Alloy Steel A234 WP9 Pipe Fittings Supplier

Steel Sales and Co has managed to maintain the reputation garnered through delivering and manufacturing products of rich quality, one such product being alloy steel A234 WP9 buttweld pipe fittings. The reason behind our good quality products is our strict diligence towards providing our clientele with only the best of the products without charging you with unreasonable expenses.

Cr-Mo WP9 Industrial Pipe Fittings at Best Price, CrMo WP9 Pipe Fittings, Alloy Steel WP9 Buttweld Fittings, A234 WP9 Alloy Steel Pipe Fittings, ASTM A234 Cr-Mo WP9 Pipe Fittings Suppliers, Chrome Moly WP9 Butt weld Pipe Fittings Exporter, Alloy Steel WP9 Pipe Fittings, Cr-Mo WP9 Pipe Fittings, Chrome Moly WP9 Pipe Fittings, ASME SA234 Alloy Steel WP9 Pipe Fittings Supplier in India.

- What is Alloy Steel WP9 Pipe Fittings

- Standard Specification For Alloy Steel WP9 Pipe Fittings

- Types of Alloy Steel WP9 Pipe Fittings

- Alloy Steel WP9 Buttweld Fitting Chemical Composition

- Mechanical Properties of Chrome Moly WP9 Pipe Fittings

- Other Types of WP9 Alloy Steel Seamless Fittings Ready Stock

- Alloy Steel Grade WP9 Pipe Fittings Applications

- Searches Related to Alloy Steel WP9 Welded Fittings

- Export Destinations for Alloy Steel WP9 Pipe Fittings

Belonging among the long list of chrome molly alloys, the alloy steel A234 WP9 buttweld pipe fittings comprise chromium, molybdenum, carbon, silicon, sulfur, manganese, and phosphorus. Buttweld fittings are an important part of piping solutions that are responsible for attaching different pipes together. Therefore, the chemical elements are combined in such a way and in such specific proportions that grant the fittings attain properties useful for them. For instance, manganese enriches the hot working properties of the fittings, making it easier for them to undergo processes involving heat treatment such as annealing, welding, all of which are aimed at enhancing the physical and chemical attributes of the fittings.

Alloy Steel WP9 Seamless Fittings, Chrome Moly WP9 Welded Fittings, Alloy Steel WP9 Buttweld Tee, Alloy Steel WP9 90 Deg Elbow, Chromium-Molybdenum Steel WP9 Pipe Nipple, CrMo WP9 Long Radius Bend, Alloy Steel WP9 Butt weld Unequal Cross, ANSI B16.9 Chrome Moly WP9 Pipe Fittings, WP9 CrMo SR Elbow, AS A234 WP9 Butt weld Pipe Fittings, Chromium-Molybdenum Steel WP9 Reducer, Alloy Steel WP9 Butt weld Fittings, Chrome Moly WP9 End Pipe Cap, AS WP9 Pipe Elbow, Alloy Steel WP9 BUTT WELD LR ELBOW, Alloy Steel WP9 Stub End Stockist, Alloy Steel A234 WP9 Two Joint Pipe Fittings, Chrome Moly WP9 Butt weld Pipe Fittings Manufacturer in Mumbai.

The corrosive properties of the alloy steel A234 WP9 buttweld pipe fittings are commendable and very useful for applications involving corrosive agents. The fittings have the potential to combat corrosive liquids such as acids and water without falling prey to any form of corrosion, especially intergranular corrosion. The pipes are mainly used to transport liquids and gases, therefore, this important trait comes in handy. Another essential factor of using the A234 WP9 grade of buttress fittings is the tensile strength they exhibit which helps them face mechanical strain and prevent stress corrosion. The ductility and durability of the alloy are impressive and are useful in stressful and harsh conditions.

The alloy steel A234 WP9 grade of flanged pipe fittings is popular among various, diverse industries, a few of the industries in which they are used are the chemical industry, pharmaceutical, energy production plants, condensers, petrochemical, heat exchangers, etc.

To ensure that the pipe fittings comply with the quality standards set forth by the respective national and international authorities, every pipe fittings are subjected to a series of tests and inspections on a regular basis. The products are also attached with a certification verifying their quality.

