Reducing Flanges Supplier

Raised Face Reducing Flanges, Reducing Flat Face Flanges, ANSI B16.36 Reducing Flanges Exporter, High Quality Reducing Flanges, Reducing Flanges Suppliers, Flat Faced Reducing Flange, Industrial Reducing Flanges at Best Price, Reducing Flanges, MSS SP-44 Reducing Flanges, Austenitic Stainless Steel Reducing Flanges, Reducing Flanges, ASME B16.5 Reducing Flange, Reducing Flanges Supplier in India

- What is Reducing Flanges Flanges

- Standard Specification For Reducing Flanges Flanges

- Types of Reducing Flanges Flanges

- Other Types of Reducing Flanges Flanges Ready Stock

- Reducing Flanges Flanges Applications

- Searches Related to Reducing Flanges Flanges

- Export Destinations for Reducing Flanges Flanges

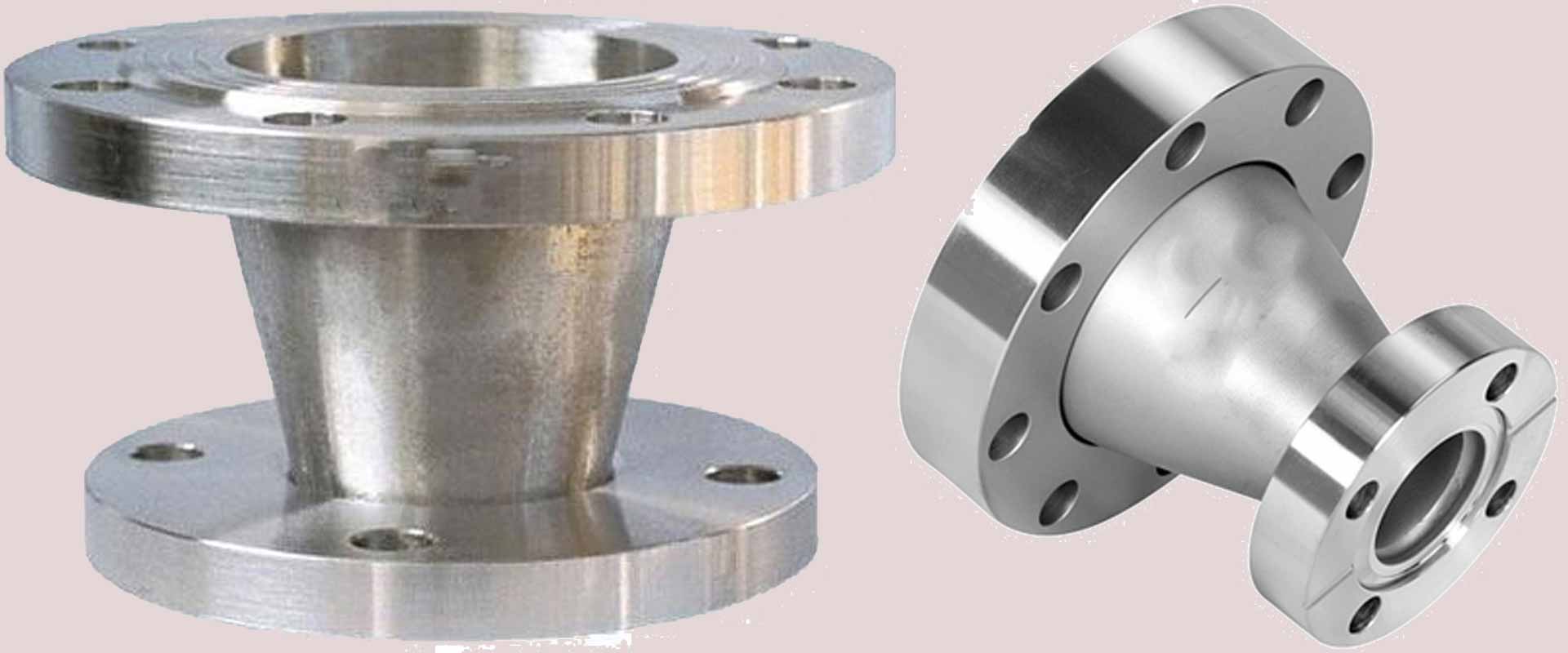

The flow between different pipes needs to be connected, for the system to operate effectively and this connection as we know is brought about by flanges. However, there are instances when the main pipe is to be connected either to a branch pipe which is generally of a smaller size, or to another pipe with a narrower bore. In such scenarios, we employ reducing flanges for connecting the two pipes. Reducing flanges are characterized by having a hub that is elevated and reduced in diameter, compared to the remaining body. The hub in a flange is the central portion within the metal ring containing the bolt holes. Therefore, the reducing flanges are made of 2 sides, one having a larger diameter, to be connected to the main pipe and the opposite side comprising a raised hub of smaller bore size, to connect with the narrower pipe respectively.

Duplex Steel Reducing Flange, Nickel Alloy Reducing Flange, Titanium Reducing Flange, Super Duplex Steel Reducing Flanges, Inconel Reducing Flanges, Alloy Steel Reducing Flange, Incoloy Reducing Flanges, Monel Reducing Flanges, Stainless Steel Reducing Flange, Carbon Steel Reducing Flanges, Hastelloy Reducing Flanges, ANSI B16.47 Series A & B Reducing Flanges, Reducing Flanges Manufacturer in Mumbai.

Since we now know how the reducing flange connects the two pipes and what it exactly is, it is interesting to delve into its physical and chemical properties. The distinguishing trait inhabited by the reducing flanges, and something very essential for a flange to comprise, is the strength it manifests against both, mechanical strain from the outside as well as the pressure it endures from within the pipes connected. This toughness in strenuous conditions as mentioned above continues to include rising temperature conditions. The reducing flanges retain their functionality while resisting the fatal effect of heat, as they tolerate operating in elevated temperatures. With heat resistance, the flanges also display corrosion resistance against a remarkably wide range of corrosive liquids and gases, including acids as well.

