RTJ Flanges Supplier

ANSI B16.48 RTJ Flanges Exporter, High Quality Ring Joint Flanges, Ring Type Joint Flanges Suppliers, RTJ Flanges, Industrial Ring Joint Flanges at Best Price, Austenitic Stainless Steel Ring Type Joint Flanges, RTJ Flanges, Ring Type Joint Flanges, ASME B16.5 RTJ Flange, MSS SP-44 Ring Type Joint Flanges, RTJ Flanges Supplier in India

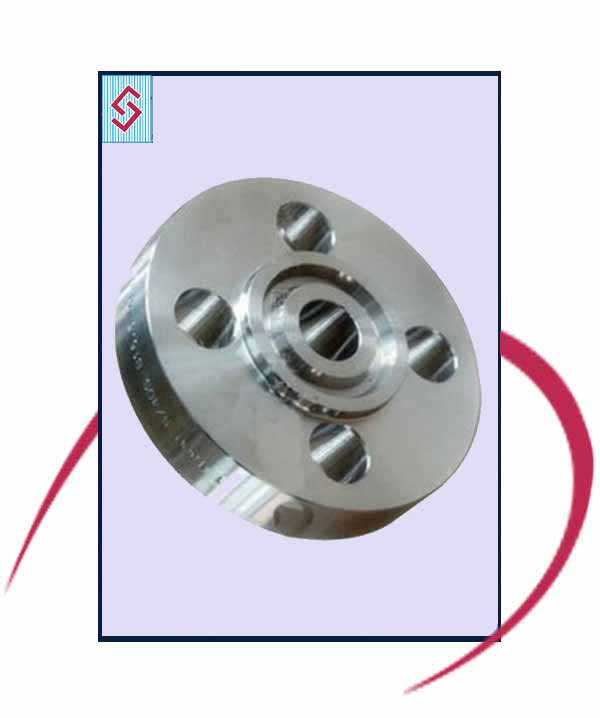

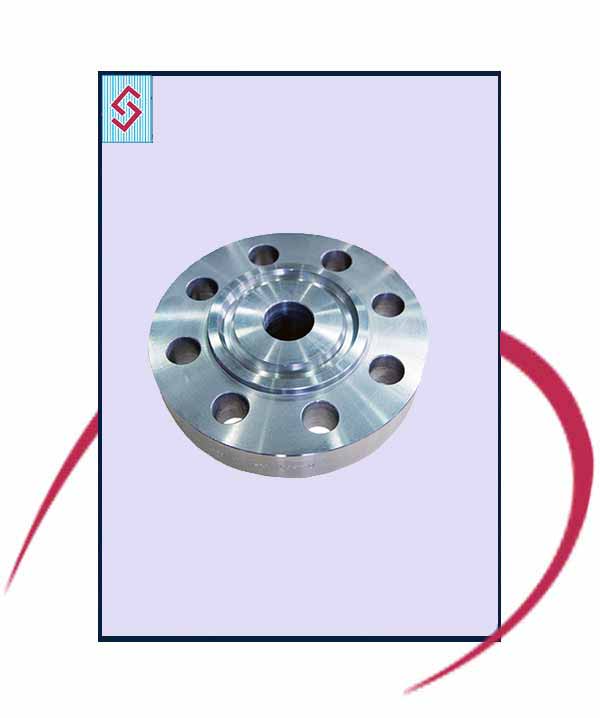

With different materials of pipes and different requirements of flanges, we get multiple types of flanges to choose from. Out of all the variations, the one which is widely used and most commonly selected by every industry is the Ring-Type Joint flanges or the RTJ flanges. These flanges have a hole bored into the hub or the central portion of the flange, surrounded by a metal ring, while on the outside we have the metal body which contains the bolt holes. The groove in the center is what attaches two pipes together without disrupting the flow of the contents within. When the bolts fasten the flanges to the pipes, the gasket surrounding the groove compresses on the insides, becoming narrower, this allows the flanges to intimately connect with the corresponding pipe. The conjugation, therefore, brought about by the RTJ flanges is tightly sealed, leaving no space for leakages and proofing the inner contents thoroughly.

Inconel Ring Joint Flanges, Duplex Steel RTJ Flange, Nickel Alloy RTJ Flange, Hastelloy Ring Type Joint Flanges, Monel RTJ Flanges, Incoloy RTJ Flanges, Alloy Steel Ring Type Joint Flange, Stainless Steel Ring Type Joint Flange, Carbon Steel Ring Joint Flanges, ANSI B16.47 Series A & B RTJ Flanges, Super Duplex Steel RTJ Flanges, Titanium Ring Type Joint Flange, RTJ Flanges Manufacturer in Mumbai.

The reason behind the widespread use of RTJ flanges in several applications is the fact that they are spill-proof, which also means that the inner components are not only protected from leaking out but are also defended from any form of external contamination. These flanges conjugate the pipes together with a considerable amount of strength, making them almost immune to mechanical strain or the pressure changes occurring within the system. When it comes to high pressure and temperature conditions, the RJT flanges operate exceptionally while withstanding and protecting themselves as well as the liquid or gaseous components inhabited by the pipes, against the harmful effects of elevated pressure and temperature. The flange is able to endure the rising temperature due to its heat resistance attribute that enables it to be thermally stable as the external temperature soars higher. Another important characteristic of the RTJ flanges is the resistance it displays against an impressively wide spectrum of corrosive agents.

Used as a replacement for raised flanges, the RTJ flanges are employed in a number of applications, including power plants, industrial pipeline systems, chemical processing, dairy industry, oil refineries, gas processing, fabrication industry, petrochemical, etc.

The integrity of every product we manufacture is tested through a series of suitable tests conducted by professionals in special testing facilities, regularly. After Which they are carefully packaged in safe boxes and then dispatched.

