Slip-On Flanges Supplier

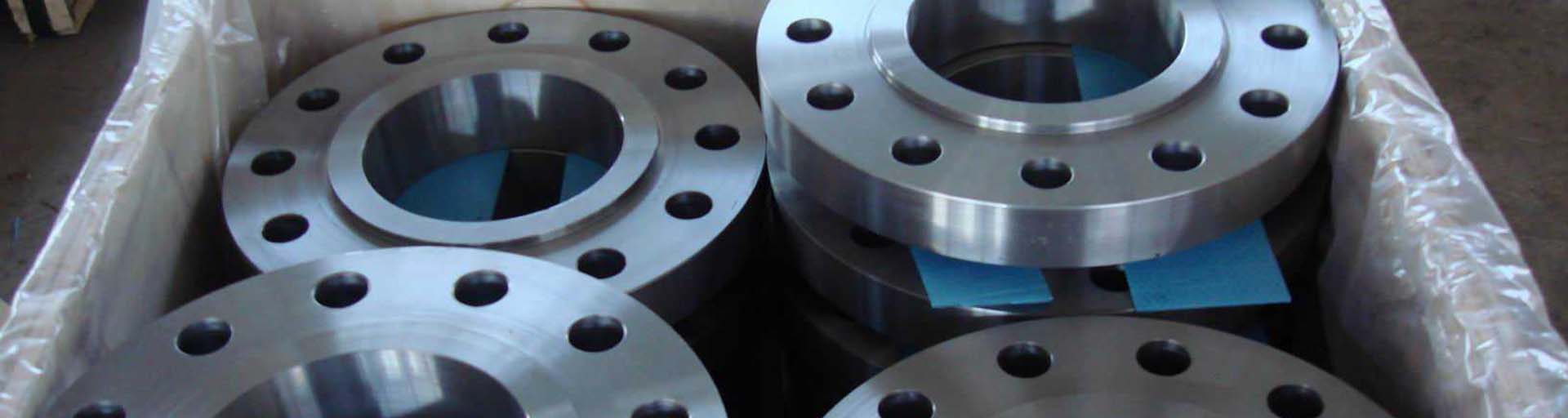

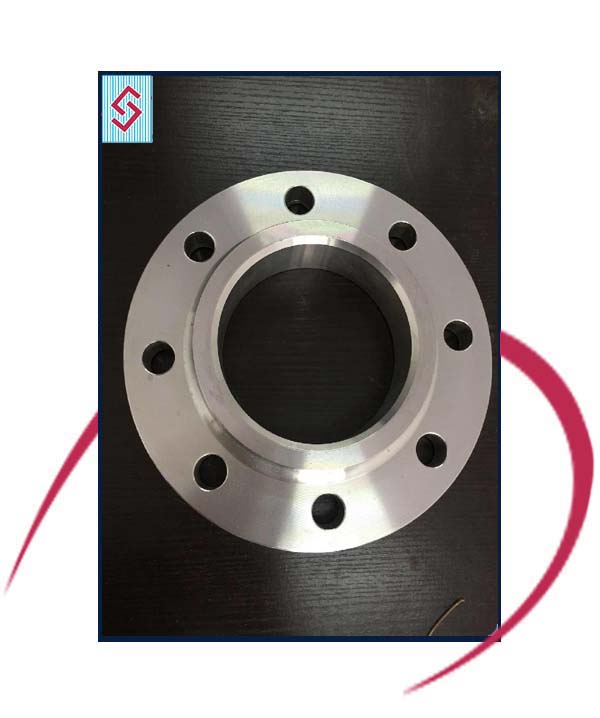

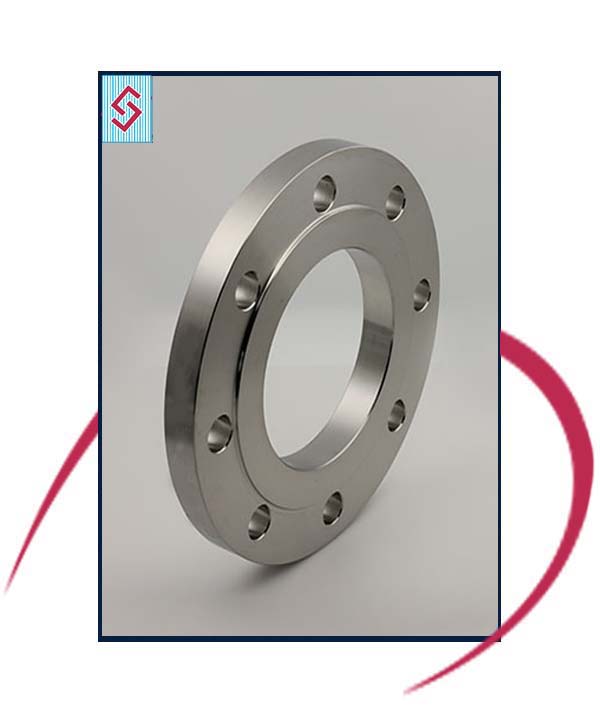

Slip on Flanges slip over the pipe, which is why they are called slip-on flanges. These flanges are made with an inside diameter that is greater than the outside diameter of the pipe. The tube is connected to these flanges by a fillet weld at the top and bottom of the flange. With a rising or smooth face, slip-on flanges are utilized. Carbon steel slip-on pipe flanges, stainless steel slip-on pipe flanges, and alloy steel slip-on pipe flanges are examples of these flanges. These flanges are leak-proof, reduced maintenance, and can swiftly maintain position even at boiling temperatures. These flanges are widely employed in a variety of sectors due to their outstanding characteristics.

