inconel 617 Flanges SUPPLIER

Steel Sales Co is an established steel firm manufacturing and exporting Inconel 617 Flanges. We are assistive in the stocking of these Inconel 617 Flanges for future requisitions too. We are also associated with the larger stainless steel and super alloy stainless steel manufacturers for the dealing and distribution of the Inconel 617 Flanges through our company too. We are accessible for the customization of these Inconel 617 Flanges as per the shape, size, surface finish, thickness and rest of the dimensional requirements of our patrons.

617 INCONEL® ALLOY PIPE FLANGES EXPORTER, ALLOY 617 FLANGES, 617 INCONEL FLANGES EXPORTER, INCONEL 2.4663 FLANGE, UNS N06617 FLANGE, INCONEL 617 FLANGES, NICKEL ALLOY 617 FLANGES, INCONEL 617 INDUSTRIAL FLANGES AT BEST PRICE, ASME SB564 INCONEL 617 FLANGES, ASTM B564 INCONEL 617 FLANGES SUPPLIERS, INCONEL® ALLOY 617 FLANGES SUPPLIER IN INDIA.

- What is Inconel 617 Flanges

- Standard Specification For Inconel 617 Flanges

- Inconel 617 Flanges Equivalent Grades

- Types of Inconel 617 Flanges

- Inconel 617 Flange Chemical Composition

- Mechanical Properties of Inconel 617 Flanges

- Other Types of Inconel 617 Flanges Ready Stock

- Inconel 617 Flanges Applications

- Searches Related to Inconel 617 Flanges

- Export Destinations for Inconel 617 Flanges

The mixture of the Inconel 617 Flanges is a robust amalgamation of the elements added in them to develop an exceptional chemical composition for these flanges of the Inconel 617 grade. The metallic and non-metallic elements that constitute the basal section or the foundation of the Inconel 617 Flanges are nickel, cobalt, chromium, iron, molybdenum and a comparatively smaller amount of manganese too. There are other minuscule elements involved in the chemical combination are carbon, boron, silicon, and many more. Such an elemental structure when works together, provides a set of impeccable mechanical properties. These Inconel 617 Flanges are resistant to the actions of oxidizing processes. The Inconel 617 grade offers a collection of anti-corrosive features that exhibit very well and assist these flanges while functioning in a longer run. For the cold working of the Inconel 617 Flanges, they undergo the procedures of commercial cooling to derive effective results of the cooling. The resistance presented by the welded versions of Inconel 617 Flanges towards the creep rupture conditions is similar to that of the resistance to creep rupture displayed by the wrought versions of the Inconel 617 Flanges. While carrying out the entire welding method of the Inconel 617 Flanges, the post-welding step of the method can be avoided.

INCONEL 617 LAP JOINT FLANGES, INCONEL 617 SORF FLANGES, INCONEL 617 SOCKET WELD FLANGES, INCONEL® ALLOY 617 BLRF FLANGE, INCONEL 617 WELD NECK FLANGES, ALLOY 617 THREADED / SCREWED FLANGES, INCONEL 617 SPECTACLE BLIND FLANGE STOCKIST, INCONEL® ALLOY 617 RING TYPE JOINT (RTJ) FLANGES, INCONEL 617 SLIP ON FLANGES, ALLOY 617 BLIND FLANGE, INCONEL 617 FORGED FLANGES, INCONEL 617 FLAT FACE (FF) FLANGES, INCONEL 617 RAISED FACE (RF) FLANGES, INCONEL 617 FLAT FACE FLANGES, INCONEL 617 FLANGES MANUFACTURER IN MUMBAI.

The Inconel 617 Flanges engineered at Steel Sales Co are supplied to plenty of factories that belong to varying backgrounds of the industries. These Inconel 617 Flanges are also utilized in several governmental functions too. Hence, the main fabrications of the Inconel 617 Flanges are underwater sewage management, water supply, attachment of the valves, marine industry purposes and numerous other liquid-based applications.

