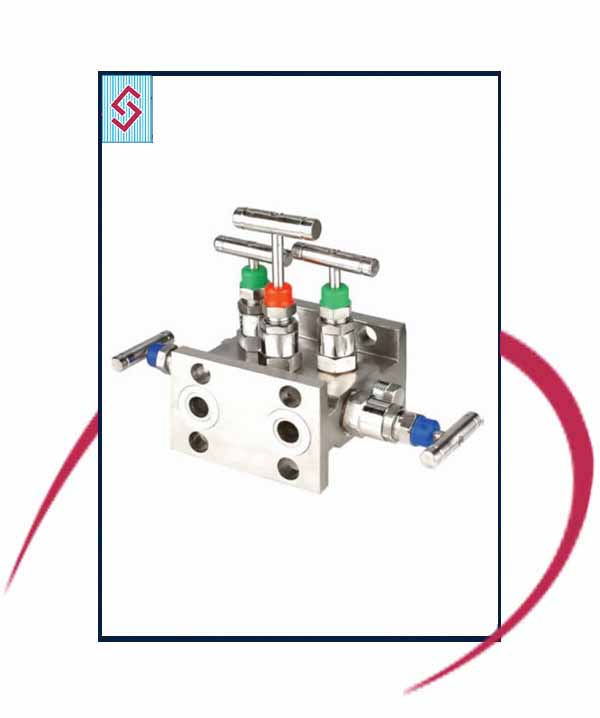

Stainless Steel 304 5 Way Manifold Valves Supplier

Steel Sales Co.is a prestigious Stainless Steel 304 5way Manifold Valves maker, which opposes polythionic corrosive pressure erosion breaking in hydrocarbon administration. Tempered Steel 304 5way Manifold Valves isn’t complex throughout heat treatment, yet minor parts can be hard work solidified. These Stainless Steel 304 5way Manifold Valves also performs better somewhat in vigorously oxidizing environments up to 816 Deg Celsius. Stainless Steel 304 5way Manifold Valves is utilized in most weakened natural acids at limited temperatures, in nitric arrangements, in unadulterated phosphoric corrosive at lower temperatures and up to 10 per cent of weakened performances at high temperatures. Stainless Steel 304 5way Manifold Valves is a columbium balanced out austenitic nickel-chromium item framed to offer a composite in the organization of an improved between granular-consumption opposition.

Stainless Steel 304L Industrial 5 Way Manifold Valves At Best Price, Stainless Steel 5 Way Manifold Valves Supplier, Stainless Steel 304/304L 5 Way Manifold Valves Suppliers, Austenitic Stainless Steel 1.4306 5-Valve Manifolds, SS 304 Five Way Manifold Valve, 304 Stainless Steel 5 Way Manifold Valves, Stainless Steel 1.4301 5 Way Valve Manifold, MSS SP-99 Stainless Steel 304 5 Way Manifold Valve, 304 Stainless Steel Five Valve Manifold Exporter, Stainless Steel S30400 5 Way Manifold Valve, Stainless Steel 304 5 Way Manifold Valves Supplier in India.

- What is Stainless Steel 304/304L 5 Way Manifold Valves

- Standard Specification For Stainless Steel 304/304L 5 Way Manifold Valves

- Stainless Steel 304/304L 5 Way Manifold Valves Equivalent Grades

- Types of Stainless Steel 304/304L 5 Way Manifold Valves

- Stainless Steel 304/304L 5 Way Manifold Valve Chemical Composition

- Mechanical Properties of SS 304/304L 5 Way Manifold Valves

- Other Types of 304/304L Stainless Steel 5 Way Manifold Valves Ready Stock

- Stainless Steel Grade 304/304L 5 Way Manifold Valves Applications

- Searches Related to Stainless Steel 304/304L 5 Way Manifold Valves

- Export Destinations for Stainless Steel 304/304L 5 Way Manifold Valves

SS 304/304L R Type 5 Way Manifold Valve, Stainless Steel 304 5 Way Remote Mount Manifold Valves, Stainless Steel 5 Way Manifold Valves Exporter, SS 304L 5 Way Direct Mount Manifold Valve, SS 304 5 Way Flange to Flange Manifold Valve, SS 304 H Type 5 Way Direct Mount Manifold Valves, SS 304 High-Pressure 5 Way Manifold Valves, Stainless Steel 304 5 Way Pipe to Flange Manifold Valves, Stainless Steel 304 5 Way Direct Mounting T-Type, Stainless Steel 304 5 Way Pipe to Pipe Manifold Valves, SS 304 Straight Type 5 Valve Manifold Stockist, Stainless Steel 304 5 Way Manifold Valves Manufacturer in Mumbai.

The 5 Way Manifold Valve comprises 2 square valves, one equalizer valve, and 2 test valves. This 5-way complex valve is the most well-known complex valve for differential pressing factor transmitters. Use Of Stainless-Steel Manifold Valves are Petrochemical, Ship Building, Water Treatment Plant, and so forth. We Supply 5-way complex valves with excellent tempered steel materials for its sturdiness and particular type in mechanical ventures. Steel Sales Co. is one of the leading Stainless Steel 304 5way Manifold Valves, Manufacturer in the country and abroad which sells 100% pure Stainless Steel 304 5way Manifold Valves of virgin raw material. We are providing the relevant documents, too, to the clients when delivering the materials.

