Alloy Steel A182 F9 Flanges SUPPLIER

Steel Sales Co. is a renowned distributor of alloy steel products, refined and manufactured in pristine quality, such as the alloy steel A182 F9 flanges. The trust we have garnered through thousands of clientele has only determined us to strive forward in producing superior quality products and enabled us to adopt innovations in our methods of fabrication, handling, and packaging as well, all towards ensuring that the product remains of higher quality.

ASTM A182 F9 FLANGES, ALLOY STEEL F9 INDUSTRIAL FLANGES AT BEST PRICE, 1.7386 FLANGES, CHROME MOLY F9 FLANGE, GRADE F9 ALLOY STEEL FLANGES EXPORTER, ANSI B16.5 ALLOY STEEL F9 FLANGES, CRMO K90941 FLANGES, ASTM A182 GRADE F9 ALLOY STEEL PIPE FLANGES EXPORTER, ALLOY STEEL F9 FLANGES SUPPLIERS, ASTM A182 GR F9 FLANGE, ASME SA182 ALLOY STEEL F9 FLANGES SUPPLIER IN INDIA.

- What is Alloy Steel A182 F9 Flanges

- Standard Specification For Alloy Steel A182 F9 Flanges

- Alloy Steel A182 F9 Flanges Equivalent Grades

- Types of Alloy Steel A182 F9 Flanges

- Alloy Steel A182 F9 Flange Chemical Composition

- Mechanical Properties of Alloy Steel A182 F9 Flanges

- Other Types of Alloy Steel A182 F9 Flanges Ready Stock

- Alloy Steel A182 F9 Flanges Applications

- Searches Related to Alloy Steel A182 F9 Flanges

- Export Destinations for Alloy Steel A182 F9 Flanges

Composed primarily of chromium and molybdenum, the alloy steel A182 F9 flanges comprise majorly of the above-mentioned elements and are hence, also called chrome-moly alloys. The unique characteristics of the flanges are due to this increment in the chromium and molybdenum content which adds to the hardening and corrosion resistance of the flanges. There are other elements present in the flanges apart from those mentioned above and these are silicon, sulfur, phosphorus, etc. The additional elements, including chromium and molybdenum, not only stabilize the iron-based alloy but also bestow it with properties it is widely used for. Silicon for instance improves the resistance of the flanges against oxidation, which comes in handy when operating in oxidizing environments.

A182 GR F9 THREADED / SCREWED FLANGES, ALLOY STEEL ASTM A182 F9 LAP JOINT FLANGES, ASTM A182 GR F9 RING TYPE JOINT (RTJ) FLANGES, CR-MO F9 FLAT FACE (FF) FLANGES, ASTM A182 GRADE F9 SPECTACLE BLIND FLANGE STOCKIST, ASTM A182 F9 SORF FLANGES, ASTM A182 F9 FORGED FLANGES, ASME SA 182 F9 BLIND FLANGE, AS F9 WELD NECK FLANGES, ALLOY STEEL A182 F9 SLIP ON FLANGES, ASTM A182 ALLOY STEEL F9 SOCKET WELD FLANGES, ASTM A182 ALLOY STEEL F9 RAISED FACE (RF) FLANGES, ASTM A182 F9 BLRF FLANGE, AS ASTM A182 F9 FLAT FACE FLANGES, ASTM A182 F9 FLANGES MANUFACTURER IN MUMBAI.

The most important function of the flanges is to connect the different components and strengthen the system as a whole. To stabilize the entire system, the alloy steel flanges of the grade A182 F9 itself are equipped with strength and toughness. This tensile strength of the flanges enables it to withstand any form of mechanical strain as well as the internal pressure changes it might have to face when connecting different pipes together. The stability displayed by the flanges is not only because of its toughness but can be attributed to the resistance it expertly exhibits against both heat and corrosion. When it comes to corrosion resistance, the F9 flanges are resistant to a number of diverse corrosive agents, be they liquids or gases. Elevated temperatures are also tackled by the heat resistance and thermal stability displayed by the flanges.

The diverse properties coupled with its durability and simplicity has rendered it with applications in vivid industries, a few being, the chemical industry, marine applications, petrochemical, fertilizer industry, the dairy industry, food processing, construction, oil refineries, pulp and paper industry, sugar factories, etc.

Quality assurance is crucial step post-production and one which requires suitable tests to be conducted on the products for the determination of their quality and stability. We strictly carry out tests on every product we manufacture on a regular basis, with inspections organized periodically.

