Incoloy 825 Forged Fittings Supplier

Steel Sales Co. is a universal location of the INCOLOY 825 Forged Fittings. We at Steel Sales Co., Mumbai manufacture and export the INCOLOY 825 Forged Fittings but along with that, we also distribute and even stock these INCOLOY 825 Forged Fittings and other steel products.

Incoloy 825 FORGED PIPE FITTINGS, NICKEL ALLOY 825 FORGED FITTINGS EXPORTER, Incoloy 2.4858 FORGED FITTING, Incoloy® ALLOY 825 FORGED FITTINGS, INCONEL 825 INDUSTRIAL FORGED FITTINGS AT BEST PRICE, ALLOY 825 FORGED FITTINGS, ASTM B564 825 Incoloy FORGED FITTINGS SUPPLIERS, ASME SB564 Incoloy 825 HIGH PRESSURE FORGED FITTINGS, UNS N08825 FORGED FITTING, Incoloy 825 FORGED FITTINGS SUPPLIER IN INDIA.

- What is Incoloy 825 Forged Fittings

- Standard Specification For Incoloy 825 Forged Fittings

- Incoloy 825 Forged Fittings Equivalent Grades

- Types of Incoloy 825 Forged Fittings

- Incoloy 825 Socket Weld Fitting Chemical Composition

- Mechanical Properties of Alloy 825 Forged Fittings

- Other Types of 825 Incoloy Threaded Fittings Ready Stock

- Incoloy Grade 825 Forged Fittings Applications

- Searches Related to Incoloy 825 Screwed Fittings

- Export Destinations for Incoloy 825 Forged Fittings

At Steel Sales Co., we have a patent of manufacturing and supplying the best standards of Incoloy 825 Forged Fittings. The Incoloy 825 Forged Fittings formulated by us display an excellent performance in acids, alkalis, and bases. While devising these Incoloy 825 Forged Fittings, we have used the ace qualities of all the alloys and made an extremely rich mixture which results in the Incoloy 825 category having unmatchable mechanical and chemical properties. The strong properties that that are ingested in the Incoloy 825 category and their products like their forged fittings are good resistance to chlorides and their stress cracking caused because of them. These Incoloy 825 Forged Fittings also avenge pitting and stress cracking. These forged fittings formed of Incoloy 825 are strong enough to resist without disfiguring themselves and be exposed to temperatures as high as 648OC to 760OC. This category of Incoloy 825 also exhibits high resistance against Intergranular corrosion. All the other properties that are inhibited into the chemical composition and the mechanical structure of the Incoloy 825 Forged Fittings aredurable functioning, heat resistance, excellent conductivity, enhanced service life, corrosion resistant, malleable, high strength, impeccable finish, and precisely designed.

Incoloy 825 THREADED FITTINGS, 825 Incoloy FORGED PLUGS, ALLOY 825 BUSHING, Incoloy 825 FORGED TEES, Incoloy 825 SOCKET WELD FITTINGS, Incoloy 825 COUPLING, Incoloy 825 FORGED CAP, Incoloy 825 FORGED ELBOW, Incoloy 825 SCREWED FITTINGS, Incoloy 825 FORGED CROSS, ANSI B16.11 Incoloy 825 FORGED FITTINGS, Incoloy ALLOY 825 THREADED NIPPLE STOCKIST, Incoloy 825 FORGED UNION, Incoloy 825 FORGED FITTINGS MANUFACTURER IN MUMBAI.

The Incoloy 825 Forged Fittings are applied and fabricated in multiple areas and are efficiently used for the industrial purposes. Few of the many applications of the Incoloy 825 Forged Fittings are that they are utilized in the beverage and food industry, petroleum refining, thermal, solar, and nuclear power generation industry, power plants, forged fitting accessories for the chemical industry, oil and gas processing industry, marine industry, dredging, dairy industry, and all other petrochemical and chemical factories.

To ensure the good functioning of the Incoloy 825 Forged Fittings, we conduct a few tests that assure our clients about the forged fittings durability, material, and the quality. Thus, the tests performed are the hardness test, micro test, macro test, hydrostatic test, positive material identification test, Intergranular corrosion test, and radiography.

Standard Specification

- Specifications

- Size

- Dimensions

- Types

- Pressure Rating

Socket-weld End-3000/ 6000/ 9000lbs

- Thread

- Specialized Manufacturer

Incoloy 825 Screwed Fittings Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN | OR |

| Incoloy 825 | 2.4858 | N08825 | NCF 825 | NA 16 | ЭП703 | NFE30C20DUM | NiCr21Mo | XH38BT |