Standard Specification

- Specifications

- Size

Welded Butt Weld Fittings : 1/2″ – 48″

- Dimensions

- Thickness

- Bending Radius

- Manufacturing process

- Fittings Type

Types of Alloy Steel WP9 Pipe Fittings

Elbows

- CrMo WP9 90 Degree Elbow Exporter

- Alloy Steel WP9 SR Elbows Supplier

- Alloy Steel A234 WP9 Welded Elbow

- ASME SA234 CrMo WP9 Elbows

- ANSI B16.9 Alloy Steel WP9 Elbows

- CrMo WP9 Seamless Elbows Stockist

- A234 WP9 Alloy Steel LR Elbows

- Alloy Steel A234 WP9 45 Deg Buttweld Elbows

- ASTM A234 CrMo WP9 3D Elbows Manufacturer

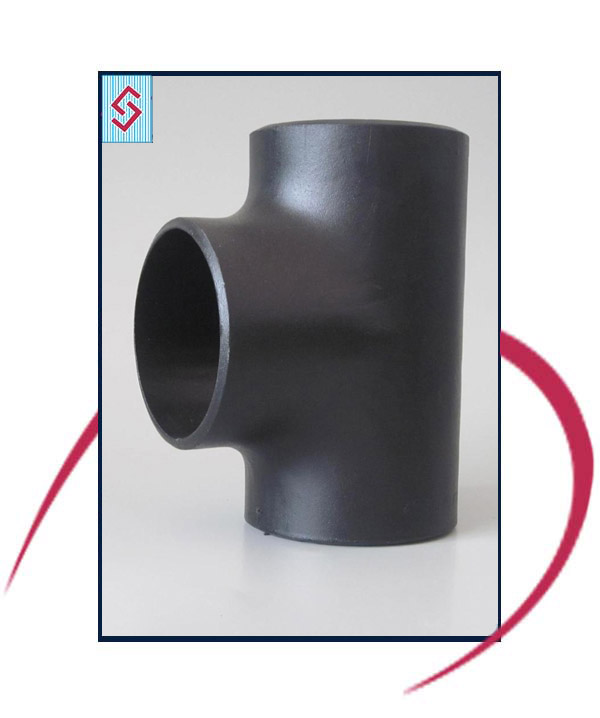

Tee

- ASTM A234 CrMo WP9 Butt weld Tee

- ASME SA234 Alloy Steel WP9 Tees

- Alloy Steel WP9 Reducing Tee Supplier

- Chrome Moly WP9 Seamless Tee Stockist

- A234 WP9 Alloy Steel Equal Tee

- ASME SA234 Alloy Steel WP9 Tee Manufacturer

- CrMo A234 WP9 Tee

- ANSI B16.9 Alloy Steel WP9 Tee

- Alloy Steel WP9 Equal Tee Exporter

Cross

- ASTM A234 CrMo WP9 Butt weld Cross

- ASME SA234 Alloy Steel WP9 Cross

- Alloy Steel WP9 Reducing Cross Supplier

- Chrome Moly WP9 Seamless Cross Stockist

- A234 WP9 Alloy Steel Equal Cross

- ASME SA234 Alloy Steel WP9 Cross Manufacturer

- CrMo A234 WP9 Cross

- ANSI B16.9 Alloy Steel WP9 Cross

- Alloy Steel WP9 Equal Cross Exporter

Reducer

- Chrome Moly WP9 Seamless Reducers Stockist

- ANSI B16.9 Alloy Steel WP9 Reducer

- Chrome Moly A234 WP9 Buttweld Reducer

- Alloy Steel A234 WP9 Pipe Reducers

- Cr-Mo WP9 Concentric Reducer Exporter

- Alloy Steel WP9 Reducers Supplier

- ASTM A234 Alloy Steel WP9 Buttweld Reducer

- Alloy Steel WP9 Eccentric Reducer Manufacturer

Cap

- Alloy Steel A234 WP9 Pipe End Caps

- ANSI B16.9 Alloy Steel WP9 Buttweld Cap

- ASTM A234 Cr-Mo WP9 End Caps Manufacturer

- ASME SA234 Alloy Steel WP9 End Pipe Caps

- Alloy Steel WP9 Caps Supplier

- Chrome Moly WP9 Seamless Caps Stockist

- AS WP9 End Pipe Cap Exporter

- Alloy Steel A234 WP9 Caps

Bend

- Cr-Mo WP9 Piggable Bend Exporter

- Alloy Steel A234 WP9 Long Radius Bends

- ANSI B16.9 Alloy Steel WP9 Bend Manufacturer

- ASME SA234 Chrome Moly WP9 Bends

- Alloy Steel WP9 Seamless Bends Stockist

- ASTM A234 Alloy Steel WP9 Pipe Bend

- Alloy Steel WP9 U Bends Supplier

- CrMo A234 WP9 Hot Induction Bend

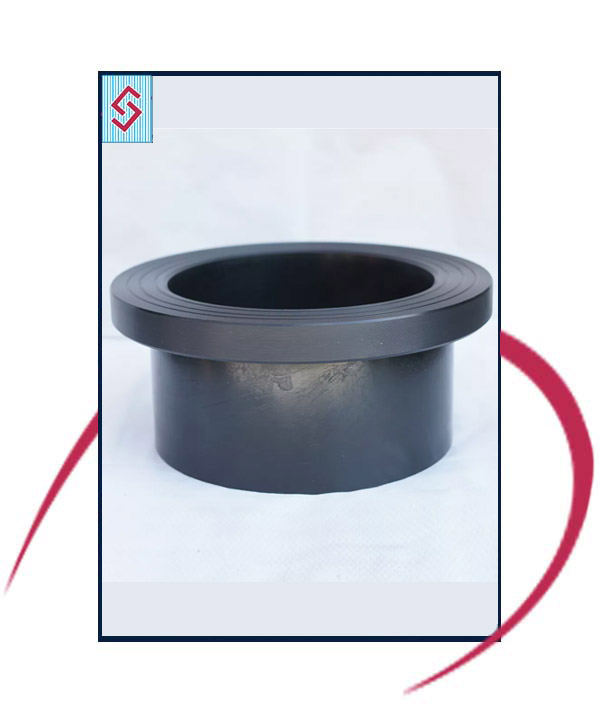

Stub End

- Cr-Mo WP9 Short Stub End Exporter

- Alloy Steel A234 WP9 Buttweld Stub Ends

- AS WP9 Lap Joint Stub Ends Stockist