Standard Specification

- Specifications

- Size

- Dimensions

- Standard

- Pressure Class / Rating

- Flange Connect Type/ Face Type

- Specialized manufacturer of

Alloy Steel F9 flanges Equivalent Grades

| STANDARD | UNS | WERKSTOFF NR. | Trade Name |

| Alloy Steel F9 | K90941 | 1.7386 | 9Cr-1Mo |

Types of Alloy Steel A182 F9 Flanges

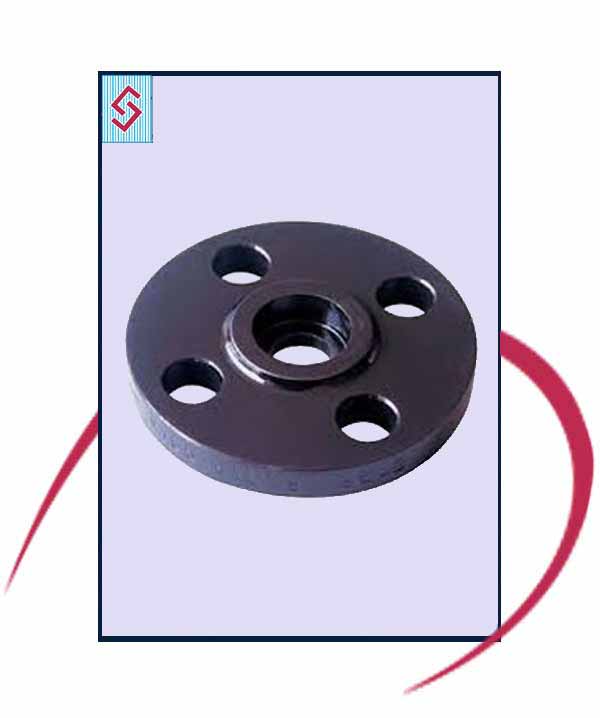

Slip On Flanges

- ASTM A182 F9 SORF Flanges

- ASTM A182 Alloy Steel F9 Slip On Flanges Supplier

- SA 182 Gr F9 Slip On Flange

- ASTM A182 F9 Slip On Flanges Stockist

- ASTM A182 F9 Alloy Steel Raised Face Slip on Flange Exporter

- Alloy Steel F9 Slip On Flange

- ASTM A182 F9 SORTJ Flange

- ASTM A182 F9 RFSO Flanges

- ASME SA182 F9 Slip On Flanges

- Alloy Steel Gr. F9 Slip On Flanges

- Alloy Steel F9 SOFF Flanges

- Alloy Steel A182 F9 Slip On Flanges Manufacturer

Weld Neck Flanges

- CrMo A182 F9 Weld Neck Flanges

- Alloy Steel 1.7386 Weld Neck Flange

- ASME SA182 AS F9 Weld Neck Flanges

- ASTM A182 Alloy Steel F9 WNFF Flange

- Alloy Steel A182 F9 RFWN Flange

- Alloy Steel Gr. F9 Weld Neck Flanges Supplier

- Alloy Steel ASTM A182 F9 Welding Neck Flange Manufacturer

- ASTM A182 Grde F9 WNRF Flanges

- ASTM A182 F9 Weld Neck Flanges

- Chrome Moly K90941 Weld Neck Flanges Stockist

- ASME SA182 F9 Weld Neck Flanges

- ASTM A182 F9 Welding Neck Flanges

- ASTM A182 F9 Alloy Steel WNRTJ Flange

Socket Weld Flanges

- A182 Gr F9 RFSW Flanges

- ASTM A182 F9 Socket Weld Flanges

- ASTM A182 Grade F9 SW Flanges

- 1.7386 Socket Weld Flanges Stockist

- F9 CrMo Socket Weld Flange Exporter

- ASME SA182 F9 Socket Weld Flanges

- Alloy Steel F9 Socket Weld Flanges Supplier