Types of Incoloy 825 Forged Fittings

Forged Elbows

- Incoloy 825 Socket Weld Elbows Stockist

- Incoloy 825 90 Degree Forged Elbow Exporter

- Incoloy 2.4858 Forged Elbows

- Incoloy 825 Forged Elbow

- Incoloy 825 90 Deg Forged Elbows

- ASTM B564 Incoloy 825 BSPT Threaded Elbows Manufacturer

- UNS N08825 Forged Elbows

- Incoloy 825 45 Deg Threaded Elbows

- Alloy 825 NPT Screwed Elbow

- ANSI B16.11 Incoloy Alloy 825 Forged Elbows

- ASME SB564 Incoloy 825 Forged Elbows

- Incoloy Alloy 825 Forged Elbows Supplier

Forged Tee

- Incoloy 2.4858 Forged Tee Manufacturer

- Alloy 825 Socket Weld Tee Stockist

- Incoloy 825 BSPT Threaded Tee Supplier

- Incoloy 825 Equal Forged Tee

- Incoloy N08825 Screwed Tee

- Incoloy 2.4858 Forged Tee

- ANSI B16.11 Incoloy 825 Forged Tee

- ASME SB564 Incoloy 825 Forged Tee

- Nickel Alloy 825 NPT Threaded Forged Tee

- 825 Incoloy ASTM B564 Forged Tee

- Incoloy 825 Unequal Forged Tee Exporter

- UNS N08825 Forged Tee

- ASME SB564 Incoloy 825 Forged Reducing Tees

Forged Cross

- Incoloy 825 NPT Threaded Cross

- Incoloy 2.4858 Equal Forged Cross

- Incoloy 825 BSPT Screwed Forged Cross

- ANSI B16.11 Incoloy 825 Forged Cross

- ASTM B564 Incoloy 825 Forged Cross

- 825 Incoloy Unequal Forged Cross Exporter

- Incoloy 825 Forged Cross Supplier

- ASME SB564 Incoloy 825 Forged Cross

- Alloy 825 Forged Reducing Cross

- Incoloy N08825 Forged Cross

- Incoloy 825 Forged Cross

- Incoloy 825 Socket Weld Cross Stockist

Coupling

- Incoloy 825 Socket Weld Couplings Stockist

- ANSI B16.11 Incoloy 825 Forged Couplings

- ASTM B564 Incoloy 825 Couplings

- UNS N08825 Couplings

- 825 Incoloy Threaded Coupling

- Incoloy 825 Couplings Manufacturer

- Incoloy 825 BSPT Threaded Coupling

- Incoloy 825 Full Coupling Exporter

- Alloy 825 Half Coupling

- Incoloy 2.4858 Couplings Supplier

- Incoloy 825 NPT Screwed Couplings

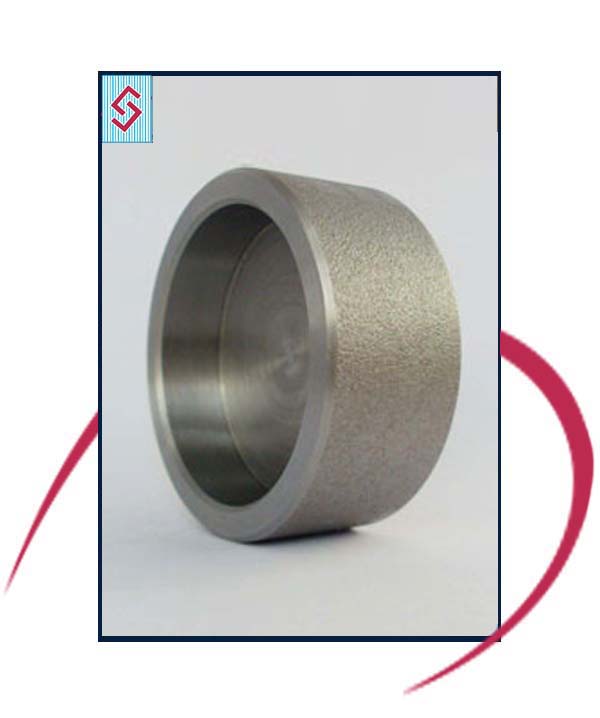

Forged Cap

- Incoloy Alloy 2.4858 Forged Cap

- 825 Incoloy Forged End Cap Exporter

- UNS N08825 Forged Caps

- 825 Incoloy NPT Threaded Caps

- ASTM B564 Incoloy 825 Forged Caps

- ANSI B16.11 Incoloy 825 Forged Pipe End Cap

- Incoloy 825 Screwed Caps Supplier

- Nickel Alloy 825 Socket Weld End Pipe Caps Stockist

- ASME SB564 Incoloy 825 Forged End Caps

- Incoloy 2.4858 Forged Caps

- Incoloy 825 BSPT Threaded Pipe Caps

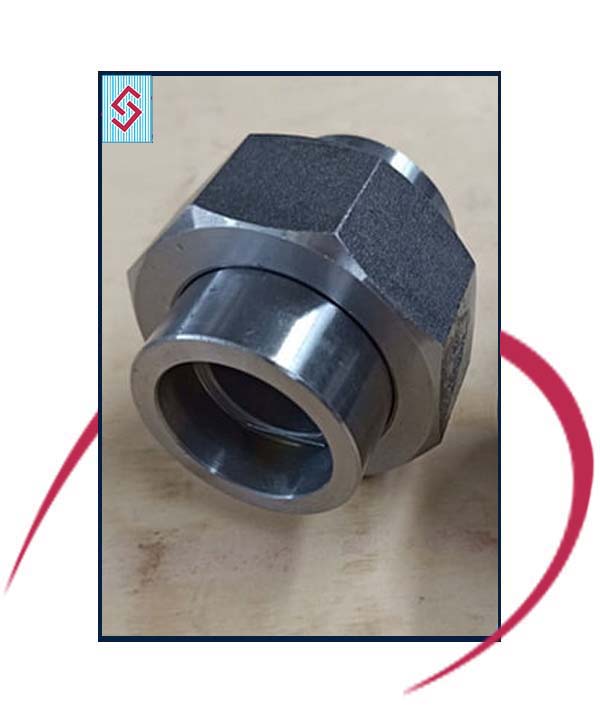

Union

- ANSI B16.11 Incoloy 825 Forged Union

- 825 Incoloy Unions Supplier

- UNS N08825 Hex Unions

- ASTM B564 Incoloy 825 Unions

- Incoloy 825 Hex Head Union Exporter

- Incoloy N08825 Screwed Union

- Incoloy 2.4858 NPT Threaded Unions

- Inconel 2.4858 BSPT Threaded Union

- Alloy 825 Unions Manufacturer

- Incoloy Alloy 825 Socket Weld Unions Stockist

- ASME SB564 Incoloy 825 Unions

Plug

