Short Stub Ends Supplier

Seamless Long Stub End, Industrial Long Stub Ends at Best Price, Austenitic Stainless Steel Long Stub Ends, Butt weld Long Stub Ends Exporter, ASME B16.9 Long Stub End, High Quality Long Stub Ends, Welded Long Stub Ends, Buttweld Long Stub Ends, Long Stub Ends Suppliers, Long Stub Ends Supplier in India

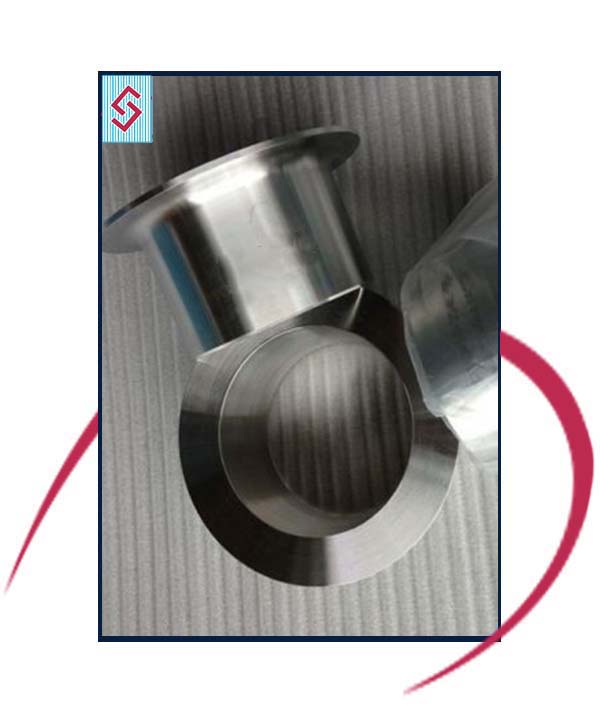

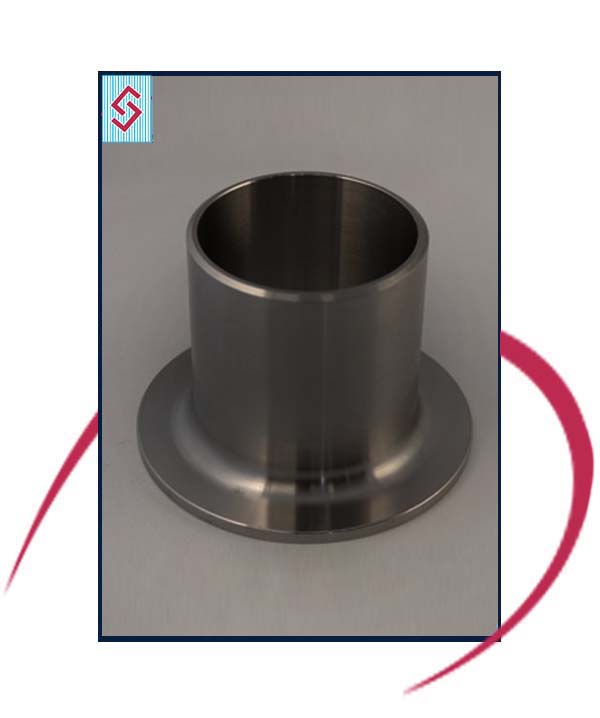

A stub end can be defined as a small tool that is added to a flange and this combination of a stub end and a flange is what we use for binding together different components of a pipe or any other equipment. The stub end can be made out of any alloy, be it inconel or titanium but it has the exact same function, that is to connect different parts and render them stable. There are long stub ends and short stub ends. The distinguishing factor between the two is the length of the flared end of the stub end, in the short pattern this flared part is shorter as compared to the long stub end. Nevertheless, the length of the stub end one chooses is based on the equipment or the grade of pipe and its dimensions and both the patterns serve the same function and have the same quality and properties when manufactured of the same material.

ANSI B16.9 Long Stub Ends, Stainless Steel Long Stub End, Carbon Steel Long Stub Ends, Duplex Steel Long Stub End, Super Duplex Steel Long Stub Ends, Inconel Long Stub Ends, Nickel Alloy Long Stub End, Hastelloy Long Stub Ends, Monel Long Stub Ends, Titanium Long Stub End, Alloy Steel Long Stub End, Incoloy Long Stub Ends, Long Stub Ends Manufacturer in Mumbai.

