Stockist

- ASTM A182 F310S Unions

- ANSI B16.11 SS 310 Forged Union

- UNS S31008 Hex Unions

- SS 1.4841 BSPT Threaded Union

- SS S31009 Screwed Union

- SS 1.4841 NPT Threaded Unions

- 310S Stainless Steel Unions Supplier

- ASME SA182 SS 310S Unions

- SS 1.4845 Unions Manufacturer

Plug

- SS 310 Square Plugs Stockist

- UNS S31000 Round Head Plugs

- ASME SA182 SS 310S Plugs

- 310 SS Hex Head Plug Exporter

- SS S31009 Screwed Plug

- SS 1.4841 NPT Threaded Plugs

- 310S Stainless Steel Plugs Supplier

- Stainless Steel 310H Plug

- ASTM A182 F310S Plugs

- ANSI B16.11 SS 310H Forged Plug

- SS 1.4845 BSPT Threaded Plugs Manufacturer

Bushing

- UNS S31008 Bushings

- 310H Stainless Steel Hex Head Bushing

- ASME SA182 SS 310S Bushings

- 310 SS Bushing Exporter

- SS 310 BSPT Screwed Bushings Stockist

- SS S31009 Hex Head Bushing

- SS 1.4841 Threaded Bushings

- 310S Stainless Steel Bushings Supplier

- ASTM A182 F310S Bushings

- ANSI B16.11 SS 310 Forged Bushing

- SS 1.4845 NPT Threaded Bushings Manufacturer

Forged Nipple

- ANSI B16.11 SS 310 Forged Nipple

- ASTM A182 F310S Forged Nipples

- ASME SA182 SS 310S Forged Nipples

- 310 SS Socket Weld Nipple Exporter

- SS 1.4845 Forged Nipple

- SS S31009 Forged Nipple

- SS 310 Threaded Nipples Stockist

- UNS S31000 BSPT Threaded Swage Nipples

- SS 1.4841 NPT Screwed Nipples

- 310S Stainless Steel Forged Nipples Supplier

- SS 310H Forged Nipples Manufacturer

ASTM A182 Stainless Steel 310H Forged Fittings Chemical Composition

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N |

| SS 310 | 0.015 max | 2.0 max | 0.15 max | 0.020 max | 0.015 max | 24.00 – 26.00 | 0.10 max | 19.00 – 21.00 | 54.7 min |

| SS 310S | 0.08 max | 2.0 max | 1.00 max | 0.045 max | 0.030 max | 24.00 – 26.00 | 0.75 max | 19.00 – 21.00 | 53.095 min |

| SS 310H | 0.04 – 0.10 | 2.0 max | 1.00 max | 0.045 max | 0.030 max | 24.00 – 26.00 | – | 19.00 – 21.00 | 53.885 min |

Stainless Steel 310 Socket Weld Fittings Mechanical Properties

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 7.9 g/cm3 | 1402 °C (2555 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 40 % |

Other Types Stainless Steel 310S Forged Fittings

- SS 310 3000LB Threaded Fittings

- SS Grade F310 Screwed Plug

- SS 310 Unequal Cross Supplier in India

- SS 1.4845 Street Elbow Dealer in India

- UNS S31008 High Pressure Forged Fittings

- Stainless Steel 310 Forged Union

- UNS S31000 NPT Threaded Tee in Mumbai

- SS 310S 90 Degree Threaded Elbow Manufacturer

- SS 310S Forged Socket weld Fittings

- Stainless Steel 310H BSPP Screwed Coupling

- ASTM A182 F310S 45° Threaded Elbow

- SS S31008 Socket Weld Cross

- SS 310H High Pressure Forged Fittings

- SS 310H Half Coupling Stockholder

- 310 Stainless Steel Threaded Cross Supplier

- UNS S31009 Threaded Bushing Exporters

- SS 310S Forged Threaded Hex Nipple

- Stainless Steel 310H Forged Tee

- SS 310 BSPT Screwed Union Stockist in Mumbai

- SS 310 Swage Nipple Manufacturer

- SS 310S NPT Threaded Square Plug

- A182 Stainless Steel 310S Socket weld Pipe Cap

Stainless Steel 310H Threaded Fittings Application Industries

Searches related to Stainless Steel 310 Forged Fittings

We Export SS 310S Forged Fittings to Following Destinations

MATERIALS

PRODUCTS