- A182 F9 Alloy Steel Socket Weld Flange

- ASTM A182 F9 SWFF Flange

- ASTM A182 F9 SW Flanges

- Alloy Steel K90941 Socket Weld Flanges

- ASME SA 182 Chrome Moly Gr F9 Socket Weld Flange

- ASTM A182 Alloy Steel F9 SWRTJ Flanges

- ASTM A182 F9 SWRF Flanges

Blind Flanges

- ASTM A182 Grade F9 Alloy Steel BLRF Flanges

- ASTM A182 Alloy Steel F9 BLRTJ Flange

- ASTM A182 Gr F9 Alloy Steel RFBL Flanges

- UNS K90941 Blind Flanges

- ASTM A182 F9 Blind Flanges Stockist

- AS Gr. F9 Blind Flanges

- ASTM A182 F9 Blind Flange Manufacturer

- ASTM A182 F9 Raised Face Blind Flange Exporter

- Alloy Steel F9 Blind Flange

- ASTM A182 F9 Alloy Steel Blind Flanges Supplier

- ASTM A182 F9 Blind Flange

- CR-Mo 1.7386 Blind Flanges

- ASTM A182 Chrome Moly F9 BLFF Flange

Ring Type Joint Flanges

- ASTM A182 Gr F9 Ring Type Joint Flanges

- ASME SA182 F9 Ring Type Flanges

- Alloy Steel Gr F9 RTJ Flanges Manufacturer

- SA 182 Chrome Moly Gr F9 Ring Type Joint Flanges

- ASTM A182 F9 Alloy Steel Ring Type Joint Flanges Supplier

- 1.7386 Ring Type Joint Flanges

- ASTM A182 Grade F9 RTJ Flanges

- ASTM A182 F9 Alloy Steel RTJ Flanges

- Alloy Steel K90941 Ring Type Joint Flange

- ASTM A182 F9 Ring Type Flange Exporter

- ASTM A182 F9 RTJ Flanges Stockist

- ASTM A182 F9 CrMo Ring Type Joint Flanges

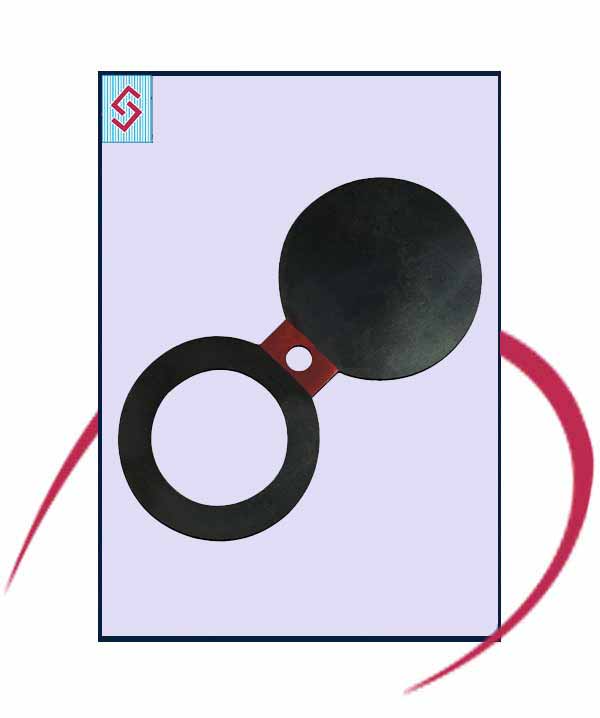

Spectacle Blind Flanges

- ASTM A182 F9 Spectacle Blind Flanges

- 1.7386 Spectacle Blind Flanges

- CrMo F9 Spectacle Blind Flanges Supplier

- ASTM A182 Gr. F9 Alloy Steel Spectacle Blind Flanges

- SA 182 F9 Spectacle Blind Flanges Stockist

- Alloy Steel Grade F9 Spectacle Blind Flanges

- Alloy Steel K90941 Spectacle Blind Flange

