Stainless Steel 304 / 304L / 304H Forged Fittings Supplier

ASTM A182 F304 Forged Fittings Suppliers, SS 304L Forged Fittings, 304L Stainless Steel Forged Fittings, Stainless Steel S30400 Forged Fitting, Stainless Steel 304L Industrial Forged Fittings at Best Price, Austenitic Stainless Steel 304 Forged Fittings, Stainless Steel S30403 Forged Fitting, Stainless Steel 304H Forged Fittings, 304 Stainless Steel Forged Fittings Exporter, Stainless Steel 1.4301 Forged Fitting, ASME SA182 Stainless Steel 304 High Pressure Forged Fittings Supplier in India

- What is Stainless Steel 304 Forged Fittings

- Standard Specification For Stainless Steel 304L Forged Fittings

- Stainless Steel 304 Forged Fittings Equivalent Grades

- Types of Stainless Steel 304H Forged Fittings

- Stainless Steel 304L Socket Weld Fitting Chemical Composition

- Mechanical Properties of SS 304 Forged Fittings

- Other Types of 304L Stainless Steel Threaded Fittings Ready Stock

- Stainless Steel Grade 304H Forged Fittings Applications

- Searches Related to Stainless Steel 304L Screwed Fittings

- Export Destinations for Stainless Steel 304 Forged Fittings

Stainless steel 304L forged fittings are commonly used for connecting valves, pumps, pipes etc. which plays a great role in creating proper and efficient piping system. Threat fittings and Socket weld fittings are two main types of forged fittings. In thread fittings the pipe is screwed onto the fitting and in socket weld fitting it is connected to pipes by fillet welds. It is also considered as one of the dominant alloy in the market as it has great corrosion resistance due to its chromium, nickel and carbon components.it has great demand in market because of its corrosion resistant properties in different environments. Also its remarkable drawability plays a great role in shaping it in wide range of products. Its applicable in storage tanks, yeast plants, fermentation plants etc.

ANSI B16.11 SS 304L Forged Fittings, Stainless Steel 304 Socket weld Fittings, Stainless Steel 304L Threaded Fittings, Stainless Steel 304 Threaded Fittings, SS 304 Forged Elbow, Stainless Steel F304H Forged Tees, SS 304H Screwed Fittings, SS 304H Forged Cross, Stainless Steel 1.4306 Forged Fitting, Stainless Steel 304 Coupling, SS F304L Forged Union, SS 304L Forged Cap, SS 304L Threaded Nipple Stockist, Stainless Steel 304H Bushing, 304L SS Forged Plugs, Stainless Steel 304 Forged Fittings Manufacturer in Mumbai.

Stainless 304H forged fittings are products having chromium, carbon and nickel as components. Difference between stainless steel 304 and stainless steel 304L is slight but noticeable. While welding process stainless steel 304L’s lower carbon contents carbide participation is minimized while welding process. Stainless steel 304L have significant corrosion resistance in severely corrosive environments.

Standard Specification

- Specifications

- Size

- Dimensions

- Types

- Pressure Rating

Socket-weld End-3000/ 6000/ 9000lbs

- Thread

- Specialized Manufacturer

Stainless Steel 304 Screwed Fittings Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 304 | 1.4301 | S30400 | SUS 304 | 304S31 | 08Х18Н10 | Z7CN18‐09 | X5CrNi18-10 |

