Forged Adapter Supplier

THREADED FORGED ADAPTERS, INDUSTRIAL FORGED ADAPTERS AT BEST PRICE, AUSTENITIC STAINLESS STEEL FORGED ADAPTERS, SOCKET WELD FORGED ADAPTERS, HIGH PRESSURE FORGED ADAPTERS, FORGED ADAPTERS EXPORTER, ASME B16.11 FORGED ADAPTER, SCREWED FORGED ADAPTER, FORGED ADAPTER, FORGED ADAPTERS SUPPLIERS, FORGED ADAPTERS SUPPLIER IN INDIA.

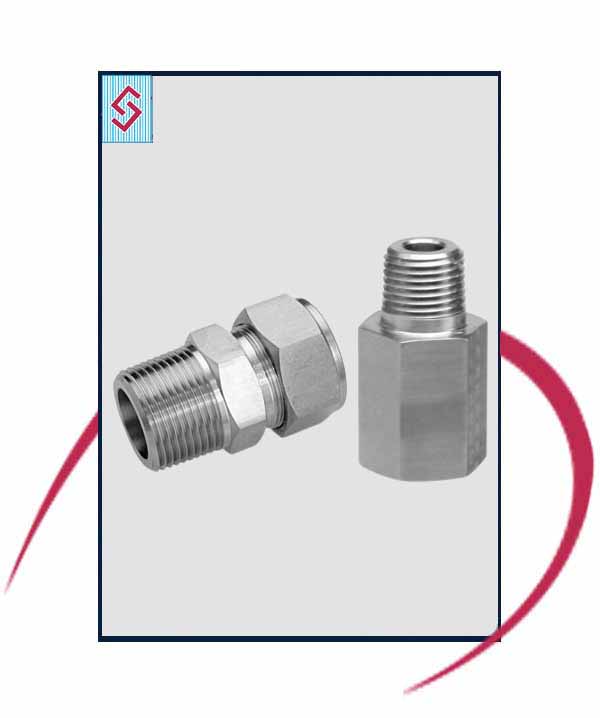

To adapt is to modify oneself or change oneself to adjust to the new situations by accepting something new or letting go of something old. This core meaning of the word adapt is what the adapter fitting is based on. Forged adapters are a type of pipe fittings that are used to connect together pipes of different diameters or materials, that is, it helps us to adapt to different sized or material pipes by connecting them to the entire piping system. Not all pipes have the same size or are made of the same material, nevertheless, every pipe is important for the stability and functioning of the complex piping system and needs to be connected. This connection is brought about by an adapter, which conjugates together two dissimilar pipes for the continuous flow and connection between them. Since different pipes have different sizes or materials, the adapter is modified to fit the particular requirements of the clientele.

INCONEL FORGED ADAPTERS, INCOLOY SCREWED ADAPTERS, STAINLESS STEEL FORGED ADAPTER, DUPLEX STEEL FORGED ADAPTER, ALLOY STEEL FORGED ADAPTER, CARBON STEEL SOCKET WELD ADAPTERS, NICKEL ALLOY FORGED ADAPTER, ANSI B16.11 SUPER DUPLEX STEEL FORGED ADAPTERS, SOCKET WELD ADAPTER, MONEL FORGED ADAPTERS, THREADED ADAPTER, TITANIUM FORGED ADAPTER, HASTELLOY THREADED ADAPTERS, FORGED ADAPTERS MANUFACTURER IN MUMBAI.

The operating conditions in industries aren’t always maintained at normal standard temperature, with the temperatures far exceeding the standard temperature, on a normal basis. This harsh industrial norm calls for a connecting tool that exhibits thermal stability and this is exactly what adapters provide us with. Forged adapter fittings display excellent heat-resistant properties against the harmful effects of elevated temperatures. The resistance of the adapters against heat is continued against the corrosive action of chemical liquids and gases as well. The adapters are also known for the remarkable strength they possess, partly because of their thickness, and are the trait responsible for maintaining the stability of the system.

With such abundant and useful characteristics to offer, the forged adapters are actively utilized for a number of operations in several applications, such as the food processing industry, petroleum industry, marine applications, plumbing, power generation plants, construction, architecture, paper, and pulp industries, gas processing, etc.

We regularly conduct a series of specific tests on every batch of products fabricated in our production units, with inspections being carried out occasionally.

Standard Specification

- Size

- Dimensions

- Types

- Pressure Rating

Threaded End-2000lb/ 3000lb/ 6000lbs

Socket-weld End-3000/ 6000/ 9000lbs

- Thread

- Specialized Manufacturer

Types of Forged Adapter

Socket Weld Adapters

- ANSI B16.11 Socket Weld Adapter Exporter

- Super Duplex Socket Weld Adapters Stockist

- Nickel Alloy Socket Weld Adapters

- ASME SA182 SS Socket Weld Adapters

- Titanium Socket Weld Adapter Manufacturer

- Duplex Steel Socket Weld Adapter

- Carbon Steel Socket Weld Adapter

- High Nickel Alloy Socket Weld Adapters

- Monel Socket Weld Adapters

- Inconel Socket Weld Adapters Supplier

- Alloy 20 Socket Weld Adapters

Threaded Adapters

- Carbon Steel Threaded Adapter

- Monel Threaded Adapters

- Inconel Threaded Adapters Supplier

- Alloy Steel Threaded Adapters

- Nickel Alloy Threaded Adapters

- Duplex Steel Threaded Adapters

- Titanium BSPT Threaded Adapters Manufacturer

- ANSI B16.11 Threaded Adapter Exporter

- Super Duplex BSPP Threaded Adapter Stockist

- ASME SA182 SS Threaded Adapters

- High Nickel Alloy Threaded Adapters

Screwed Adapters

- ASME SA182 SS Screwed Adapters

- High Nickel Alloy Screwed Adapters

- ANSI B16.11 Screwed Adapter Exporter

- Alloy Steel Screwed Adapters

- Monel NPT Screwed Adapters

- Duplex Steel Screwed Adapters

- Super Duplex Screwed Adapter Stockist

- Inconel Screwed Adapters Supplier

- Nickel Alloy Screwed Adapters

- Carbon Steel Screwed Adapter

- Titanium Screwed Adapters Manufacturer

Other Types of Forged Adapter

- 3000lb Threaded Adapters Supplier

- BSPP Threaded Adapters Supplier in India

- MSS SP-79 Forged Adapters Manufacturer

- Suppliers of 2000lbs Forged Adapters

- BS 3799 Forged Adapters

- Forged Socket weld Adapter Stock

- High Nickel Alloy Forged Adapters

- High Quality Forged Threaded Adapters

- 9000lbs Forged Adapters in Mumbai

- Socket Weld Forged Adapter Distributors

- Alloy Steel Socket Weld Forged Adapters Stockholder

- Carbon Steel Threaded Adapter

- Steel Forged Adapters Dealer in India

- Threaded NPT Adapters Stockist in Mumbai

- ASTM A182 F304 Forged Adapter

- SS Forged BSPP Adapter Manufacturer

- Socket Weld Forged Adapters Exporters

- Socket Weld Forged Adapters Exporter

- ANSI B16.11 Forged Adapter Dimensions

- Low Temperature Carbon steel Forged Adapters

Forged Adapter Application Industries

Searches Related to Forged Adapter

We Export Forged Adapter to Following Destinations

PRODUCTS

MATERIALS