Inconel 625 Forged Fittings Supplier

Steel Sales Co is an all-rounder when it comes to the Inconel 625 Forges Fittings. We manufacture, export, supply, distribute and even stock these Inconel 625 Forged Fittings in order to serve our clients in future without any delay in the process of delivery and we trade not just in Inconel 625 Forged Fitting but also other Inconel 525 Products.

INCONEL 625 INDUSTRIAL FORGED FITTINGS AT BEST PRICE, ASTM B564 625 INCONEL FORGED FITTINGS SUPPLIERS, NICKEL ALLOY 625 FORGED FITTINGS EXPORTER, INCONEL® ALLOY 625 FORGED FITTINGS, ALLOY 625 FORGED FITTINGS, INCONEL 2.4856 FORGED FITTING, UNS N06625 FORGED FITTING, INCONEL 625 FORGED PIPE FITTINGS, ASME SB564 INCONEL 625 HIGH PRESSURE FORGED FITTINGS, INCONEL 625 FORGED FITTINGS SUPPLIER IN INDIA.

- What is Inconel 625 Forged Fittings

- Standard Specification For Inconel 625 Forged Fittings

- Inconel 625 Forged Fittings Equivalent Grades

- Types of Inconel 625 Forged Fittings

- Inconel 625 Socket Weld Fitting Chemical Composition

- Mechanical Properties of Alloy 625 Forged Fittings

- Other Types of 625 Inconel Threaded Fittings Ready Stock

- Inconel Grade 625 Forged Fittings Applications

- Searches Related to Inconel 625 Screwed Fittings

- Export Destinations for Inconel 625 Forged Fittings

The Inconel 625 Forged Fittings are supplied in the steel industry in several shapes and sizes that are of the standard class but the Inconel 625 Forged Fittings that are manufactured and distributed by us represent a quality which is one of our most important aspects that we value a lot. We also customize these Inconel 625 Forges Fittings according to the needs of our clients. Our Inconel 625 Forged Fittings are well-resistant to crevice and pitting corrosion. They function well in both lower and higher temperatures. They can very well combat the stress corrosion cracking caused by the chloride ions. These Inconel 625 Forged Fittings are also excellent at welding processes and resisting to creep.

INCONEL 625 FORGED UNION, INCONEL ALLOY 625 THREADED NIPPLE STOCKIST, INCONEL 625 FORGED ELBOW, ANSI B16.11 INCONEL 625 FORGED FITTINGS, INCONEL 625 FORGED CROSS, INCONEL 625 COUPLING, INCONEL 625 FORGED TEES, INCONEL 625 SOCKET WELD FITTINGS, INCONEL 625 FORGED CAP, INCONEL 625 THREADED FITTINGS, INCONEL 625 SCREWED FITTINGS, ALLOY 625 BUSHING, 625 INCONEL FORGED PLUGS, INCONEL 625 FORGED FITTINGS MANUFACTURER IN MUMBAI.

Inconel 625 Forged Fittings are fabricated in several proposes but all of these are applied to the construction sector only. The might can be used in general purposes too but the exact application must require the mechanical properties possessed BY THE Inconel 625 Forged Fittings, otherwise, it is impractical to do so. Hence, some of the most important applications of the Inconel 625 Forged Fittings are being applied to the petrochemical industry, power plants, furniture companies, modern architecture, water management projects, heat exchangers, dairy and food products, fluid piping, synthetic fibre, domestic appliances, pharmaceutically processing systems, energy industry marine and power transmission industry, and other chemical industries.

To send out an assurance, we conduct a few teats that evaluate the quality, material, reliability, and durability of the chemical properties of the Inconel 625 category and the mechanical properties of the Forged Fittings. Thus, the tests that are carried out on our Inconel 625 Forged Fittings are the hardness test, pitting resistance test, micro test, Intergranular corrosion test, macro test, positive material identification test, and many other chemical and mechanical tests that we essential for the examination.

Other Inconel Forged Fittings

Standard Specification

- Specifications

- Size

- Dimensions

- Types

- Pressure Rating

Socket-weld End-3000/ 6000/ 9000lbs

- Thread

- Specialized Manufacturer

Inconel 625 Screwed Fittings Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Inconel 625 | 2.4856 | N06625 | NCF 625 | NA 21 | ХН75МБТЮ | NC22DNB4M | NiCr22Mo9Nb |