Different forms of combinations arise due to different types of flanges being connected to the suitable stub end, however, the function of the stub remains to connect different parts. And stainless steel stub ends fulfill this function efficiently and also comprise another essential and helpful property. Flexibility allows different components of machinery or different pipes of a piping system to operate productively with every part working in unison. Such an important trait is displayed by the monel short stub ends. Apart from this, the short stub ends are also known to possess strength and thermal stability, both qualities being very essential for harsh conditions. Cost is also not a problem when opting for short stub ends, since they are manufactured from cost-effective raw materials.

Now that we know the benefits short stub ends have to offer, some of the industries which use them actively include petroleum, chemical industry, fabrication industry, power generation plants, plumbing, oil refineries, food processing, etc.

Every product we manufacture goes through a set of tests and inspections before we dispatch them and short stub ends are no exception to this. Therefore, every short stubend we produce is tested thoroughly and then shipped off.

Other Pipe Fittings Products

Standard Specification

- Size

Welded Butt Weld Fittings : 1/2″ – 48″

- Dimensions

- Thickness

- Bending Radius

- Manufacturing process

- Fittings Type

Types of Long Joint Stub Ends

- ASME SA403 Long Stub Ends

- SS Long Stub End Supplier

- Stainless Steel Buttweld Long Stub Ends

- Stainless Steel 304 Long Stub Ends

- Stainless Steel Seamless Long Stub Ends

- SS Welded Long Stub Ends

- Duplex Steel Long Stub Ends

- Super Duplex Steel Long Stub End Stockist

- SS Long Stub End Manufacturer

- 254 SMO Butt Weld Long Stub End

- ANSI B16.9 SS Long Stub End Exporter

- Carbon Steel Long Stub Ends

- ASME SA420 CS Long Stub Ends

- Carbon Steel Buttweld Long Stub Ends

- CS Welded Long Stub Ends

- Alloy Steel Seamless Long Stub Ends

- Chrome Moly Long Stub End Supplier

- CS WPL6 Long Stub Ends

- Alloy Steel WP1 Long Stub End Stockist

- ASTM A860 WPHY 80 Long Stub End Manufacturer

- Low Temperature Carbon steel Long Stub End

- ANSI B16.9 CS Long Stub End Exporter

- Nickel Alloy 200 Long Stub Ends

- Hastelloy Long Stub End Supplier

- Monel Buttweld Long Stub Ends

- Inconel Welded Long Stub Ends

- Incoloy Seamless Long Stub Ends

- ASME SB366 High Nickel Alloy Long Stub Ends

- Titanium Long Stub Ends

- Alloy 20 Long Stub End Stockist

- Tantalum Long Stub End Manufacturer

- High Nickel Alloy Long Stub End

- ANSI B16.9 Alloy Long Stub End Exporter

Other Types Long Stub Ends

- Suppliers of Type A Long Stub Ends

- Butt weld Long Stub End Distributors

- Type C Long Stub Ends in Mumbai

- MSS SP 43 Long Stub Ends Manufacturer

- Type B Long Stub Ends Supplier

- EN 1092-1 Long Stub Ends

- Long Stub Ends Supplier in India

- Long Stub End Stock

- High Quality Long Stub Ends

- High Nickel Alloy Long Stub Ends

- ANSI B16.9 Long Stub End Dimensions

- ASTM A403 WP304 Long Stub End

- SS Long Stub End Manufacturer

- Buttweld Long Stub Ends Exporters

- Carbon Steel Long Stub End

- ASME B16.28 Buttweld Long Stub Ends Stockholder

- Butt Weld Long Stub Ends Exporter

- Low Temperature Carbon steel Long Stub Ends

- Long Stub Ends Stockist in Mumbai

- Steel Long Stub Ends Dealer in India

Long Stub Ends Application Industries

Searches Related to Long Stub Ends

We Export Long Stub Ends to Following Destinations

PRODUCTS

MATERIALS