Alloy Steel A234 WP11 Pipe Fittings Supplier

Steel Sales Co is a steadily rising firm that has established a prominent name in exporting and fabricating prime quality alloy steel A234 WP11 buttweld pipe fittings, among the several other high-standard, cost-efficient products. To fabricate various products, we make use of only those raw materials which pass all the tests conducted on them pre-production.

CrMo WP11 Pipe Fittings, Alloy Steel WP11 Buttweld Fittings, A234 WP11 Alloy Steel Pipe Fittings, ASTM A234 Cr-Mo WP11 Pipe Fittings Suppliers, Chrome Moly WP11 Butt weld Pipe Fittings Exporter, Alloy Steel WP11 Pipe Fittings, Cr-Mo WP11 Pipe Fittings, Chrome Moly WP11 Pipe Fittings, Cr-Mo WP11 Industrial Pipe Fittings at Best Price, ASME SA234 Alloy Steel WP11 Pipe Fittings Supplier in India.

- What is Alloy Steel WP11 Pipe Fittings

- Standard Specification For Alloy Steel WP11 Pipe Fittings

- Types of Alloy Steel WP11 Pipe Fittings

- Alloy Steel WP11 Buttweld Fitting Chemical Composition

- Mechanical Properties of Chrome Moly WP11 Pipe Fittings

- Other Types of WP11 Alloy Steel Seamless Fittings Ready Stock

- Alloy Steel Grade WP11 Pipe Fittings Applications

- Searches Related to Alloy Steel WP11 Welded Fittings

- Export Destinations for Alloy Steel WP11 Pipe Fittings

Based on iron, the alloy steel A234 WP11 buttweld pipe fittings are chemically distinct from other grades in having a lower amount of chromium of about 1-1.5%. The lowering of chromium is said to save the cost required to manufacture the pipe fittings and therefore, this grade is cost-effective. Molybdenum is another additive present in the alloy that plays a crucial role in improving the stability and thermal conductivity, both features enabling them to withstand operating in high-temperature conditions. Along with chromium, the quantity of carbon is also reduced. This reduction enhances the resistance of the alloy against intergranular corrosion. Manganese, silicon, sulfur, and phosphorus are other components of the alloy contributing largely towards the excellent properties they display.

Alloy Steel WP11 Buttweld Tee, Alloy Steel WP11 90 Deg Elbow, Chromium-Molybdenum Steel WP11 Pipe Nipple, CrMo WP11 Long Radius Bend, Alloy Steel WP11 Butt weld Unequal Cross, ANSI B16.9 Chrome Moly WP11 Pipe Fittings, WP11 CrMo SR Elbow, AS A234 WP11 Butt weld Pipe Fittings, Chromium-Molybdenum Steel WP11 Reducer, Alloy Steel WP11 Butt weld Fittings, Chrome Moly WP11 End Pipe Cap, AS WP11 Pipe Elbow, Alloy Steel WP11 Seamless Fittings, Chrome Moly WP11 Welded Fittings, Alloy Steel WP11 BUTT WELD LR ELBOW, Alloy Steel WP11 Stub End Stockist, Alloy Steel A234 WP11 Two Joint Pipe Fittings, Chrome Moly WP11 Butt weld Pipe Fittings Manufacturer in Mumbai.

The flanged fittings belonging to the grade A234 WP11 of alloy steel display appreciable heat resistance enabling them to operate at moderate as well as exceeding temperature conditions. This property of the alloy accompanied by the strength and stability they possess protects them against stress corrosion. The fittings are also known to be weldable, making it easier for them to undergo welding. Corrosive environments are difficult to withstand without corroding, but with A234 WP11 fittings, corrosion is easily combated. The alloy is said to be resistant against strong acids as well such as sulfuric acid, polyphonic acid, hydrochloric acid. The resistance against acids is extended towards including other forms of liquid solvents and corrosive environments as well.

The stable and versatile grade of threaded pipe fittings that is the alloy steel A234 WP11 is effectively used in petrochemical, gas processing, seawater equipment, plumbing, fabrication industry, off-shore drilling, etc.

The tests we conduct on every batch of products we produce consist of both chemical as well as physical tests focused on testing the properties, quality, and functioning of the particular product like the pipe fittings in consideration.

