Nickel Alloy Thredolets Supplier

Steel Sales Co. is a prominent distributor of metal and alloy products, such as the nickel alloy thredolets, that are skillfully manufactured with precision in highly-developed factories. The raw materials we employ for the process of fabricating the respective product are of pure grade and are procured from authentic sources only. This being said, we are a company that believes in the power of innovation and have and still are adopting innovative techniques, from manufacturing to handling and packaging the products.

NICKEL ALLOY 200 THREDOLETS, NICKEL ALLOY THREADED OUTLET FITTINGS, NICKEL THREDOLET SUPPLIERS, NICKEL THREADED OLET FITTINGS, NICKEL ALLOY THREDOLETS, NICKEL THREDOLETS AT BEST PRICE, NICKEL THREDOLET MANUFACTURERS, NICKEL ALLOY 201 THREDOLETS EXPORTER, ASME B16.11 NICKEL ALLOY THREDOLETS SUPPLIER IN INDIA.

- What is Nickel Alloy Thredolets

- Standard Specification For Nickel Alloy Thredolets

- Nickel Alloy Thredolets Equivalent Grades

- Types of Nickel Alloy Thredolets

- Other Types of Nickel Thredolets Ready Stock

- Nickel Alloy Thredolets Applications

- Searches Related to Nickel Alloy Thredolets

- Export Destinations for Nickel Alloy Thredolets

The thredolets made out of nickel alloy are among the several other types of pipe fittings with the major responsibility of connecting the run pipe to a branch pipe, diverting the flow by a particular angle which in this case is 90°. The structure of the olet consists of two ends, the former which connects to the main pipe is welded to it and the latter consists of a threaded pattern that is tightened around the end of the corresponding branch pipe. While the physical specifications of the thredolets secure the connection, the chemical composition of the alloys also contributes majorly to the bulk of the properties displayed by the nickel alloy thredolets. The fundamental element of nickel in the alloy is accompanied by other stabilizing additives such as manganese, carbon, silicon, sulfur, etc. which also play certain roles in bestowing the olet with excellent properties. For instance, manganese grants the alloy hardness and strength, with an improvement in its hot working properties.

NICKEL 2.4066 THREDOLETS, NICKEL ALLOY 2.4068 THREADED OLETS, ALLOY 200 THREDOLETS, NICKEL ALLOY N02201 THREDOLETS, ASTM B366 NICKEL 201 THREDOLETS, UNS N02200 THREDOLET, NICKEL THREADED BRANCH OUTLET STOCKIST, NICKEL THREADED OUTLETS, ASME SB 366 NICKEL THREDOLETS, NICKEL THREDOLET MANUFACTURER IN MUMBAI.

Just like an elevation in pressure can cause harmful effects on the alloy product, similarly, a decrease in the pressure can also produce undesirable effects. This is not a problem when nickel alloy thredolets are used to connect the main pipe to the branch pipe and therefore, these olet fittings are commonly used in applications operating at a lower pressure. Even though the pressure reduces, it is still important for the olet fittings to inhabit strength and this property is a key feature of nickel alloy thredolets. These alloy olets possess a high tensile strength which means that they are both tough and also display hardness, keeping them stable even in the presence of mechanical strain. The thredolets made of nickel alloy are known to exhibit excellent corrosion resistance properties against a number of acids, liquids, and gases, because of which they are able to operate even when they are exposed to such potential corrosive agents. All the traits attributed to the thredolets only in turn enhance its durability and make it long-lasting.

The applications in which the nickel alloy thredolets are actively used for its efficacy and adaptability are as follows: chemical processing industry, aircraft equipment, power plants, construction, heat exchangers, cell phones, transportation equipment, etc.

We strictly conduct tests on every product we manufacture and these tests are carried out in a separate testing facility, regularly. Inspections are also organized to check the factory conditions, periodically.