Standard Specification

- Size

- Dimensions

- Standard

- Pressure Class / Rating

- Flange Connect Type/ Face Type

Types of Reducing Flanges

- SS Reducing Flange Supplier

- Super Duplex Steel Reducing Stockist

- SS Reducing Flange Manufacturer

- 254 SMO Raised Face Reducing Flange

- Duplex Steel Reducing Flanges

- Stainless Steel Reducing Flanges

- SS Reducing Flat Face Reducing Flanges

- Stainless Steel Flat Face Reducing Flanges

- ASME SA182 Reducing Flanges

- Stainless Steel 304 Reducing Flanges

- ANSI B16.5 SS Reducing Flange Exporter

- Low Temperature Carbon steel Reducing Flange

- Carbon Steel IS 2062 Reducing Flanges

- Carbon Steel Ring Type Joint Reducing Flanges

- CS Reducing Flat Face Reducing Flanges

- Alloy Steel Flat Face Reducing Flanges

- Alloy Steel F5 Reducing Flange Stockist

- A36 CS Reducing Flanges

- ASTM A694 F42 Reducing Manufacturer

- ASME SA105 CS Reducing Flanges

- Chrome Moly Reducing Flanges Supplier

- ANSI B16.5 CS Reducing Flange Exporter

- ANSI B16.5 Alloy Reducing Flange Exporter

- ASME SB564 High Nickel Alloy Reducing Flanges

- Nickel Alloy 200 Reducing Flanges

- Incoloy Flat Face Reducing Flanges

- Alloy 20 Reducing Stockist

- Tantalum Reducing Manufacturer

- High Nickel Alloy Reducing Flange

- Inconel Reducing Flat Face Reducing Flanges

- Hastelloy Reducing Flange Supplier

- Titanium Reducing Flanges

- Monel Ring Type Joint Reducing Flanges

Other Types Reducing Flanges

- BS4504 Reducing Flanges Supplier in India

- Monel 400 Reducing Flanges Manufacturer

- ANSI B16.47 Reducing Flanges in Mumbai

- Suppliers of SS Reducing Flanges

- ANSI B16.5 200 Nickel Alloy Reducing Flange

- ANSI B16.48 Reducing Flange Distributors

- High Quality Reducing Flanges

- 600 LBS Reducing Flanges

- High Nickel Alloy Reducing Flanges

- 2500 LBS Reducing Flange Stock

- 900 LBS Reducing Flanges Exporter

- ASTM A182 F304 Reducing Flange

- SS PN40 Reducing Flange Manufacturer

- Carbon Steel Reducing Flange

- Reducing Flange Dimensions

- ASME B16.5 Reducing Flanges Stockholder

- Low Temperature Carbon steel Reducing Flanges

- 1500 LBS Reducing Flanges Stockist in Mumbai

- Steel Reducing Flanges Dealer in India

- PN16 Reducing Flanges Exporters

Reducing Flanges Application Industries

Searches Related to Reducing Flanges

We Export Reducing Flanges to Following Destinations

Romania, Hong Kong, Switzerland, Taiwan, Afghanistan, Bulgaria, Lithuania, Nigeria, Nigeria, Iraq, Oman, Qatar, Iran, South Korea, United States, Spain, South Africa, Portugal, Italy, Ghana, Mexico, Vietnam, Bhutan, Trinidad & Tobago, Sri Lanka, Kuwait, Tunisia, Poland, Ecuador, United Arab Emirates, Croatia, France, Yemen, Venezuela, Turkey, Israel, Gabon, Austria, Lebanon, New Zealand, Saudi Arabia, Peru, Greece, Algeria, Libya, United Kingdom, Slovakia, Sweden, Norway, Chile, Kenya, Bahrain, Australia, Brazil, Kazakhstan, Japan, Colombia, Pakistan, Argentina, Azerbaijan, Costa Rica, Mexico, Angola, Serbia, Jordan, Indonesia, Iran, China, Singapore, Morocco, Denmark, Hungary, Estonia, Malaysia, Poland, Czech Republic, Thailand, Mongolia, Russia, Philippines, Ukraine, Bolivia, Chile, Belarus, Egypt, Bangladesh, Finland, Belgium, Canada, Netherlands.

Bogota, Visakhapatnam, Toronto, Haryana, Coimbatore, Montreal, Kuala Lumpur, Tehran, Ulsan, Howrah, Vung Tau, Madrid, Santiago, New Delhi, Bhopal, Seoul, Houston, Faridabad, Rajkot, Ho Chi Minh City, Al Khobar, Rio de Janeiro, Port-of-Spain, Ernakulam, Kanpur, Thiruvananthapuram, Edmonton, Dallas, Caracas, Milan, Granada, Algiers, Jakarta, Chennai, Doha, Jaipur, Atyrau, Geoje-si, Gurgaon, Nashik, Ranchi, Pune, La Victoria, Los Angeles, Petaling Jaya, Cairo, Hanoi, Riyadh, Lahore, Colombo, Aberdeen, Mumbai, New York, Secunderabad, Muscat, Jeddah, Thane, Baroda, Ludhiana, Ankara, Calgary, Brisbane, Navi Mumbai, Al Jubail, Ahvaz, Kuwait City, Istanbul, Ahmedabad, Indore, Courbevoie, Pimpri-Chinchwad, Hyderabad, Dubai, Jamshedpur, Manama, Sydney, Melbourne, Chandigarh, Dammam, Lagos, Surat, Kolkata, Nagpur, Bengaluru, Perth, Chiyoda, Bangkok, Sharjah, Abu Dhabi, Gimhae-si, Noida, Vadodara, Busan.

PRODUCTS

MATERIALS