- Alloy 825 BSPT Threaded Plugs Manufacturer

- UNS N08825 Round Head Plugs

- Incoloy 2.4858 Plug

- ASME SB564 Incoloy 825 Plugs

- ANSI B16.11 Incoloy 825 Forged Plug

- Incoloy 825 Square Plugs Stockist

- 825 Incoloy Hex Head Plug Exporter

- Incoloy N08825 Screwed Plug

- Incoloy 825 NPT Threaded Plugs

- 825 Incoloy Plugs Supplier

- ASTM B564 Incoloy 825 Plugs

Bushing

- Alloy 825 BSPT Screwed Bushings Stockist

- Incoloy 2.4858 Threaded Bushings

- ASME SB564 Incoloy Alloy 825 Bushings

- ASTM B564 Incoloy 825 Bushings

- Incoloy 2.4858 NPT Threaded Bushings Manufacturer

- ANSI B16.11 Incoloy 825 Forged Bushing

- UNS N08825 Bushings

- Incoloy 825 Hex Head Bushing

- 825 Incoloy Bushing Exporter

- Incoloy 825 Hex Head Bushing

- Incoloy 825 Bushings Supplier

Forged Nipple

- Incoloy N08825 Forged Nipple

- Alloy 825 Threaded Nipples Stockist

- Nickel Alloy 825 NPT Screwed Nipples

- ANSI B16.11 Incoloy 825 Forged Nipple

- Incoloy 825 BSPT Threaded Swage Nipples

- Incoloy 2.4858 Forged Nipples Manufacturer

- Incoloy 825 ASTM B564 Forged Nipples

- 825 Incoloy Forged Nipples Supplier

- Incoloy 2.4858 Forged Nipple

- ASME SB564 Incoloy 825 Forged Nipples

- Incoloy 825 Socket Weld Nipple Exporter

ASTM B564 Incoloy 825 Forged Fittings Chemical Composition

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr | Al | Ti |

| 825 | 0.05 max | 1.00 max | 0.5 max | 0.03 max | 1.50 – 3.00 | 22.00 min | 38.00 – 46.00 | 19.50 – 23.50 | 0.02 max | 0.06 – 1.20 |

Incoloy 825 Socket Weld Fittings Mechanical Properties

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 825 | 8.14 g/cm3 | 1400 °C (2550 °F) | Psi – 80,000 , MPa – 550 | Psi – 32,000 , MPa – 220 | 30 % |

Other Types Incoloy 825 Forged Fittings

- Incoloy 825 3000LB Threaded Fittings

- Incoloy Grade 825 Screwed Plug

- UNS N08825 High Pressure Forged Fittings

- Incoloy® Alloy 825 Forged Union

- Inconel 825 90 Degree Threaded Elbow Manufacturer

- Incoloy 825 NPT Threaded Tee in Mumbai

- Incoloy 825 BSPP Screwed Coupling

- Incoloy 2.4858 Street Elbow Dealer in India

- Incoloy 825 Forged Socket weld Fittings

- Alloy 825 Unequal Cross Supplier in India

- ASTM B564 Incoloy 825 45° Threaded Elbow

- B564 Incoloy 825 Socket weld Pipe Cap

- Incoloy 825 Swage Nipple Manufacturer

- Incoloy 825 Forged Threaded Hex Nipple

- Incoloy 825 Half Coupling Stockholder

- Nickel Alloy 825 Threaded Bushing Exporters

- Inconel 825 Forged Tee

- Incoloy N08825 Socket Weld Cross

- Incoloy 825 High Pressure Forged Fittings

- Incoloy 825 BSPT Screwed Union Stockist in Mumbai

- 825 Incoloy Threaded Cross Supplier

- Incoloy 825 NPT Threaded Square Plug

Incoloy 825 Threaded Fittings Application Industries

Searches related to Incoloy 825 Forged Fittings

We Export Incoloy 825 Forged Fittings to Following Destinations

MATERIALS

PRODUCTS