- ANSI B16.9 Alloy Steel WP9 Stub End

- ASME SA234 CrMo WP9 Stub Ends Manufacturer

- Alloy Steel WP9 Stub Ends Supplier

- ASTM A234 Alloy Steel WP9 Stub Ends

- Alloy Steel A234 WP9 Long Stub Ends

Lateral Tee

- ANSI B16.9 Alloy Steel WP9 Lateral Tee Manufacturer

- Alloy Steel WP9 Lateral Tees Supplier

- ASME SA234 Alloy Steel WP9 Lateral Tees

- Cr-Mo WP9 Welded Lateral Tee Stockist

- ASTM A234 Alloy Steel WP9 Lateral Tee

- WP9 Chrome Moly Lateral Tee Exporter

- Alloy Steel A234 WP9 Buttweld Lateral Tee

- Alloy Steel A234 WP9 Lateral Tees

Nipple

- ASME SA234 AS WP9 Nipples Manufacturer

- Alloy Steel WP9 Nipples Supplier

- CrMo A234 WP9 Welded Nipples

- ANSI B16.9 Alloy Steel WP9 Nipple

- ASTM A234 Alloy Steel WP9 Buttweld Nipples

- CrMo WP9 Seamless Nipple Exporter

- Alloy Steel WP9 Buttweld Nipples Stockist

- Alloy Steel A234 WP9 Swage Nipples

ASTM A234 Alloy steel wp9 Pipe Fittings Chemical Composition

| Grade | C | Mn | Si | S | P | Cr | Mo |

| A234 WP9 | ≤0.15 | ≤0.6 | 1.00 | ≤0.03 | ≤0.03 | 8-10 | 0.90-1.10 |

alloy steel wp9 Seamless Fittings Mechanical Properties

| Grade | Tensile Strength (Mpa) | Yield Strength (Mpa) | Elongation % |

| A234 WP9 | 380 min | 585 min | ≥30 |

Other Types alloy steel wp9 Pipe Fittings

- Alloy Steel WP9 180 Deg Elbow in Mumbai

- Alloy Steel WP9 1D / 3D / 5D Elbow

- Suppliers of Chrome Moly WP9 End Pipe Cap

- Alloy Steel A234 WP9 Butt weld Equal Tee

- Alloy Steel A234 WP9 LR Elbow Supplier

- Alloy Steel WP9 Buttweld 90° Elbow Stock

- Grade WP9 Chrome Moly Fabricated Tee

- A234 WP9 Alloy Steel Concentric Reducer Supplier in India

- Alloy Steel WP9 Short Radius Elbows Manufacturer

- Sch 80 Chrome Moly WP9 Pipe Fittings

- A234 WP9 CrMo Short Radius Elbow Dealer in India

- Alloy Steel WP9 45 Degree Elbow Manufacturer

- Chrome Moly WP9 Pipe Fittings Dimensions

- Chromium-Molybdenum Steel WP9 Swage Nipple Fittings

- WP9 Alloy Steel 180° LR Return Bend

- ASTM A234 Cr-Mo WP9 Two Joint Pipe Fittings

- Alloy Steel WP9 Weldable 1.5D Elbow

- Chrome Moly A234 WP9 Lap Joint Stub Ends

- Alloy Steel A234 WP9 Eccentric Reducer Exporters

- Alloy Steel WP9 Equal Cross Stockholder

- Alloy Steel WP9 U Shape Bend Stockist in Mumbai

- Alloy Steel A234 WP9 90° SR Elbow

Alloy Steel WP9 Welded Fittings Application Industries

Searches related to Alloy Steel WP9 Pipe Fittings

We Export Alloy steel wp9 Pipe Fittings to Following Destinations

MATERIALS

PRODUCTS