Standard Specification

- Specifications

ASTM B564 / ASME SB564

- Size

- Dimensions

- Standard

- Pressure Class / Rating

- Flange Connect Type/ Face Type

- Specialized manufacturer of

inconel 617 Flanges Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS |

| Inconel 617 | 2.4663 | N06617 |

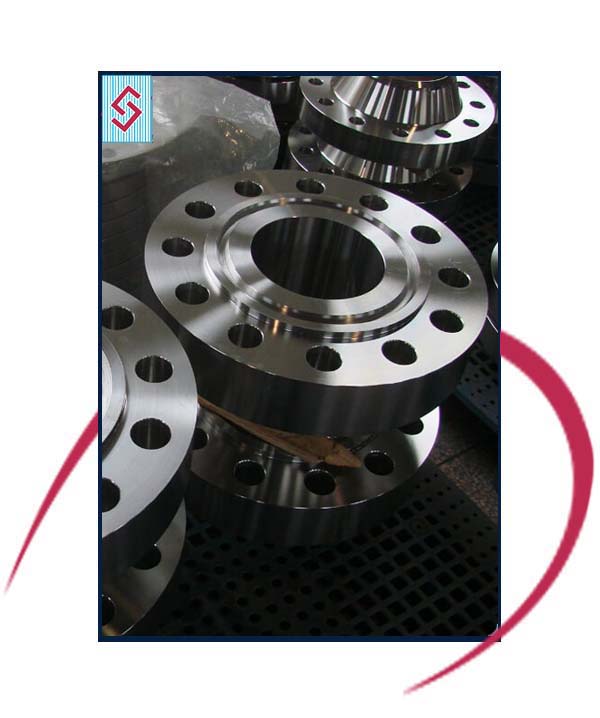

Types of inconel 617 Flanges

Slip On Flanges

- Inconel 617 RFSO Flanges

- Alloy 617 Raised Face Slip on Flange Exporter

- Inconel 617 Slip On Flange

- Nickel Alloy 617 SORF Flanges

- 617 Inconel Slip On Flanges Supplier

- ASTM B564 Alloy 617 Slip On Flanges Manufacturer

- Inconel 2.4663 Slip On Flange

- UNS N06617 Slip On Flanges

- Inconel 617 SORTJ Flange

- Inconel N06617 Slip On Flanges

- Alloy 617 Slip On Flanges Stockist

- ASME SB564 Inconel 617 Slip On Flanges

- Inconel® Alloy 617 SOFF Flanges

- 2.4663 Slip On Flanges

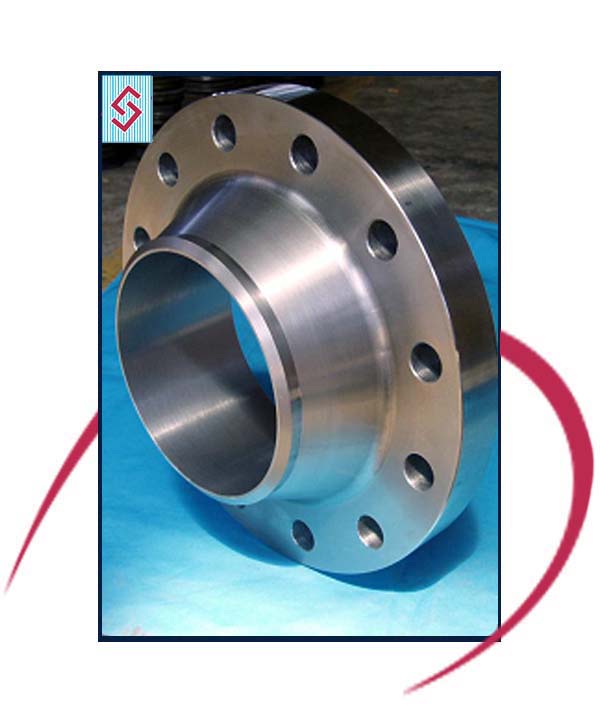

Weld Neck Flanges

- Nickel Alloy 617 WNRF Flanges

- ASME SB564 Alloy 617 Weld Neck Flanges

- ASTM B564 Inconel 617 Weld Neck Flanges

- 617 Inconel Welding Neck Flange

- Inconel 617 RFWN Flange

- Inconel 617 Weld Neck Flanges

- Inconel 617 Welding Neck Flanges Supplier

- UNS N06617 Weld Neck Flanges

- Inconel 617 WNFF Flange

- Inconel 2.4663 Weld Neck Flanges Manufacturer

- 2.4663 Welding Neck Flanges

- Alloy 617 Weld Neck Flanges Stockist

- Inconel 617 WNRTJ Flange

- 2.4663 Weld Neck Flange

Socket Weld Flanges

- Inconel 617 Socket Weld Flanges Stockist

- ASME SB564 Inconel 617 Socket Weld Flanges

- ASTM B564 Alloy 617 Socket Weld Flanges

- Inconel 2.4663 Socket Weld Flange

- Alloy N06617 Socket Weld Flanges

- UNS N06617 Socket Weld Flanges

- Inconel 617 Socket Weld Flange

- 617 Inconel Socket Weld Flanges Supplier

- 617 Inconel Socket Weld Flange Exporter

- Alloy 617 RFSW Flanges

- Inconel Alloy 617 SWRTJ Flanges

- Inconel 617 SWFF Flange

- 2.4663 Socket Weld Flanges

- Nickel Alloy 617 SWRF Flanges

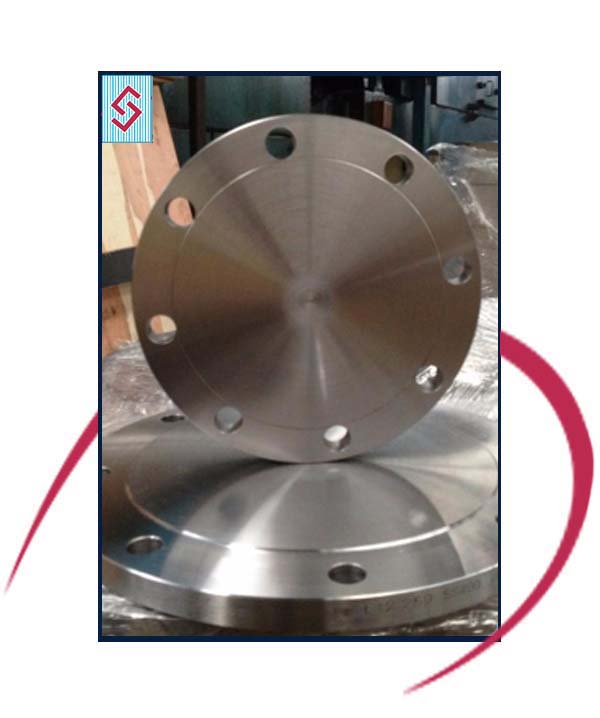

Blind Flanges

- 617 Inconel Raised Face Blind Flange

- Nickel Alloy 617 BLFF Flange

- Alloy N06617 Blind Flanges Manufacturer

- 2.4663 Blind Flange

- Inconel 617 Blind Flange

- Inconel 617 RFBL Flanges

- Inconel 617 BLRTJ Flange

- Alloy 2.4663 Blind Flange

- 617 Inconel Blind Flanges Supplier

- Inconel 617 BLRF Flanges

- ASTM B564 Alloy 617 Blind Flanges

- Inconel 617 Blind Flanges Stockist

