Forged Lateral Outlet Supplier

SCREWED FORGED LATERAL OUTLET, ASME B16.11 FORGED LATERAL OUTLET, FORGED 45 DEGREE LATERAL OUTLET, HIGH PRESSURE FORGED LATERAL OUTLET, AUSTENITIC STAINLESS STEEL FORGED LATERAL OUTLET, THREADED FORGED LATERAL OUTLET, FORGED LATERAL OUTLET SUPPLIER IN INDIA, FORGED 45 DEGREE LATERAL OUTLET EXPORTER, FORGED LATERAL OUTLET SUPPLIERS, INDUSTRIAL FORGED LATERAL OUTLET AT BEST PRICE, SOCKET WELD FORGED LATERAL OUTLET.

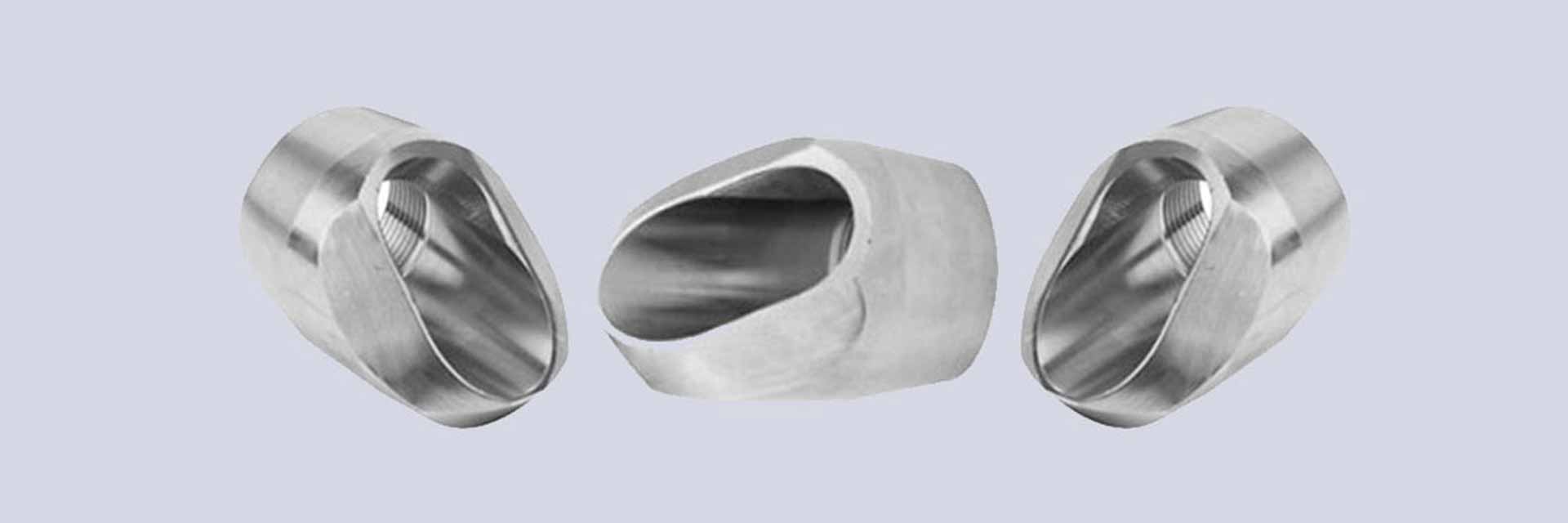

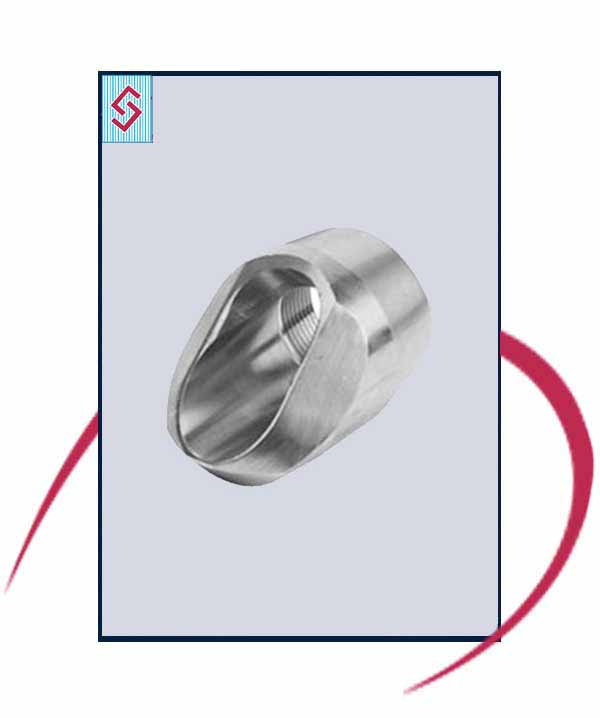

When the term ‘lateral’ appears, the first angle which perhaps just pops in the mind is the 45° angle and in this case, the lateral outlet does denote this particular angle. Outlets can be considered as a small unit bored into the pipe at a particular distance along the length of the pipe and this outlet connects the main pipe to another diverging pipe that diverts away from the main flow. Forged lateral outlets, therefore, can be considered as a pipe fitting that connects the main pipe to another branching pipe at an angle of 45°. The simple physical structure and the ease with which one can install the outlets to a pipe makes it a widely used piping component in several industries.