- ASTM A182 Alloy Steel F9 Spectacle Blind Flange Exporter

- AS ASME SA182 F9 Spectacle Blind Flanges

- Chrome Moly F9 Spectacle Blind Flange Manufacturer

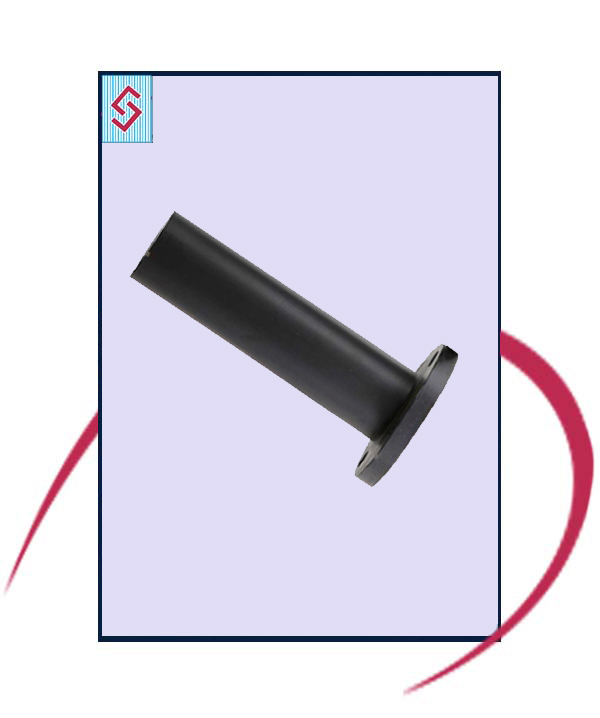

Long Weld Neck Flanges

- ASTM A182 F9 Long Weld Neck Flanges

- ASME SA182 F9 Long Weld Neck Flanges

- ASTM A182 F9 Long Welding Neck Flanges

- Alloy Steel K90941 Long Weld Neck Flange

- F9 Alloy Steel Long Weld Neck Flanges Supplier

- Alloy Steel A182 Gr. F9 Long Weld Neck Flanges

- ASTM A182 Grade F9 Long Weld Neck Flanges

- 1.7386 Long Weld Neck Flange Exporter

- F9 Long Weld Neck Flanges Stockist

- ASTM A182 F9 LWN Flanges

Lap Joint Flanges

- ASTM A182 F9 Lapped Joint Flange Exporter

- A182 F9 Lap Joint Flanges Stockist

- ASME SA182 F9 Lap Joint Flanges

- CrMo K90941 Lapped Joint Flanges

- Grade F9 Lap Joint Flanges

- ASTM A182 F9 LJ Flanges

- ASTM A182 F9 Lap Joint Flanges

- Alloy Steel F9 Lap Joint Flange

- ASTM A182 Grade F9 Alloy Steel Lap Joint Flanges Supplier

- 1.7386 Lap Joint Flanges

- AS A182 F9 Lapped Joint Flanges

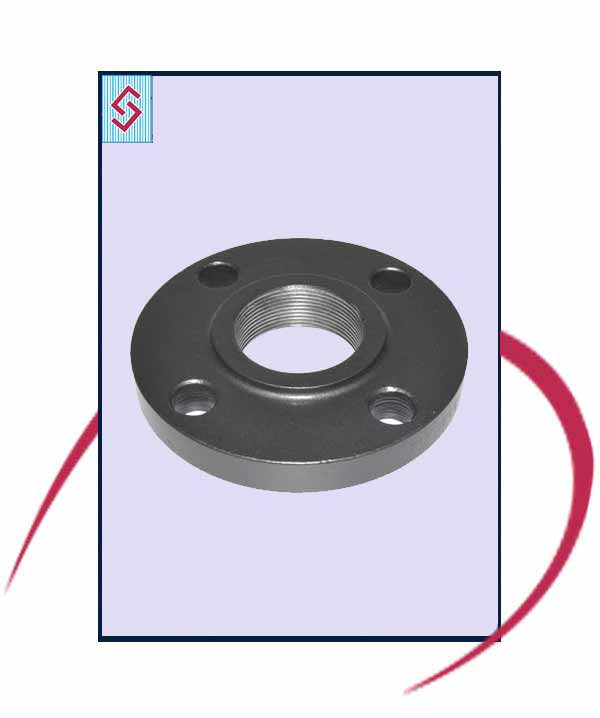

Threaded Flanges

- Chrome Moly Gr. F9 Threaded Flanges

- Alloy Steel A182 F9 Threaded Flanges

- ASTM A182 F9 Alloy Steel Threaded Flanges

- ASTM A182 Alloy Steel F9 Screwed Flanges

- ASTM A182 F9 Threaded Flanges

- ASME SA182 F9 Threaded Flanges

- 1.7386 Threaded Flanges Stockist

- Alloy Steel F9 Threaded Flange Manufacturer

- ASTM A182 F9 Screwed Flange Exporter

- ASTM A182 F9 Threaded Flanges Supplier

- Cr-Mo K90941 Screwed Flanges

Alloy Steel A182 F9 Flanges Chemical Composition

| Grade | C | Mn | Si | P | S | Cr | Mo |

| Alloy Steel F9 | 0.15 max | 0.3-0.6 | 0.5 – 1 | 0.03 | 0.03 | 8 – 10 | 0.9 – 1.1 |

