Reducing Tees Supplier

Buttweld Reducing Tees, Butt weld Reducing Tees Exporter, Welded Reducing Tees, ASME B16.9 Reducing Tee, High Quality Reducing Tees, Seamless Reducing Tee, Austenitic Stainless Steel Reducing Tees, Industrial Reducing Tees at Best Price, Reducing Tees Suppliers, Reducing Tees Supplier in India

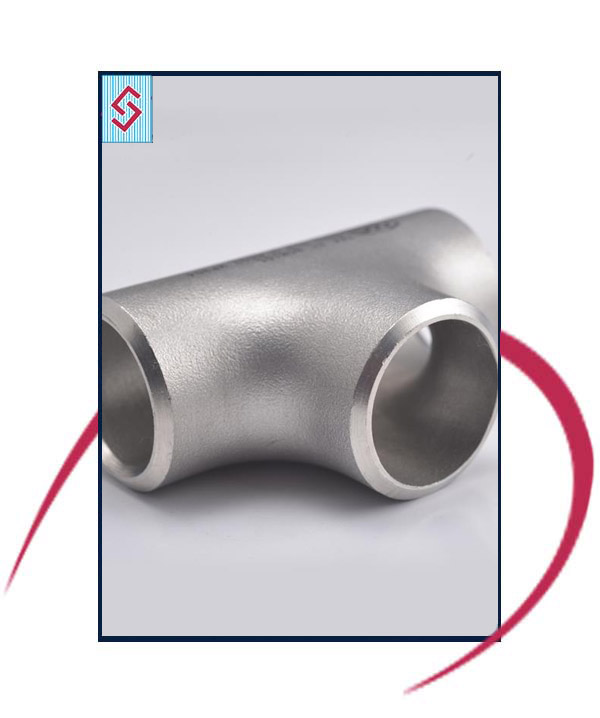

There are various twists and turns in a complex piping system and to ensure that the turn takes place smoothly, we use pipe fittings such as tees. Since the branches of the main pipes do not always have the same diameters, it is unwise to use tees comprising ends of equal diameters. Therefore, when the branching pipes have a smaller diameter than the main pipe, we make use of a monel reducing tee. Reducing tees are basically tees having one end of a smaller diameter to fit a smaller branch. The main function of the reducing tee remains to change the direction of flow by conjugating the primary pipe to the branching pipes at an angle of 90° with respect to the main pipe.

Super Duplex Steel Reducing Tees, Inconel Reducing Tees, Alloy Steel Reducing Tee, Incoloy Reducing Tees, Nickel Alloy Reducing Tee, ANSI B16.9 Reducing Tees, Stainless Steel Reducing Tee, Carbon Steel Reducing Tees, Duplex Steel Reducing Tee, Hastelloy Reducing Tees, Monel Reducing Tees, Titanium Reducing Tee, Reducing Tees Manufacturer in Mumbai.

The T-shaped, Hastelloy reducing tee is efficient in functioning throughout the operation because of its excellent traits. One such distinguishing property is the versatility in being able to join a pipe to one branch of the same diameter and the other to a slightly smaller diameter. An additional physical feature is the toughness they exhibit, both against mechanical strain and internal pressure conditions. Chemically, the stainless steel reducing tees manifest impressive corrosion resistance properties against a wide range of acids and organic solvents as well as gases. There are different forms of corrosion such as pitted or stress corrosion and the reducing tees have managed to tackle all of these forms with proficiency. Stress corrosion is caused due to rough conditions such as elevation in temperature and/or pressure. Both such factors are masterfully tolerated by reducing tees without getting damaged.

The alloy steel reducing tees are used in a number of industries throughout the globe and have been preferred over many different forms of pipe fittings because of the adaptable physical structure and its various physical and chemical aspects. They are actively used in drainage systems, plumbing, chemical processing, vacuum applications, petrochemical, etc.

Testing is a crucial part of our daily routine and is carried out post-production on every batch of products to verify its integrity and functionality. Once the tests and inspections are satisfactorily conducted, the products are then dispatched with the respective certificates.

Standard Specification

- Size

Welded Butt Weld Fittings : 1/2″ – 48″

- Dimensions

- Thickness

- Bending Radius

- Manufacturing process

- Fittings Type

Types of Reducing Tees

- Stainless Steel Buttweld Reducing Tees

- SS Welded Reducing Tees

- Stainless Steel Seamless Reducing Tees

- ASME SA403 Reducing Tees

- SS Reducing Tee Supplier

- Stainless Steel 304 Reducing Tees

- Duplex Steel Reducing Tees

- Super Duplex Steel Reducing Tee Stockist

- SS Reducing Tee Manufacturer

- 254 SMO Butt Weld Reducing Tee

- ANSI B16.9 SS Reducing Tee Exporter

- Carbon Steel Buttweld Reducing Tees

- CS Welded Reducing Tees

- Alloy Steel Seamless Reducing Tees

- ASME SA420 CS Reducing Tees

- Carbon Steel Reducing Tees

- Chrome Moly Reducing Tee Supplier

- CS WPL6 Reducing Tees

- Alloy Steel WP1 Reducing Tee Stockist

- ASTM A860 WPHY 80 Reducing Tee Manufacturer

- Low Temperature Carbon steel Reducing Tee

- ANSI B16.9 CS Reducing Tee Exporter

- Monel Buttweld Reducing Tees

- Inconel Welded Reducing Tees

- Incoloy Seamless Reducing Tees

- Nickel Alloy 200 Reducing Tees

- Hastelloy Reducing Tee Supplier

- ASME SB366 High Nickel Alloy Reducing Tees

- Titanium Reducing Tees

- Alloy 20 Reducing Tee Stockist

- Tantalum Reducing Tee Manufacturer

- High Nickel Alloy Reducing Tee

- ANSI B16.9 Alloy Reducing Tee Exporter

Other Types Reducing Tees

- Type C Reducing Tees in Mumbai

- MSS SP 43 Reducing Tees Manufacturer

- EN 1092-1 Reducing Tees

- Suppliers of Type A Reducing Tees

- Type B Reducing Tees Supplier

- Butt weld Reducing Tee Distributors

- Reducing Tees Supplier in India

- Reducing Tee Stock

- High Quality Reducing Tees

- High Nickel Alloy Reducing Tees

- SS Reducing Tee Manufacturer

- Buttweld Reducing Tees Exporters

- Carbon Steel Reducing Tee

- ANSI B16.9 Reducing Tee Dimensions

- ASTM A403 WP304 Reducing Tee

- ASME B16.28 Buttweld Reducing Tees Stockholder

- Butt Weld Reducing Tees Exporter

- Low Temperature Carbon steel Reducing Tees

- Reducing Tees Stockist in Mumbai

- Steel Reducing Tees Dealer in India

Reducing Tees Application Industries

Searches Related to Reducing Tees

We Export Reducing Tees to Following Destinations

PRODUCTS

MATERIALS