| SS 304L | 1.4306 / 1.4307 | S30403 | SUS 304L | 3304S11 | 03Х18Н11 | Z3CN18‐10 | X2CrNi18-9 / X2CrNi19-11 |

| SS 304H | 1.4948 | S30409 | SUS 304H | – | – | – | – |

Types of Stainless Steel 304H Forged Fittings

Forged Elbows

- ASME SA182 F304H Forged Elbows

- ANSI B16.11 SS 304 Forged Elbows

- SS 1.4948 Forged Elbows

- UNS S30403 Forged Elbows

- SS 1.4301 45 Deg Threaded Elbows

- 304H Stainless Steel Forged Elbows Supplier

- Stainless Steel 1.4307 Forged Elbow

- SS 304L Socket Weld Elbows Stockist

- ASTM A182 SS 304 BSPT Threaded Elbows Manufacturer

- SS S30409 90 Deg Forged Elbows

- 304 SS 90 Degree Forged Elbow Exporter

- Stainless Steel 304H NPT Screwed Elbow

Forged Tee

- ASTM A182 F304 Forged Tee

- ANSI B16.11 SS 304L Forged Tee

- SS 304L Socket Weld Tee Stockist

- ASME SA182 SS 304H Forged Tee

- SS 1.4301 Equal Forged Tee

- Stainless Steel 1.4307 Forged Tee

- SS 1.4948 Forged Tee Manufacturer

- ASME SA182 SS 304 Forged Reducing Tees

- UNS S30400 Forged Tee

- SS 304H NPT Threaded Forged Tee

- SS S30409 Screwed Tee

- 304 Stainless Steel BSPT Threaded Tee Supplier

- 304L SS Unequal Forged Tee Exporter

Forged Cross

- ASTM A182 F304L Forged Cross

- ANSI B16.11 SS 304 Forged Cross

- SS S30409 Forged Cross

- ASME SA182 SS 304L Forged Cross

- UNS S30403 NPT Threaded Cross

- SS 1.4301 Equal Forged Cross

- SS 1.4948 BSPT Screwed Forged Cross

- 304 Stainless Steel Forged Cross Supplier

- Stainless Steel 1.4306 Forged Cross

- SS 304 Socket Weld Cross Stockist

- 304 SS Unequal Forged Cross Exporter

- Stainless Steel 304L Forged Reducing Cross

Coupling

- ASTM A182 F304 Couplings

- ANSI B16.11 SS 304H Forged Couplings

- SS 304L Socket Weld Couplings Stockist

- UNS S30403 Couplings

- 304L Stainless Steel Couplings Supplier

- Stainless Steel 1.4306 BSPT Threaded Coupling

- SS S30409 Couplings Manufacturer

- SS 1.4948 NPT Screwed Couplings

- SS 1.4301 Threaded Coupling

- 304 SS Full Coupling Exporter

- Stainless Steel 304 Half Coupling

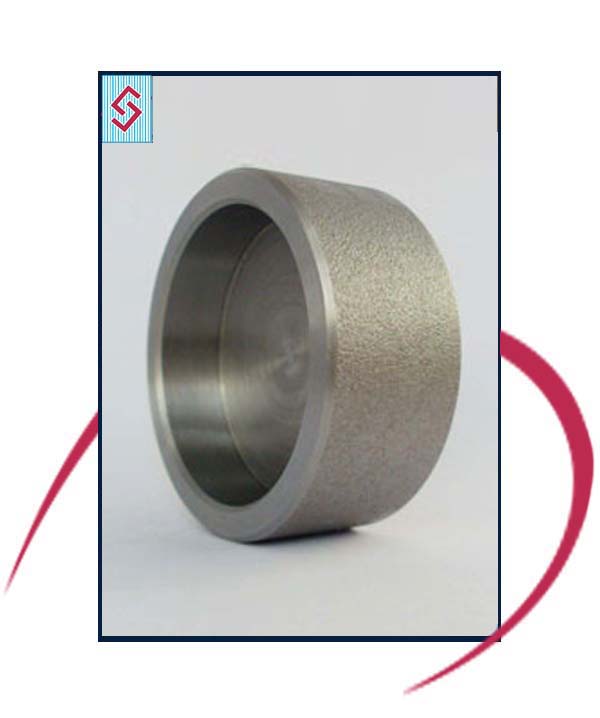

Forged Cap

- ASTM A182 F304L Forged Caps

- ANSI B16.11 SS 304 Forged Pipe End Cap

- ASME SA182 SS 304L Forged End Caps

- SS S30409 Screwed Caps

- 304L Stainless Steel Forged Caps Supplier

- SS 1.4948 NPT Threaded Caps

- Stainless Steel 1.4307 Forged Cap

- 304L SS Forged End Cap Exporter

- SS 304 Socket Weld End Pipe Caps Stockist

- SS 1.4301 BSPT Threaded Pipe Caps

- UNS S30403 Forged Caps

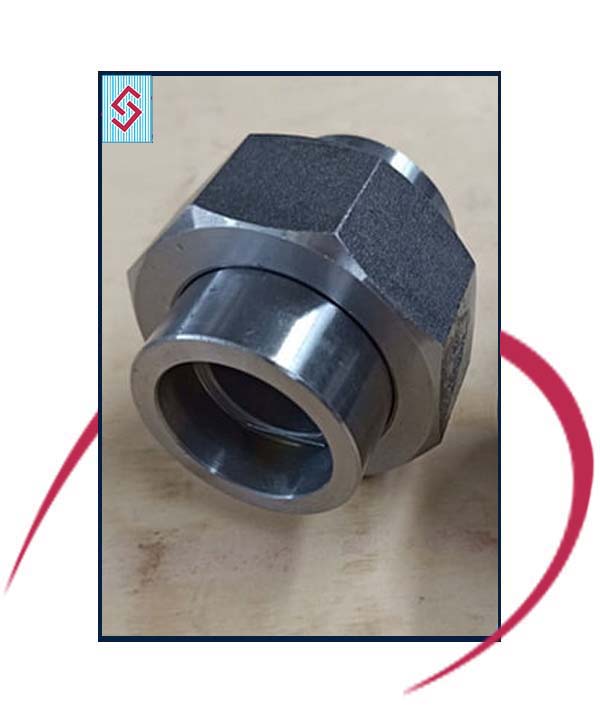

Union

- ASTM A182 F304L Unions

- ANSI B16.11 SS 304L Forged Union

- ASME SA182 SS 304L Unions

- 304 SS Hex Head Union Exporter

- SS S30409 Screwed Union

- SS 1.4301 NPT Threaded Unions

- 304L Stainless Steel Unions Supplier

- SS 1.4948 Unions Manufacturer

- SS 304 Socket Weld Unions Stockist

- UNS S30400 Hex Unions