Other Alloy Steel Pipe Fittings

Standard Specification

- Specifications

- Size

Welded Butt Weld Fittings : 1/2″ – 48″

- Dimensions

- Thickness

- Bending Radius

- Manufacturing process

- Fittings Type

Types of Alloy Steel WP11 Pipe Fittings

Elbows

- Alloy Steel WP11 SR Elbows Supplier

- Alloy Steel A234 WP11 Welded Elbow

- ASME SA234 CrMo WP11 Elbows

- ANSI B16.9 Alloy Steel WP11 Elbows

- CrMo WP11 Seamless Elbows Stockist

- A234 WP11 Alloy Steel LR Elbows

- CrMo WP11 90 Degree Elbow Exporter

- Alloy Steel A234 WP11 45 Deg Buttweld Elbows

- ASTM A234 CrMo WP11 3D Elbows Manufacturer

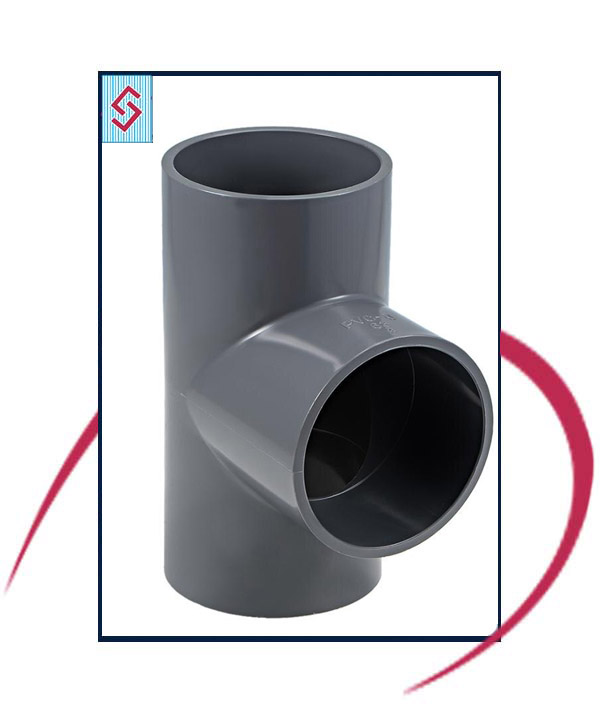

Tee

- ASME SA234 Alloy Steel WP11 Tees

- Alloy Steel WP11 Reducing Tee Supplier

- Chrome Moly WP11 Seamless Tee Stockist

- A234 WP11 Alloy Steel Equal Tee

- ASME SA234 Alloy Steel WP11 Tee Manufacturer

- ASTM A234 CrMo WP11 Butt weld Tee

- CrMo A234 WP11 Tee

- ANSI B16.9 Alloy Steel WP11 Tee

- Alloy Steel WP11 Equal Tee Exporter

Cross

- ASME SA234 Alloy Steel WP11 Cross

- Alloy Steel WP11 Reducing Cross Supplier

- Chrome Moly WP11 Seamless Cross Stockist

- A234 WP11 Alloy Steel Equal Cross

- ASTM A234 CrMo WP11 Butt weld Cross

- ASME SA234 Alloy Steel WP11 Cross Manufacturer

- CrMo A234 WP11 Cross

- ANSI B16.9 Alloy Steel WP11 Cross

- Alloy Steel WP11 Equal Cross Exporter

Reducer

- ANSI B16.9 Alloy Steel WP11 Reducer

- Chrome Moly A234 WP11 Buttweld Reducer

- Alloy Steel A234 WP11 Pipe Reducers

- Cr-Mo WP11 Concentric Reducer Exporter

- Chrome Moly WP11 Seamless Reducers Stockist

- Alloy Steel WP11 Reducers Supplier

- ASTM A234 Alloy Steel WP11 Buttweld Reducer

- Alloy Steel WP11 Eccentric Reducer Manufacturer

Cap

- Alloy Steel A234 WP11 Pipe End Caps

- ASTM A234 Cr-Mo WP11 End Caps Manufacturer

- ASME SA234 Alloy Steel WP11 End Pipe Caps

- Alloy Steel WP11 Caps Supplier

- ANSI B16.9 Alloy Steel WP11 Buttweld Cap

- Chrome Moly WP11 Seamless Caps Stockist

- AS WP11 End Pipe Cap Exporter

- Alloy Steel A234 WP11 Caps

Bend

- Alloy Steel A234 WP11 Long Radius Bends

- ANSI B16.9 Alloy Steel WP11 Bend Manufacturer

- ASME SA234 Chrome Moly WP11 Bends

- Alloy Steel WP11 Seamless Bends Stockist

- Cr-Mo WP11 Piggable Bend Exporter

- ASTM A234 Alloy Steel WP11 Pipe Bend

- Alloy Steel WP11 U Bends Supplier

- CrMo A234 WP11 Hot Induction Bend

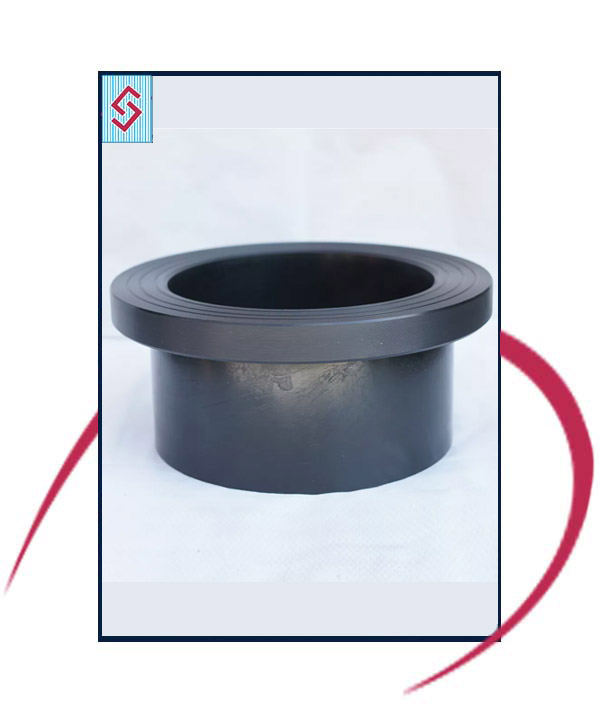

Stub End

- Alloy Steel A234 WP11 Buttweld Stub Ends

- AS WP11 Lap Joint Stub Ends Stockist

- Cr-Mo WP11 Short Stub End Exporter