Standard Specification

- Specifications

- Size

1/2″ to 24″

- Length

3 mm to 200 mm

- Pressure Class

3000 LBS, 6000 LBS, 9000 LBS

- Dimensions

ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799

- Form

Thredolets, Threaded Outlets, Threaded Outlet, Threaded Outlet Fittings, Threaded Olet Fittings

Nickel Alloy Thredolets Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS |

| Nickel 200 | 2.4066 | N02200 |

| Nickel 201 | 2.4068 | N02201 |

Types of Nickel Alloy Thredolets

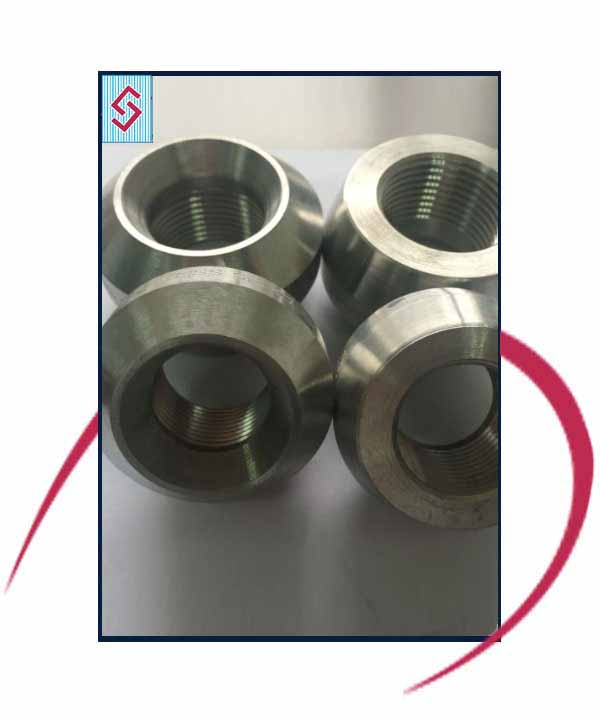

Nickel Alloy Thredolets

- Nickel Thredolets Manufacturer

- Nickel 2.4066 Thredolet

- Nickel Thredolets Exporter

- Nickel 2.4068 Thredolets

- Nickel UNS N02200 Thredolets

- Nickel Alloy UNS N02201 Thredolets

- Alloy 200 / 201 Thredolets

- Ni Alloy 2.4068 Thredolets

- Nickel 200 Thredolet

- Nickel 201 Thredolet

- Nickel Thredolets Supplier

- Nickel Thredolet in India

- Nickel Thredolet in Mumbai

- Nickel Alloy Thredolets Stockist

Nickel Alloy Threaded Outlets

- Nickel Alloy UNS N02201 Threaded Outlets

- Nickel 200 / 201 Threaded Outlet Stockist

- Nickel Threaded Outlet Manufacturer

- Nickel Alloy Threaded Outlet Fittings

- Nickel ASTM B366 Threaded Outlets

- Nickel 200 Threaded Outlet

- Alloy 201 Threaded Outlets Exporter

- Nickel UNS N02200 Threaded Outlet

- Nickel Threaded Outlets in Mumbai

- Nickel 2.4066 Threaded Outlets

- Ni 2.4068 Threaded Outlet Fittings

- Nickel Threaded Outlets Supplier

- Nickel Threaded Outlets in India

Nickel Alloy Threaded Olet Fittings

- Nickel 2.4066 Threaded Olet Fittings

- Ni 201 Threaded Olet Fittings

- Nickel Threaded Olet Fittings in India

- Nickel Threaded Olet Fittings in Mumbai

- Nickel Threaded Olet Fittings Exporter

- Ni 200 / 201 Threaded Olet Fittings

- Nickel 200 Threaded Olet Fittings

- Nickel Threaded Olet Fittings Supplier

- Alloy N02201 Threaded Olet Fittings

- Alloy 200 Threaded Olet Fittings

- Nickel UNS N02200 Threaded Olet Fitting

- Nickel Threaded Olet Fitting Manufacturer

- Nickel 2.4068 Threaded Olet Fittings

Other Types Nickel Alloy Thredolets

- UNS N02201 Thredolets Exporters

- Nickel Alloy 200 Threaded Branch Outlet

- Nickel Thredolet Fitting Stock

- Nickel Threaded Outlet Fittings Traders

- Nickel Threaded Outlets Distributor

- Nickel Alloy Threaded Outlets Importer

- Nickel N02200 Threaded Outlet Manufacturer

- Nickel 2.4066 Thredolets Outlet Fittings

- Nickel 2.4068 Threaded Olet Fittings