Standard Specification

- Specifications

- Pressure Ratings

- Threads

- Mounting

“T” Type = Pipe to Flange,

“H” Type = Flange to Flange,

“RM” Type = Remote Mount,

“DM” Type = Direct Mount

- Size

- Temperature

- Stem packing

Stainless Steel 304/304L 5 Way Manifold Valves Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 304 | 1.4301 | S30400 | SUS 304 | 304S31 | 08Х18Н10 | Z7CN18‐09 | X5CrNi18-10 |

| SS 304L | 1.4306 / 1.4307 | S30403 | SUS 304L | 3304S11 | 03Х18Н11 | Z3CN18‐10 | X2CrNi18-9 / X2CrNi19-11 |

Types of Stainless Steel 304/304L 5 Way Manifold Valves

“R” Type 5 Way Manifold Valves

- ASME B16.34 SS 304 “R” Type 5 Way Manifold Valves

- SS 1.4301 R Type 5 Way Manifold Valves

- 304/304L Stainless Steel R-Type 5 Way Manifold Valves Supplier

- SS 1.4307 R Type 5 Way Manifold Valves Stockist

- ANSI B16.34 SS 304 R Type 5 Way Manifold Valves Manufacturer

- SS S30400 R Type 5 Way Manifold Valves

- 304 SS R Type 5 Way Manifold Valve Exporter

- Stainless Steel 304L R Type 5 Way Manifold Valve

“T” Type 5 Way Manifold Valves

- ASME B16.34 SS 304 “T” Type 5 Way Manifold Valves

- SS 1.4301 5 Valve Manifold-T Type

- 304L Stainless Steel T-Type 5 way Manifolds Supplier

- SS S30403 Tee Type 5 Valve Manifolds Stockist

- ANSI B16.34 SS 304 “T” Type 5 Way Manifold Valves Manufacturer

- SS S30400 “T” Type 5 Way Manifold Valves

- 304 SS “T” Type 5 Way Manifold Valve Exporter

- Stainless Steel 304/304L “T” Type 5 Way Manifold Valve

“H” Type 5 Way Manifold Valves

- ASME B16.34 SS 304 H-Type 5 way Manifold Valves

- SS 1.4301 H Type 5 Way Manifold Valves

- 304/304L Stainless Steel H-Type 5 Way Manifold Valves Supplier

- SS 304 “H” Type 5 Way Manifold Valves Stockist

- ANSI B16.34 SS 304 H-Type 5 Way Manifold Valves Manufacturer

- SS S30400 H Type 5 Way Manifold Valves

- 304L SS “H” Type 5 Way Manifold Valve Exporter

- Stainless Steel 1.4306 H-Type 5 Way Manifold Valve

Stainless Steel 304/304L 5 Way Manifold Valves Chemical Composition

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N |

| SS 304 | 0.08 max | 2 max | 0.75 max | 0.045 max | 0.030 max | 18 – 20 | – | 8 – 11 | – |

| SS 304L | 0.035 max | 2.0 max | 1.0 max | 0.045 max | 0.03 max | 18 – 20 | – | 8 – 13 | – |

Stainless Steel 304/304L 5 Way Manifold Valves Mechanical Properties

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

Other Types Stainless Steel 304/304L 5 Way Manifold Valves

- Stainless Steel 304/304L 5 Valve Manifold-H Type

- SS1.4306 5 Way Manifold Valve Manufacturer

- UNS S30400 5 Way Manifold Valves Exporters

- Stainless Steel 304 5 Valve Manifold-T Type

- ANSI B16.34 Stainless Steel 304 5 Way Manifold Valves

- SS 304 5 Way Manifold Valve Stockholder

- S30403 Stainless Steel 5 Way Manifold Valves Supplier

- Stainless Steel 304 “H” Type 5 Way Manifold Valves

- SS 304L 5 Way Manifold Valves Stockist in Mumbai

- SS S30400 “R” Type 5 Way Manifold Valves

- SS 304 “T” Type 5 Way Manifold Valve

- Stainless Steel 304 5 Valve Manifold-S Type

- Stainless Steel 5 Way Manifold Valves

- Stainless Steel 304 Flange to Flange 5 Way Manifold Valve

- Stainless Steel 1.4301 5 Way Manifold Valves

- ASME B16.34 SS 304/304L 5 Way Manifold Valve in Mumbai

- 304 Stainless Steel 5 Way Manifold Valve Manufacturer

- SS Grade 304 Industrial 5 Way Manifold Valves

- Stainless Steel 304 Pipe to Flange 5 Way Manifold Valves

- SS 304 5 Way Manifold Valves Supplier in India

- 304 Stainless Steel 5 Way Manifold Valves

- Stainless Steel Grade 304 5 Way Manifold Valve

- Stainless Steel 304 Pipe to Pipe 5 Way Manifold Valve

- SS 1.4301 5 Way Manifold Valve Dealer in India

- 304L SS 5 Valve Manifold Direct Mounting ‘T’ Type

Stainless Steel 304/304L 5 Way Manifold Valves Application Industries

Searches related to Stainless Steel 304/304L 5 Way Manifold Valves

We Export SS 304/304L 5 Way Manifold Valves to Following Destinations

MATERIALS

PRODUCTS