Forged Tee Supplier

HIGH PRESSURE FORGED TeeS, Socket Weld Equal Tee, Threaded Reducing Tee EXPORTER, FORGED Tee, AUSTENITIC STAINLESS STEEL FORGED TeeS, INDUSTRIAL FORGED TeeS AT BEST PRICE, THREADED FORGED TeeS, FORGED TeeS SUPPLIER IN INDIA, ASME B16.11 FORGED Tee, SCREWED FORGED Tee, Forged Unequal Tee SUPPLIERS.

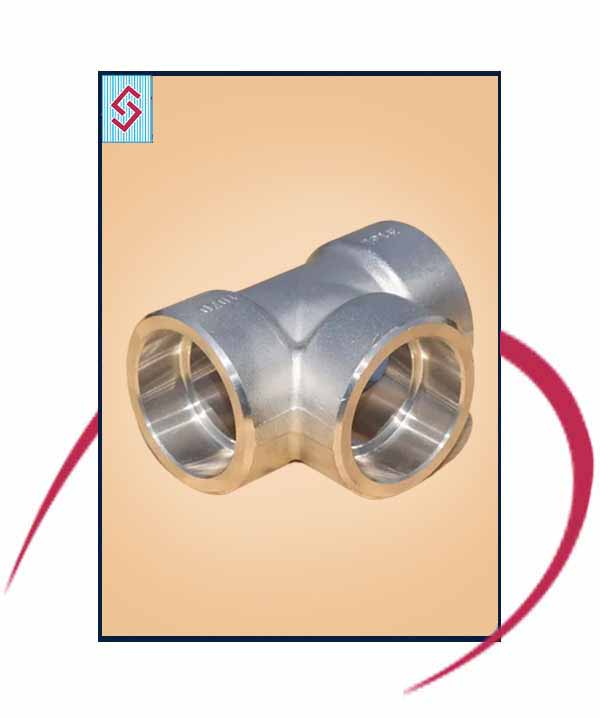

The piping component tee sounds like the alphabet ‘T’ and in reality, it does look like the alphabet itself, with 3 arms, two attached directly and the other attached at the junction of this attachment at an angle of 90°. With an arrangement as such, the primary function performed by the forged tee fittings is the divergence or branching of a single main pipe into two different pipes running at a length opposite in direction with respect to each other. Thus, the tee fittings are responsible for conjugating the pipe components of a complex piping system and of changing the direction and branching the main pipe into two different directions. This adaptability displayed by the tees in being able to join together three pipes while managing to diverge the flow is remarkable and is useful in several applications and industries.

SUPER DUPLEX STEEL FORGED TeeS, DUPLEX STEEL FORGED Tee, INCONEL FORGED TeeS, STAINLESS STEEL FORGED Tee, TITANIUM FORGED Tee, CARBON STEEL SOCKET WELD TeeS, NICKEL ALLOY FORGED Tee, INCOLOY SCREWED TeeS, ANSI B16.11 FORGED TeeS, SOCKET WELD Tee, ALLOY STEEL FORGED Tee, HASTELLOY THREADED TeeS, THREADED Tee, MONEL FORGED TeeS, FORGED TeeS MANUFACTURER IN MUMBAI.

An essential trait present in the versatile forged tee fittings is the strength and toughness they inhabit. This strength aids the tee in maintaining the system by not only withstanding the pressure changes occurring within the pipes but also tolerate the mechanical strain subjected to them from the outside in strenuous operating conditions. Connecting pipes require the tees to be exposed to possible corrosive pipe components and in order to function efficiently in the presence of such corrosive agents, the forged tee fittings exhibit impressive corrosion resistance properties. This property turns out to be very useful, especially in industries dealing with chemicals and gaseous compounds. Soaring temperatures are also tackled without it affecting the tee’s stability by the tee’s excellent thermal stability.

With such diverse properties manifested by the forged tee fittings, they are actively employed in several industries, and among them are, the marine industry, automotive, textile industry, gas refineries, waste treatment, chemical industry, petroleum, gas processing, etc.

Retaining the quality of our products throughout the process of production, handling and packaging is essential, and to ensure that it is maintained, we conduct tests after every step to check constantly if the quality of the product fulfills all the quality expectations of our clientele.

Standard Specification

- Size

- Dimensions

- Types

- Pressure Rating

Threaded End-2000lb/ 3000lb/ 6000lbs

Socket-weld End-3000/ 6000/ 9000lbs

- Thread

- Specialized Manufacturer

Types of Forged Tee

Socket Weld Tees

- Duplex Steel Socket Weld Tee

- Super Duplex Socket Weld Tees Stockist

- ASME SA182 SS Socket Weld Tees

- Monel Socket Weld Tees

- Inconel Socket Weld Tees Supplier

- Titanium Socket Weld Tee Manufacturer

- High Nickel Alloy Socket Weld Tees

- Carbon Steel Socket Weld Tee

- ANSI B16.11 Socket weld Unequal Tee Exporter

- Alloy Socket Weld Tees

- Nickel Alloy Socket Weld Tees

Threaded Tees

- Duplex Steel Threaded Tees

- Inconel Threaded Tees Supplier

- Super Duplex BSPP Threaded Tee Stockist

- ASME SA182 SS Threaded Tees

- Monel Threaded Unequal Tee

- ANSI B16.11 Threaded Tee Exporter

- Carbon Steel Threaded Tee

- Nickel Alloy Threaded Tees

- Alloy Steel Threaded Reducing Tee

- Titanium BSPT Threaded Tees Manufacturer

- High Nickel Alloy Threaded Tees

Screwed Tees

- Alloy Steel Screwed Tees

- ANSI B16.11 Screwed Tee Exporter

- Nickel Alloy Screwed Tees

- Monel NPT Screwed Tees

- ASME SA182 SS Screwed Tees

- High Nickel Alloy Screwed Tees

- Titanium Screwed Tees Manufacturer

- Inconel Screwed Tees Supplier

- Carbon Steel Screwed Tee

- Super Duplex Screwed Tee Stockist

- Duplex Steel Screwed Tees

Other Types of Forged Tee

- MSS SP-79 Forged Tees Manufacturer

- BS 3799 Forged Reducing Tee

- 9000lbs Forged Tees in Mumbai

- Forged Socket weld Tee Stock

- Socket Weld Forged Tee Distributors

- BSPP Threaded Tees Supplier in India

- High Quality Forged Threaded Tees

- High Nickel Alloy Forged Tees

- 3000lb Threaded Tees Supplier

- Suppliers of 2000lbs Forged Tees

- Low Temperature Carbon steel Forged Tees

- ANSI B16.11 Forged Tee Dimensions

- Alloy Steel Socket Weld Forged Tees Stockholder

- SS Forged BSPP Tee Manufacturer

- Socket Weld Forged Tees Exporters

- Socket Weld Forged Tees Exporter

- Carbon Steel Threaded Tee

- Steel Forged Tees Dealer in India

- ASTM A182 F304 Forged Tee

- Threaded NPT Tees Stockist in Mumbai

Forged Tee Application Industries

Searches Related to Forged Tee

We Export Forged Tee to Following Destinations

PRODUCTS

MATERIALS