Types of Inconel 625 Forged Fittings

Forged Elbows

- Inconel 625 Socket Weld Elbows Stockist

- Inconel 625 90 Deg Forged Elbows

- Inconel 625 90 Degree Forged Elbow Exporter

- ASTM B564 Inconel 625 BSPT Threaded Elbows Manufacturer

- Inconel 2.4856 Forged Elbows

- Inconel 625 Forged Elbow

- UNS N06625 Forged Elbows

- Inconel 625 45 Deg Threaded Elbows

- Alloy 625 NPT Screwed Elbow

- ASME SB564 Inconel 625 Forged Elbows

- ANSI B16.11 Inconel Alloy 625 Forged Elbows

- Inconel Alloy 625 Forged Elbows Supplier

Forged Tee

- Alloy 625 Socket Weld Tee Stockist

- ASME SB564 Inconel 625 Forged Tee

- Inconel 625 BSPT Threaded Tee Supplier

- Inconel 2.4856 Forged Tee

- ANSI B16.11 Inconel 625 Forged Tee

- Inconel 2.4856 Forged Tee Manufacturer

- UNS N06625 Forged Tee

- ASME SB564 Inconel 625 Forged Reducing Tees

- Inconel 625 Equal Forged Tee

- Inconel N06625 Screwed Tee

- Inconel 625 Unequal Forged Tee Exporter

- Nickel Alloy 625 NPT Threaded Forged Tee

- 625 Inconel ASTM B564 Forged Tee

Forged Cross

- ANSI B16.11 Inconel 625 Forged Cross

- ASTM B564 Inconel 625 Forged Cross

- 625 Inconel Unequal Forged Cross Exporter

- Inconel 2.4856 Equal Forged Cross

- Inconel 625 BSPT Screwed Forged Cross

- Alloy 625 Forged Reducing Cross

- Inconel N06625 Forged Cross

- Inconel 625 Forged Cross Supplier

- ASME SB564 Inconel 625 Forged Cross

- Inconel 625 NPT Threaded Cross

- Inconel N06625 Forged Cross

- Inconel 625 Socket Weld Cross Stockist

Coupling

- ANSI B16.11 Inconel 625 Forged Couplings

- ASTM B564 Inconel 625 Couplings

- UNS N06625 Couplings

- Inconel 2.4856 Couplings Supplier

- Inconel 625 Socket Weld Couplings Stockist

- Inconel 625 Full Coupling Exporter

- Alloy 625 Half Coupling

- Inconel 625 NPT Screwed Couplings

- Inconel 625 BSPT Threaded Coupling

- 625 Inconel Threaded Coupling

- Inconel 625 Couplings Manufacturer

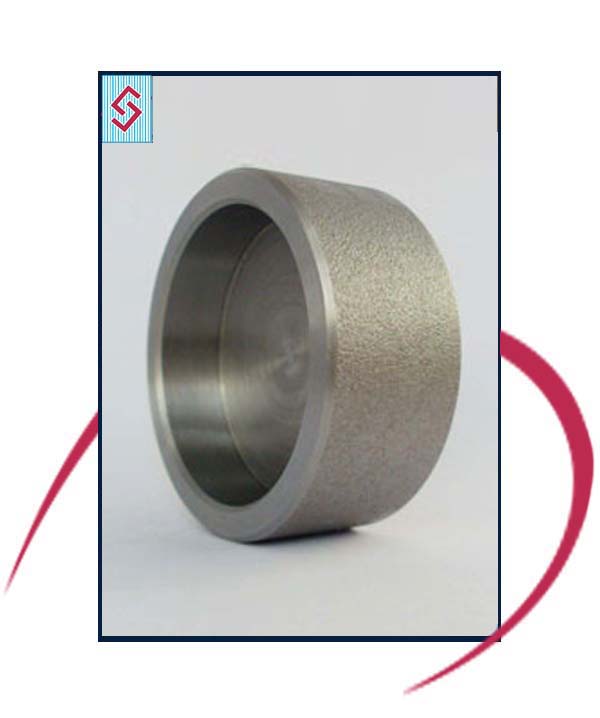

Forged Cap

- ANSI B16.11 Inconel 625 Forged Pipe End Cap

- ASTM B564 Inconel 625 Forged Caps

- 625 Inconel NPT Threaded Caps

- UNS N06625 Forged Caps

- Inconel Alloy 2.4856 Forged Cap

- 625 Inconel Forged End Cap Exporter

- Inconel 625 Screwed Caps Supplier

- Nickel Alloy 625 Socket Weld End Pipe Caps Stockist

- Inconel 2.4856 Forged Caps

- Inconel 625 BSPT Threaded Pipe Caps

- ASME SB564 Inconel 625 Forged End Caps

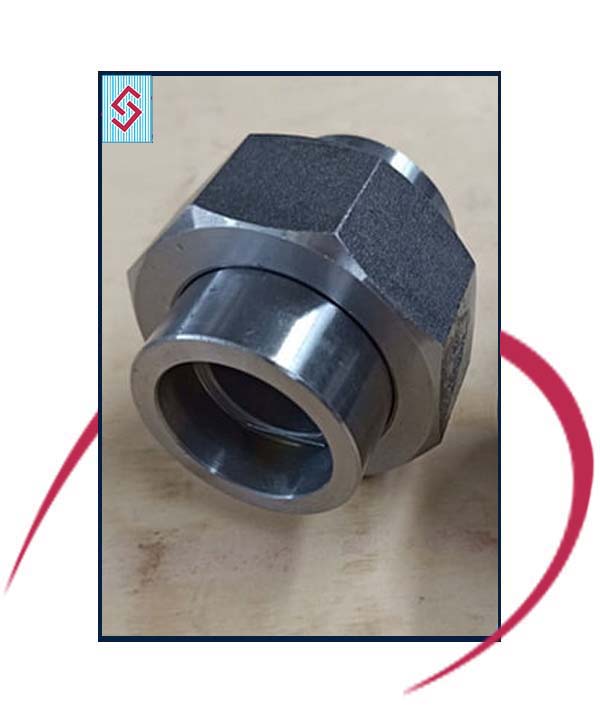

Union

- 625 Inconel Unions Supplier

- UNS N06625 Hex Unions

- Inconel 2.4856 BSPT Threaded Union

- ASTM B564 Inconel 625 Unions

- Inconel N06625 Screwed Union

- Inconel 2.4856 NPT Threaded Unions

- Alloy 625 Unions Manufacturer

- Inconel Alloy 625 Socket Weld Unions Stockist

- Inconel 625 Hex Head Union Exporter

- ASME SB564 Inconel 625 Unions

- ANSI B16.11 Inconel 625 Forged Union

Plug