- ANSI B16.9 Alloy Steel WP11 Stub End

- ASME SA234 CrMo WP11 Stub Ends Manufacturer

- Alloy Steel WP11 Stub Ends Supplier

- ASTM A234 Alloy Steel WP11 Stub Ends

- Alloy Steel A234 WP11 Long Stub Ends

Lateral Tee

- Alloy Steel WP11 Lateral Tees Supplier

- ASME SA234 Alloy Steel WP11 Lateral Tees

- Cr-Mo WP11 Welded Lateral Tee Stockist

- ANSI B16.9 Alloy Steel WP11 Lateral Tee Manufacturer

- ASTM A234 Alloy Steel WP11 Lateral Tee

- WP11 Chrome Moly Lateral Tee Exporter

- Alloy Steel A234 WP11 Buttweld Lateral Tee

- Alloy Steel A234 WP11 Lateral Tees

Nipple

- Alloy Steel WP11 Nipples Supplier

- CrMo A234 WP11 Welded Nipples

- ANSI B16.9 Alloy Steel WP11 Nipple

- ASME SA234 AS WP11 Nipples Manufacturer

- ASTM A234 Alloy Steel WP11 Buttweld Nipples

- CrMo WP11 Seamless Nipple Exporter

- Alloy Steel WP11 Buttweld Nipples Stockist

- Alloy Steel A234 WP11 Swage Nipples

ASTM A234 Alloy steel wp11 Pipe Fittings Chemical Composition

| Grade | C | Mn | Si | S | P | Cr | Mo |

| A234 WP11 | 0.05-0.2 | 0.3-0.8 | 0.5-1 | ≤0.030 | ≤0.030 | 1-1.5 | 1-1.5 |

alloy steel wp11 Seamless Fittings Mechanical Properties

| Grade | Tensile Strength (Mpa) | Yield Strength (Mpa) | Elongation % |

| A234 WP11 | 415 – 585 | ≥205 | ≥20 |

Other Types alloy steel wp11 Pipe Fittings

- Alloy Steel WP11 1D / 3D / 5D Elbow

- Suppliers of Chrome Moly WP11 End Pipe Cap

- Alloy Steel A234 WP11 Butt weld Equal Tee

- Alloy Steel A234 WP11 LR Elbow Supplier

- Alloy Steel WP11 Buttweld 90° Elbow Stock

- Alloy Steel WP11 180 Deg Elbow in Mumbai

- Grade WP11 Chrome Moly Fabricated Tee

- A234 WP11 Alloy Steel Concentric Reducer Supplier in India

- Alloy Steel WP11 Short Radius Elbows Manufacturer

- Sch 80 Chrome Moly WP11 Pipe Fittings

- A234 WP11 CrMo Short Radius Elbow Dealer in India

- Chrome Moly WP11 Pipe Fittings Dimensions

- Chromium-Molybdenum Steel WP11 Swage Nipple Fittings

- WP11 Alloy Steel 180° LR Return Bend

- ASTM A234 Cr-Mo WP11 Two Joint Pipe Fittings

- Alloy Steel WP11 45 Degree Elbow Manufacturer

- Alloy Steel WP11 Weldable 1.5D Elbow

- Chrome Moly A234 WP11 Lap Joint Stub Ends

- Alloy Steel A234 WP11 Eccentric Reducer Exporters

- Alloy Steel WP11 Equal Cross Stockholder

- Alloy Steel WP11 U Shape Bend Stockist in Mumbai

- Alloy Steel A234 WP11 90° SR Elbow

Alloy Steel WP11 Welded Fittings Application Industries

Searches related to Alloy Steel WP11 Pipe Fittings

We Export Alloy steel wp11 Pipe Fittings to Following Destinations

MATERIALS

PRODUCTS