- SS 1.4306 BSPT Threaded Union

Plug

- ASTM A182 F304L Plugs

- ANSI B16.11 SS 304 Forged Plug

- ASME SA182 SS 304L Plugs

- 304 SS Hex Head Plug Exporter

- SS S30409 Screwed Plug

- SS 1.4301 NPT Threaded Plugs

- 304L Stainless Steel Plugs Supplier

- SS 1.4948 BSPT Threaded Plugs Manufacturer

- SS 304 Square Plugs Stockist

- UNS S30403 Round Head Plugs

- SS 1.4307 Plug

Bushing

- ASTM A182 F304L Bushings

- ANSI B16.11 SS 304L Forged Bushing

- ASME SA182 SS 304L Bushings

- 304 SS Bushing Exporter

- SS S30409 Hex Head Bushing

- SS 1.4301 Threaded Bushings

- 304L Stainless Steel Bushings Supplier

- SS 1.4948 NPT Threaded Bushings Manufacturer

- SS 304 BSPT Screwed Bushings Stockist

- UNS S30400 Bushings

- SS 1.4307 Hex Head Bushing

Forged Nipple

- ASTM A182 F304L Forged Nipples

- ANSI B16.11 SS 304H Forged Nipple

- ASME SA182 SS 304L Forged Nipples

- 304 SS Socket Weld Nipple Exporter

- SS S30409 Forged Nipple

- SS 1.4301 NPT Screwed Nipples

- 304L Stainless Steel Forged Nipples Supplier

- SS 1.4948 Forged Nipples Manufacturer

- SS 304 Threaded Nipples Stockist

- UNS S30403 BSPT Threaded Swage Nipples

- SS 1.4306 Forged Nipple

ASTM A182 Stainless Steel 304L Forged Fittings Chemical Composition

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N |

| SS 304 | 0.08 max | 2 max | 0.75 max | 0.045 max | 0.030 max | 18 – 20 | – | 8 – 11 | – |

| SS 304L | 0.035 max | 2.0 max | 1.0 max | 0.045 max | 0.03 max | 18 – 20 | – | 8 – 13 | – |

| SS 304H | 0.10 max | 2.0 max | 0.75 max | 0.045 max | 0.03 max | 18 – 20 | – | 8 – 10.5 | – |

Stainless Steel 304 Socket Weld Fittings Mechanical Properties

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

Other Types Stainless Steel 304L Forged Fittings

- SS 304 3000LB Threaded Fittings

- SS Grade F304 Screwed Plug

- UNS S30400 NPT Threaded Tee in Mumbai

- SS 304L 90 Degree Threaded Elbow Manufacturer

- Stainless Steel 304 Forged Union

- SS 304L Forged Socket weld Fittings

- SS 304 Unequal Cross Supplier in India

- UNS S30403 High Pressure Forged Fittings

- ASTM A182 F304L 45° Threaded Elbow

- Stainless Steel 304H BSPP Screwed Coupling

- SS 1.4948 Street Elbow Dealer in India

- SS 304L Forged Threaded Hex Nipple

- SS 304 Swage Nipple Manufacturer

- UNS S30409 Threaded Bushing Exporters

- SS 304L NPT Threaded Square Plug

- A182 Stainless Steel 304L Socket weld Pipe Cap

- SS 304H Half Coupling Stockholder

- 304 Stainless Steel Threaded Cross Supplier

- Stainless Steel 304H Forged Tee

- SS 304 BSPT Screwed Union Stockist in Mumbai

- SS S30403 Socket Weld Cross

- SS 304H High Pressure Forged Fittings

Stainless Steel 304H Threaded Fittings Application Industries

Searches related to Stainless Steel 304L Forged Fittings

We Export SS 304 Forged Fittings to Following Destinations

MATERIALS

PRODUCTS