ASME B16.5 Slip On Flange, High Quality Slip On Flanges, Slip On Flanges Suppliers, Flat Faced Slip On Flange, Industrial Slip On Flanges at Best Price, Austenitic Stainless Steel Slip On Flanges, Raised Face Slip On Flanges, SOFF Flanges, SO Flanges, ANSI B16.48 Slip-On Flanges Exporter, SORTJ Flanges, MSS SP-44 Slip on Flanges, Slip On Flanges Supplier in India

Steel Sales Co provides these Slip-on Flanges to esteemed customers in a variety of variants. Having been in this field for many years, we intend to understand the customer’s requirements and deliver these flanges in standard as well as custom dimensions. The thick walls of these Flanges allow them to work smoothly and without inconsistencies in any gaseous or oxidizing environment. We always make raw materials available only to our trusted sources.

ANSI B16.47 Series A & B Slip On Flanges, Super Duplex Steel Slip On Flanges, Inconel Slip-On Flanges, Alloy Steel Slip On Flange, Incoloy Slip On Flanges, Stainless Steel Slip On Flange, Carbon Steel Slip On Flanges, Duplex Steel Slip On Flange, Nickel Alloy Slip On Flange, Hastelloy Slip On Flanges, Monel Slip On Flanges, Titanium Slip On Flange, Slip On Flanges Manufacturer in Mumbai.

Even in extreme conditions, the Monel Alloy Slip-on Flanges are capable of performing. We have a limited supply of these flanges on hand in our highly secure warehouse for emergency use. Our Nickel Slip flanges are available to our valued customers at a competitive price when compared to other industries in the market.

Carbon Steel Flanges are finished, they are subjected to a series of rigorous tests to ensure that they meet all of their specifications. We also performed third-party tests at the request of clients to demonstrate the ability of Slip-on Flanges to survive any specified situation. At Steel Sales Co, our experienced engineers work around the clock to meet the needs of our customers. They also monitor the production process to ensure that no damage occurs during the manufacturing process.

Standard Specification

- Size

1/2″ (15 NB) to 48″ (1200NB) DN10~DN5000

- Dimensions

ANSI/ ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc.

- Standard

ANSI Flanges, AWWA Flanges, ASME Flanges, BS 10 Table D Flanges, Table E Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flanges.

- Pressure Class / Rating

Class 150 LBS, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc.

- Flange Connect Type/ Face Type

Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF) etc.

Types of Slip On Flanges

- ASME SA182 Slip On Flanges

- Stainless Steel 304 Slip On Flanges

- Stainless Steel SORTJ Flanges

- SS SO Flanges

- Stainless Steel Flat Face Slip On Flanges

- SS Slip On Flange Supplier

- Duplex Steel Slip-On Flanges

- Super Duplex Steel SOFF Stockist

- SS Slip On Flange Manufacturer

- 254 SMO Raised Face Slip On Flange

- ANSI B16.5 SS Slip On Flange Exporter

- ASME SA105 CS Slip On Flanges

- Carbon Steel IS 2062 Slip On Flanges

- Carbon Steel Ring Type Joint Slip On Flanges

- CS SO Flanges

- Alloy Steel Flat Face Slip On Flanges

- Chrome Moly SOFF Supplier

- A36 CS Slip On Flanges

- Alloy Steel F5 Slip On Flange Stockist

- ASTM A694 F42 SOFF Manufacturer

- Low Temperature Carbon steel Slip On Flange

- ANSI B16.5 CS Slip On Flange Exporter

- ASME SB564 High Nickel Alloy Slip On Flanges

- Nickel Alloy 200 Slip On Flanges

- Monel Ring Type Joint Slip On Flanges

- Inconel SO Flanges

- Incoloy Flat Face Slip On Flanges

- Hastelloy Slip On Flange Supplier

- Titanium Slip-On Flanges

- Alloy 20 SOFF Stockist

- Tantalum SOFF Manufacturer

- High Nickel Alloy Slip On Flange

- ANSI B16.5 Alloy Slip On Flange Exporter

Other Types Slip On Flanges

- ANSI B16.48 Slip On Flange Distributors

- BS4504 Slip On Flanges Supplier in India

- 2500 LBS Slip On Flange Stock

- High Quality Slip On Flanges

- Monel 400 Slip On Flanges Manufacturer

- 600 LBS Slip On Flanges

- High Nickel Alloy Slip-On Flanges

- Suppliers of SS Slip On Flanges

- ANSI B16.5 200 Nickel Alloy Slip On Flange

- ANSI B16.47 Slip On Flanges in Mumbai

- Carbon Steel Slip On Flange

- Slip On Flange Dimensions

- ASME B16.5 Slip On Flanges Stockholder

- 900 LBS Slip On Flanges Exporter

- Low Temperature Carbon steel Slip On Flanges

- 1500 LBS Slip On Flanges Stockist in Mumbai

- Steel Slip On Flanges Dealer in India

- ASTM A182 F304 Slip On Flange

- SS PN40 Slip On Flange Manufacturer

- PN16 Slip On Flanges Exporters

Slip On Flanges Application Industries

Searches Related to Slip On Flanges

We Export Slip On Flanges to Following Destinations

PRODUCTS

MATERIALS