- Nickel Thredolet Branch Connection

- Nickel Thredolets Stockist in Mumbai

- Nickel 201 Threaded Outlet Supplier

- Nickel Threaded Branch Outlet Fittings

- Nickel Threaded Outlet Manufacturer

- Nickel Alloy Industrial Thredolets

- Nickel 200 Threaded Outlet Fittings

- Nickel Threaded Olet Fittings Supplier in India

- Nickel Alloy 201 Thredolets Stockholder

- Nickel Thredolets Dealer in India

- Nickel Thredolets Manufacturers

- Nickel Threaded Outlet in India

- ASTM B366 Nickel Thredolets in Mumbai

Nickel Alloy Thredolets Application Industries

Searches related to Nickel Alloy Thredolets

We Export Nickel Alloy Thredolets to Following Destinations

Iran, Czech Republic, Colombia, Australia, Angola, Greece, Iraq, Hong Kong, Mexico, Japan, Portugal, Ukraine, Pakistan, Ghana, Algeria, Taiwan, United States, New Zealand, Bulgaria, United Kingdom, Finland, Saudi Arabia, Peru, Chile, Russia, Libya, Kenya, Lebanon, Serbia, Gabon, France, South Korea, Indonesia, Iran, Bahrain, Afghanistan, China, Israel, Vietnam, Nigeria, Romania, Switzerland, Sri Lanka, Bhutan, Croatia, Poland, Turkey, Thailand, Belarus, Ecuador, Yemen, Azerbaijan, Norway, Lithuania, Italy, Sweden, Canada, Denmark, Philippines, Singapore, Oman, Bangladesh, United Arab Emirates, Austria, Estonia, Trinidad & Tobago, South Africa, Egypt, Bolivia, Mongolia, Hungary, Slovakia, Costa Rica, Argentina, Qatar, Poland, Chile, Brazil, Tunisia, Nigeria, Malaysia, Jordan, Kuwait, Belgium, Morocco, Venezuela, Spain, Kazakhstan, Mexico, Netherlands.

Ankara, Bhopal, La Victoria, Lagos, Milan, Hyderabad, Surat, Geoje-si, Granada, Nashik, Houston, Algiers, Ranchi, Vadodara, Kuala Lumpur, Istanbul, Indore, Manama, Mumbai, Jamshedpur, Colombo, Bangkok, Doha, Howrah, Chiyoda, Sharjah, Jakarta, Toronto, Madrid, Rajkot, Kolkata, Courbevoie, Noida, Calgary, Gurgaon, Dammam, Aberdeen, Bogota, Ludhiana, Petaling Jaya, Ernakulam, Seoul, Faridabad, Kanpur, Edmonton, Lahore, Ahvaz, Navi Mumbai, Pune, Baroda, Ahmedabad, Busan, Chandigarh, Atyrau, Secunderabad, New Delhi, Al Jubail, Rio de Janeiro, Hanoi, Al Khobar, Pimpri-Chinchwad, Muscat, Jeddah, Sydney, Brisbane, Riyadh, Abu Dhabi, Santiago, Port-of-Spain, Visakhapatnam, Thiruvananthapuram, Jaipur, Bengaluru, Ho Chi Minh City, Montreal, Caracas, Cairo, Perth, Chennai, Nagpur, Melbourne, Dallas, Ulsan, Dubai, Kuwait City, Coimbatore, Haryana, Vung Tau, Los Angeles, New York, Gimhae-si, Thane, Tehran.

MATERIALS

PRODUCTS