- UNS N06617 Blind Flanges

Ring Type Joint Flanges

- Inconel 2.4663 RTJ Flanges

- ASME SB564 Inconel 617 Ring Type Joint Flanges

- Inconel N06617 RTJ Flanges

- UNS N06617 RTJ Flanges

- Inconel 617 RTJ Flanges

- ASTM B564 Alloy 617 Ring Type Joint Flanges

- 2.4663 Ring Type Joint Flange

- Nickel Alloy 617 RTJ Flanges Stockist

- 617 Inconel Ring Type Joint Flange Exporter

- Inconel 617 Ring Type Joint Flanges Supplier

Spectacle Blind Flanges

- ASME SB564 Inconel 617 Spectacle Blind Flanges

- UNS N06617 Spectacle Blind Flanges

- 617 Inconel Spectacle Blind Flange Exporter

- Nickel Alloy 617 Spectacle Blind Flanges Supplier

- Inconel 2.4663 Spectacle Blind Flanges

- ASTM B564 Inconel 617 Spectacle Blind Flanges

- Alloy N06617 Spectacle Blind Flanges

- 2.4663 Spectacle Blind Flange

- Inconel 617 Spectacle Blind Flanges Stockist

Long Weld Neck Flanges

- ASME SB564 Inconel 617 Long Weld Neck Flanges

- Alloy 2.4663 Long Weld Neck Flanges

- 617 Inconel Long Welding Neck Flanges Supplier

- 2.4663 Long Welding Neck Flange

- Inconel 617 Long Weld Neck Flanges Stockist

- UNS N06617 Long Welding Neck Flanges

- Nickel Alloy 617 LWN Flanges

- Alloy 617 Long Weld Neck Flange Exporter

Lap Joint Flanges

- ASME SB564 Inconel 617 Lap Joint Flanges

- 617 Inconel Lap Joint Flanges Supplier

- ASTM B564 Inconel 617 Lap Joint Flanges

- 617 Inconel Lapped Joint Flange Exporter

- Alloy 2.4663 Lapped Joint Flanges

- Alloy 617 Lap Joint Flanges Stockist

- UNS N06617 Lap Joint Flanges

- 2.4663 Lap Joint Flanges

- Alloy N06617 Lapped Joint Flanges

- Nickel Alloy 617 LJ Flanges

Threaded Flanges

- 617 Inconel Screwed Flange Exporter

- Alloy 617 Threaded Flanges Stockist

- 2.4663 Threaded Flange

- Alloy N06617 Screwed Flanges

- Inconel 617 Screwed Flanges

- Inconel 617 Threaded Flanges

- UNS N06617 Threaded Flanges

- Nickel Alloy 617 Threaded Flanges Supplier

- ASTM B564 Inconel 617 Threaded Flanges

- ASME SB564 Inconel 617 Threaded Flanges

inconel 617 Flanges Chemical Composition

| C | Mn | S | Si | Cr | Mo | Ni | Cu | Ti | Al | B | Co | Fe |

| 0.05-0.15 | 1.0 Max | 0.015 Max | 1.0 Max | 20.0-24.0 | 8.0-10.0 | 44.5 Min | 0.5 Max | 0.6 Max | 0.8-1.5 | 0.006 Max | 10.0-15.0 | 3.0 Max |

inconel 617 Flanges Mechanical Properties

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.1 g/cm3 | 1411 °C (2571 °F) | Psi – 80,000 , MPa – 550 | Psi – 30,000 , MPa – 205 | 30 % |