INCOLOY SCREWED LATERAL OUTLET, ALLOY STEEL FORGED LATERAL OUTLET, DUPLEX STEEL FORGED 45 DEG. THREADED LATERAL OUTLET, CARBON STEEL SOCKET WELD LATERAL OUTLET, NICKEL ALLOY 45° FORGED LATERAL OUTLET, STAINLESS STEEL FORGED LATERAL OUTLET, ANSI B16.11 FORGED LATERAL OUTLET, SOCKET WELD 45 DEG LATERAL OUTLET, HASTELLOY THREADED LATERAL OUTLET, INCONEL FORGED LATERAL OUTLET, MONEL FORGED LATERAL OUTLET, SUPER DUPLEX STEEL FORGED LATERAL OUTLET, TITANIUM FORGED LATERAL OUTLET, FORGED LATERAL OUTLET MANUFACTURER IN MUMBAI.

The primary function of the outlets is to divert a particular portion of the flow in a different direction and this means that the outlets will have to face the pressure changes accompanied by this movement. Keeping in mind the increased pressure fluctuations occurring during this diversion, the forged lateral outlets are equipped with remarkable strength. This tough and thick structure of the outlets enables them to withstand not only the pressure exerted on them from the inside but also the mechanical strain, if applied, from the outside. This strong trait of the outlets is coupled with the resistance it displays against aggressive chemicals, that is, corrosion resistance. The outlets are resistant to a number of corrosive liquids and gases which might be the components within the pipes to be connected and are, therefore, adept for usage in several industries as such. Thermally, the outlets manifest an impressive heat resistance against a large range of temperatures.

The applications which are famously employing forged lateral outlets include but are not limited to, the marine industry, power plants, oil refineries, plumbing, gas processing, petrochemical, pharmaceutical, sugar factories, fertilizer industry, chemical equipment, and food processing.

To safeguard the quality of the metal and alloy products, there is a list of norms and regulations set forth by the authoritative bodies and among these regulations is the compulsory ‘testing’ of the products before it is dispatched. This crucial step is conducted in our factories, regularly, so that you receive only the best quality of products.

Standard Specification

- Size

- Dimensions

- Types

- Pressure Rating

Threaded End-2000lb/ 3000lb/ 6000lbs

Socket-weld End-3000/ 6000/ 9000lbs

- Thread

–

- Specialized Manufacturer

Types of Forged Lateral Outlet

Socket Weld Lateral Outlet

- Nickel Alloy Socket Weld 45° Lateral Outlet

- High Nickel Alloy Socket Weld 45° Lateral Outlet

- Monel Socket Weld Lateral Outlet

- ASME SA182 SS 45 Degree Socket Weld Lateral Outlet

- Alloy 20 45 Degree Socket Weld Lateral Outlet

- Inconel Socket Weld Lateral Outlet Supplier

- Titanium Socket Weld Lateral Outlet Manufacturer

- Carbon Steel Socket Weld Lateral Outlet

- Super Duplex Socket Weld Lateral Outlet Stockist

- ANSI B16.11 Socket Weld Lateral Outlet Exporter

- Duplex Steel Socket Weld Lateral Outlet

Threaded Lateral Outlet

- Nickel Alloy Threaded 45° Lateral Outlet

- Super Duplex Threaded Lateral Outlet Stockist

- Carbon Steel Threaded Lateral Outlet

- Titanium Threaded Lateral Outlet Manufacturer

- Duplex Steel Threaded Lateral Outlet

- Monel Threaded Lateral Outlet

- Inconel Threaded Lateral Outlet Supplier

- ANSI B16.11 Threaded Lateral Outlet Exporter

- High Nickel Alloy Threaded 45° Lateral Outlet

- Alloy Steel 45 Degree Threaded Lateral Outlet

- ASME SA182 SS 45 Degree Threaded Lateral Outlet

Screwed Lateral Outlet

- Nickel Alloy Screwed 45° Lateral Outlet

- ANSI B16.11 Screwed Lateral Outlet Exporter

- Inconel Screwed Lateral Outlet Supplier

- Alloy Steel 45 Degree Screwed Lateral Outlet

- ASME SA182 SS 45 Degree Screwed Lateral Outlet

- Carbon Steel Screwed Lateral Outlet

- Monel Screwed Lateral Outlet

- Duplex Steel Screwed Lateral Outlet

- High Nickel Alloy Screwed 45° Lateral Outlet

- Super Duplex Screwed Lateral Outlet Stockist

- Titanium Screwed Lateral Outlet Manufacturer

Other Types of Forged Lateral Outlet

- Socket Weld Forged Lateral Outlet Distributors

- BS 3799 Forged 45 Degree Lateral Outlet

- 3000lb Threaded Lateral Outlet Supplier

- 9000lbs Forged Lateral Outlet in Mumbai

- MSS SP-79 Forged Lateral Outlet Manufacturer

- Suppliers of 2000lbs Forged Lateral Outlet

- Threaded Lateral Outlet Supplier in India

- Forged Socket weld Lateral Outlet Stock

- High Quality Forged Threaded Lateral Outlet

- High Nickel Alloy Forged Lateral Outlet

- ANSI B16.11 Forged Lateral Outlet Dimensions

- Socket Weld Forged Lateral Outlet Exporter

- Alloy Steel Socket Weld Forged Lateral Outlet Stockholder

- Low Temperature Carbon steel Forged Lateral Outlet

- SS Forged Lateral Outlet Manufacturer

- Steel Forged Lateral Outlet Dealer in India

- ASTM A182 F304 Forged 45 Degree Lateral Outlet

- Socket Weld Forged Lateral Outlet Exporters

- Carbon Steel Threaded Lateral Outlet

- Threaded Lateral Outlet Stockist in Mumbai

Forged Lateral Outlet Application Industries

Searches Related to Forged Lateral Outlet

We Export Forged Lateral Outlet to Following Destinations

PRODUCTS

MATERIALS