Standard Specification

- Size

- Dimensions

- Standard

- Pressure Class / Rating

- Flange Connect Type/ Face Type

Types of RTJ Flanges

- 254 SMO RTJ Flange

- Stainless Steel 304 Ring Joint Flanges

- Stainless Steel Ring Type Joint Flanges

- SS Ring Type Joint Flanges

- Stainless Steel RTJ Flanges

- Duplex Steel RTJ Flanges

- Super Duplex Steel Ring Type Joint Stockist

- SS RTJ Flange Manufacturer

- ASME SA182 Ring Joint Flanges

- SS Ring Type Joint Flange Supplier

- ANSI B16.5 SS RTJ Flange Exporter

- Low Temperature Carbon steel Ring Joint Flange

- ANSI B16.5 CS RTJ Flange Exporter

- Carbon Steel Ring Joint Flanges

- CS RTJ Flanges

- Alloy Steel Ring Type Joint Flanges

- A36 CS Ring Type Joint Flanges

- Chrome Moly RTJ Supplier

- ASME SA105 CS RTJ Flanges

- Carbon Steel IS 2062 Ring Type Joint Flanges

- Alloy Steel F5 RTJ Flange Stockist

- ASTM A694 F42 Ring Type Joint Manufacturer

- High Nickel Alloy Ring Joint Flange

- ANSI B16.5 Alloy Ring Type Joint Flange Exporter

- ASME SB564 High Nickel Alloy RTJ Flanges

- Nickel Alloy 200 Ring Type Joint Flanges

- Inconel RTJ Flanges

- Incoloy RTJ Flanges

- Hastelloy Ring Type Joint Flange Supplier

- Tantalum Ring Type Joint Manufacturer

- Monel Ring Joint Flanges

- Titanium RTJ Flanges

- Alloy 20 Ring Type Joint Stockist

Other Types RTJ Flanges

- ANSI B16.48 Ring Joint Flange Distributors

- BS4504 Ring Type Joint Flanges Supplier in India

- 2500 LBS RTJ Flange Stock

- 600 LBS Ring Joint Flanges

- High Nickel Alloy RTJ Flanges

- High Quality RTJ Flanges

- Monel 400 RTJ Flanges Manufacturer

- ANSI B16.5 200 Nickel Alloy Ring Type Joint Flange

- ANSI B16.47 RTJ Flanges in Mumbai

- Suppliers of SS Ring Type Joint Flanges

- SS PN40 Ring Joint Flange Manufacturer

- ASME B16.5 RTJ Flanges Stockholder

- 900 LBS Ring Joint Flanges Exporter

- Carbon Steel Ring Joint Flange

- Ring Type Joint Flange Dimensions

- Low Temperature Carbon steel Ring Joint Flanges

- 1500 LBS Ring Joint Flanges Stockist in Mumbai

- ASTM A182 F304 Ring Joint Flange

- Steel RTJ Flanges Dealer in India

- PN16 Ring Type Joint Flanges Exporters

RTJ Flanges Application Industries

Searches Related to RTJ Flanges

We Export RTJ Flanges to Following Destinations

Bhutan, Trinidad & Tobago, Sri Lanka, Kuwait, Croatia, France, Brazil, Kazakhstan, Japan, Colombia, Pakistan, Argentina, United Arab Emirates, Romania, Hong Kong, Nigeria, United States, Spain, Switzerland, Taiwan, Afghanistan, Bulgaria, Lithuania, Azerbaijan, South Africa, Portugal, Italy, Ghana, Mexico, Vietnam, Nigeria, Iraq, Oman, Qatar, Iran, South Korea, Tunisia, Poland, Ecuador, Yemen, Venezuela, Turkey, Israel, Gabon, Austria, Lebanon, New Zealand, Saudi Arabia, Peru, Greece, Algeria, Libya, United Kingdom, Slovakia, Sweden, Norway, Chile, Kenya, Bahrain, Australia, Costa Rica, Mexico, Angola, Serbia, Jordan, Indonesia, Iran, China, Singapore, Morocco, Denmark, Hungary, Estonia, Malaysia, Poland, Czech Republic, Thailand, Mongolia, Russia, Philippines, Ukraine, Bolivia, Chile, Belarus, Egypt, Bangladesh, Finland, Belgium, Canada, Netherlands.

Lumpur, Madrid, Al Khobar, Rio de Janeiro, Granada, Algiers, Jakarta, Chennai, Doha, Santiago, Tehran, Ulsan, Howrah, Vung Tau, Port-of-Spain, Ernakulam, Milan, Visakhapatnam, Toronto, Haryana, Coimbatore, Montreal, Kuala Kanpur, Thiruvananthapuram, Edmonton, New Delhi, Bhopal, Seoul, Houston, Faridabad, Rajkot, Ho Chi Minh City, Bogota, Dallas, Caracas, Jaipur, Atyrau, Geoje-si, Gurgaon, Nashik, Ranchi, Pune, La Victoria, Los Angeles, Petaling Jaya, Cairo, Hanoi, Riyadh, Lahore, Colombo, Aberdeen, Mumbai, New York, Secunderabad, Muscat, Jeddah, Thane, Baroda, Ludhiana, Ankara, Calgary, Brisbane, Navi Mumbai, Al Jubail, Ahvaz, Kuwait City, Istanbul, Ahmedabad, Indore, Courbevoie, Pimpri-Chinchwad, Hyderabad, Dubai, Jamshedpur, Manama, Sydney, Melbourne, Chandigarh, Dammam, Lagos, Surat, Kolkata, Nagpur, Bengaluru, Perth, Chiyoda, Bangkok, Sharjah, Abu Dhabi, Gimhae-si, Noida, Vadodara, Busan.

PRODUCTS

MATERIALS