Other Types inconel 617 Flanges

- UNS N06617 Flanges Supplier in India

- ASME B16.5 Alloy 617 Long Weld Neck Flanges in India

- 617 Inconel Tongue & Groove Flanges

- Nickel Alloy 617 Plate Flanges Manufacturer

- Alloy 617 Class 300 Flat Flange in India

- Alloy Grade 617 Spades Ring Spacers Flanges

- Inconel 2.4663 Flanges Pressure Rating

- Inconel 617 SWRF Flanges

- Inconel 617 Loose Flange Stockholder in Mumbai

- 2.4663 Screwed Flanges Manufacturer in India

- Inconel 617 Nipo Flanges Exporters

- Inconel 617 Expander Flanges at Best Price

- ASTM B564 Inconel® Alloy 617 Nipo Flanges

- Inconel 617 High Hub Blinds Flanges

- UNS N06617 Reducing Flanges Supplier in India

- 617 Inconel Flanges Din Standard

- ASME SB564 Alloy 617 Expander Flanges Supplier

- Inconel 617 Loose Flanges Supplier

- ANSI B16.5 Inconel 617 Pipe Flange

- Inconel 617 Orifice Flanges Manufacturer

- Inconel 617 RTJ Flanges in Mumbai

- 2.4663 SORF Flanges Exporter

inconel 617 Flanges Application Industries

Searches related to inconel 617 Flanges

We Export inconel 617 Flanges to Following Destinations

Norway, Chile, Kenya, Bahrain, Indonesia, Iran, United States, Chile, Belarus, Egypt, Netherlands, Bhutan, Trinidad & Tobago, Ghana, Morocco, Sri Lanka, Kuwait, Tunisia, Poland, Ecuador, Yemen, Venezuela, Turkey, Mexico, Angola, Serbia, Jordan, Argentina, Azerbaijan, Mexico, Vietnam, Denmark, Hungary, Estonia, Malaysia, Poland, Czech Republic, Lithuania, Nigeria, Nigeria, Iraq, Oman, Qatar, Iran, South Korea, Thailand, Mongolia, Russia, Philippines, Ukraine, Bolivia, South Africa, Portugal, Italy, United Arab Emirates, Romania, Hong Kong, Switzerland, Australia, Costa Rica, Taiwan, Afghanistan, Bulgaria, Israel, Gabon, Austria, Lebanon, China, Singapore, New Zealand, Spain, Croatia, France, Brazil, Kazakhstan, Japan, Colombia, Pakistan, Saudi Arabia, Peru, Greece, Algeria, Libya, United Kingdom, Slovakia, Sweden, Bangladesh, Finland, Belgium, Canada.

PMilan, Granada, Algiers, Jakarta, Ranchi, Pune, Madrid, Al Khobar, Navi Mumbai, Rio de Janeiro, Kanpur, ort-of-Spain, Hanoi, Riyadh, Lahore, Colombo, Bogota, Visakhapatnam, Toronto, Haryana, Coimbatore, Montreal, Kuala Lumpur, Dallas, Caracas, Thiruvananthapuram, Edmonton, Aberdeen, Mumbai, New York, Secunderabad, Muscat, Jeddah, Thane, Baroda, Ludhiana, Ankara, Calgary, Brisbane, Dubai, Jamshedpur, Manama, Sydney, Melbourne, Chandigarh, Dammam, Lagos, Surat, Kolkata, Nagpur, Al Jubail, Ahvaz, Kuwait City, Istanbul, Ahmedabad, Indore, Courbevoie, Ernakulam, Abu Dhabi, Gimhae-si, Noida, Vadodara, Busan, Chennai, Doha, Santiago, Tehran, Ulsan, Howrah, Vung Tau, Jaipur, Atyrau, Geoje-si, Bengaluru, Perth, Chiyoda, Bangkok, Sharjah, Pimpri-Chinchwad, Hyderabad, La Victoria, Los Angeles, Petaling Jaya, Cairo, New Delhi, Bhopal, Seoul, Houston, Faridabad, Rajkot, Ho Chi Minh City, Gurgaon, Nashik.

MATERIALS

PRODUCTS