- ASME SB564 Inconel 625 Plugs

- 625 Inconel Hex Head Plug Exporter

- ANSI B16.11 Inconel 625 Forged Plug

- Inconel N06625 Screwed Plug

- Inconel 625 NPT Threaded Plugs

- Alloy 625 BSPT Threaded Plugs Manufacturer

- Inconel 625 Square Plugs Stockist

- UNS N06625 Round Head Plugs

- Inconel 2.4856 Plug

- 625 Inconel Plugs Supplier

- ASTM B564 Inconel 625 Plugs

Bushing

- ASME SB564 Inconel Alloy 625 Bushings

- ASTM B564 Inconel 625 Bushings

- ANSI B16.11 Inconel 625 Forged Bushing

- UNS N06625 Bushings

- Inconel 625 Bushings Supplier

- Inconel 2.4856 NPT Threaded Bushings Manufacturer

- Inconel 625 Hex Head Bushing

- 625 Inconel Bushing Exporter

- Alloy 625 BSPT Screwed Bushings Stockist

- Inconel 625 Hex Head Bushing

- Inconel 2.4856 Threaded Bushings

Forged Nipple

- ANSI B16.11 Inconel 625 Forged Nipple

- Inconel 625 BSPT Threaded Swage Nipples

- Alloy 625 Threaded Nipples Stockist

- Inconel 2.4856 Forged Nipple

- Inconel N06625 Forged Nipple

- Inconel 625 Socket Weld Nipple Exporter

- Nickel Alloy 625 NPT Screwed Nipples

- Inconel 625 ASTM B564 Forged Nipples

- 625 Inconel Forged Nipples Supplier

- Inconel 2.4856 Forged Nipples Manufacturer

- ASME SB564 Inconel 625 Forged Nipples

ASTM B564 Inconel 625 Forged Fittings Chemical Composition

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

| Inconel 625 | 0.10 max | 0.50 max | 0.50 max | 0.015 max | – | 5.0 max | 58.0 min | 20.0 – 23.0 |

Inconel 625 Socket Weld Fittings Mechanical Properties

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Inconel 625 | 8.4 g/cm3 | 1350 °C (2460 °F) | Psi – 1,35,000 , MPa – 930 | Psi – 75,000 , MPa – 517 | 42.5 % |

Other Types Inconel 625 Forged Fittings

- Inconel 625 Swage Nipple Manufacturer

- Inconel N06625 Socket Weld Cross

- Inconel 625 High Pressure Forged Fittings

- Nickel Alloy 625 Threaded Bushing Exporters

- Inconel 625 Half Coupling Stockholder

- B564 Inconel 625 Socket weld Pipe Cap

- Inconel 625 Forged Threaded Hex Nipple

- 625 Inconel Threaded Cross Supplier

- Inconel 625 NPT Threaded Square Plug

- Inconel 625 Forged Tee

- Inconel 625 BSPT Screwed Union Stockist in Mumbai

- Inconel® Alloy 625 Forged Union

- Inconel Grade 625 Screwed Plug

- Inconel 625 NPT Threaded Tee in Mumbai

- Inconel 625 BSPP Screwed Coupling

- Inconel 2.4856 Street Elbow Dealer in India

- Inconel 625 Forged Socket weld Fittings

- Alloy 625 Unequal Cross Supplier in India

- UNS N06625 High Pressure Forged Fittings

- Inconel 625 3000LB Threaded Fittings

- Inconel 625 90 Degree Threaded Elbow Manufacturer

- ASTM B564 Inconel 625 45° Threaded Elbow

Inconel 625 Threaded Fittings Application Industries

Searches related to Inconel 625 Forged Fittings

We Export Inconel 625 Forged Fittings to Following Destinations

MATERIALS

PRODUCTS