A182 SA 182 Alloy Steel F9 Flanges Mechanical Properties

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min |

| Alloy Steel F9 | 380 | 585 | 20 |

Other Types Alloy Steel A182 F9 Flanges

- Alloy Steel ASTM A182 F9 Flanges Supplier in India

- Alloy Steel F9 Nipo Flanges Exporters

- ASTM A182 Grade F9 Spades Ring Spacers Flanges

- ASME SA 182 Alloy Steel F9 SWRF Flanges

- ASTM A182 F9 Class 300 Flat Flange in India

- Alloy Steel F9 Flanges Pressure Rating

- ASME B16.5 F9 Long Weld Neck Flanges in India

- ASTM A182 F9 Alloy Steel Tongue & Groove Flanges

- Alloy Steel A182 F9 Screwed Flanges Manufacturer in India

- Alloy Steel F9 Loose Flange Stockholder in Mumbai

- ASTM A182 F9 Plate Flanges Manufacturer

- Alloy Steel F9 High Hub Blinds Flanges

- Alloy Steel K90941 Orifice Flanges Manufacturer

- ASTM A182 F9 Reducing Flanges Supplier in India

- ASME SA182 F9 AS Expander Flanges Supplier

- ANSI B16.5 Alloy Steel F9 Pipe Flange

- ASTM A182 F9 Alloy Steel SORF Flanges Exporter

- ASTM A182 Gr. F9 Loose Flanges Supplier in Mumbai

- ASTM A182 F9 Expander Flanges at Best Price

- ASTM A182 Alloy Steel F9 Nipo Flanges

- ASTM A182 F9 Alloy Steel Flanges Din Standard

- ASTM A182 Alloy Steel F9 RTJ Flanges

ASTM A182 F9 Alloy Steel Flanges Application Industries

Searches related to Alloy Steel A182 F9 Flanges

We Export Alloy Steel A182 F9 Flanges to Following Destinations

Angola, Serbia, Jordan, Indonesia, Iran, United States, Qatar, Iran, South Korea, Thailand, Mongolia, Russia, Philippines, Ukraine, Bolivia, Chile, Belarus, Egypt, Norway, Chile, Ghana, Morocco, Argentina, Kenya, Bahrain, Netherlands, Bhutan, Trinidad & Tobago, Sri Lanka, Kuwait, Tunisia, Poland, Ecuador, Yemen, Venezuela, Turkey, Mexico, Azerbaijan, South Africa, Portugal, Italy, United Arab Emirates, Romania, Hong Kong, Switzerland, Australia, Costa Rica, Taiwan, Afghanistan, Bulgaria, Israel, Gabon, Austria, Lebanon, China, Singapore, New Zealand, Spain, Croatia, France, Brazil, Kazakhstan, Japan, Colombia, Pakistan, Saudi Arabia, Peru, Greece, Algeria, Libya, United Kingdom, Slovakia, Sweden, Mexico, Vietnam, Denmark, Hungary, Estonia, Malaysia, Poland, Czech Republic, Lithuania, Nigeria, Nigeria, Iraq, Oman, Bangladesh, Finland, Belgium, Canada.

Manama, Sydney, Melbourne, Chandigarh, Dammam, Lagos, Surat, Kolkata, Nagpur, Al Jubail, Ahvaz, Kuwait City, Istanbul, Ahmedabad, Indore, Courbevoie, Ernakulam, Riyadh, Lahore, Colombo, Aberdeen, Mumbai, New York, Secunderabad, Muscat, Jeddah, Thane, Baroda, Ludhiana, Ankara, Calgary, Brisbane, Dubai, Jamshedpur, Abu Dhabi, Visakhapatnam, Toronto, Haryana, Coimbatore, Montreal, Kuala Lumpur, Kanpur, Thiruvananthapuram, Edmonton, Dallas, Caracas, Milan, Granada, Algiers, Jakarta, Ranchi, Pune, Madrid, Al Khobar, Navi Mumbai, Rio de Janeiro, Port-of-Spain, Hanoi, Gimhae-si, Noida, Vadodara, Busan, Chennai, Doha, Bengaluru, Perth, Chiyoda, Bangkok, Sharjah, Pimpri-Chinchwad, Hyderabad, La Victoria, Los Angeles, Petaling Jaya, Cairo, New Delhi, Bhopal, Seoul, Houston, Faridabad, Rajkot, Ho Chi Minh City, Bogota, Santiago, Tehran, Ulsan, Howrah, Vung Tau, Jaipur, Atyrau, Geoje-si, Gurgaon, Nashik.

MATERIALS

PRODUCTS