Express Delivery

We understand the urgency of product requirement for Oil & Gas Industry & industrial breakdowns at various situations attenuating the project performance.

Our Certifications

Steel Sales and Co is a highly regarded and trusted name in terms of manufacturing alloy steel A234 WP5 buttweld pipe fittings of a pure standard and supplying them throughout the world. Our factories are loaded with advanced world-class modern machinery that is constantly maintained and upgraded to the latest innovations. The raw materials we use are procured from authentic sources and are tested for their purity before the production begins.

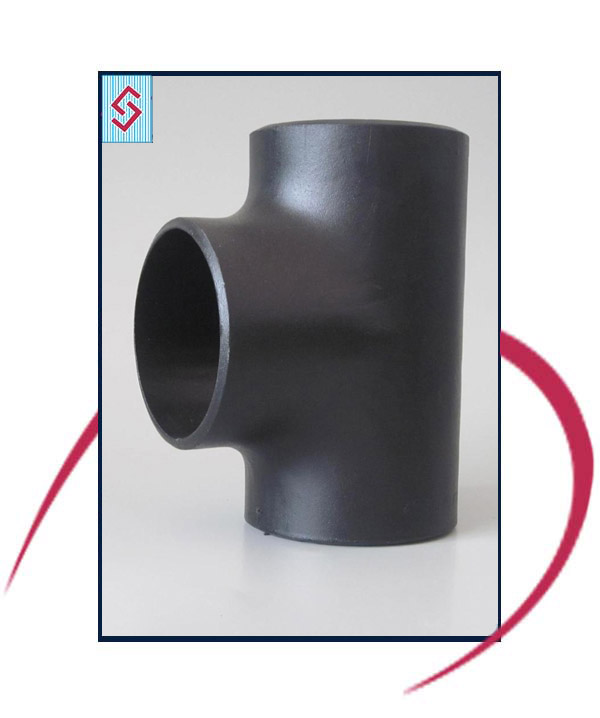

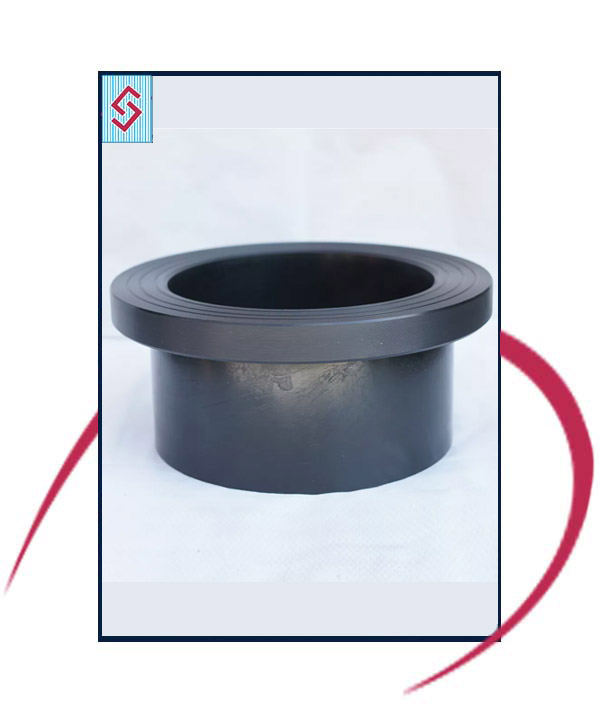

The alloy steel A234 WP5 buttweld pipe fittings have a characteristic reduction in the fraction of chromium until 4-6% and the absence of nickel. The absence of nickel reduces the chances of the fittings suffering from corrosion and succumbing to rust. Chromium plays an active role in providing the buttweld fittings with additional corrosion resistance attributes while also increasing their hardness and strength. Other elements present in the fittings are sulfur, manganese, silicon, carbon, phosphorus, and molybdenum. The addition of molybdenum coupled with the presence of chromium makes the A234 WP5 fittings a chrome-moly alloy. The role of molybdenum in the alloy is to boost its heat resistance and thermal conductivity at elevated temperatures, protecting the alloy from stress resistance.

The superior tensile strength attributed to alloy steel spigot fittings is a very useful trait for the efficient functioning of the alloy in strenuous situations. The tensile strength and yield strength grant the fittings with toughness and increased durability. The alloy grade in consideration has been known to tackle elevated temperatures while retaining its stability and efficacy. Higher temperatures give way to physical and chemical damage in many alloys, but due to the thermal conductivity of the pipe fittings, they have the potential to remain unaffected by it while continuing to work effectively. Corrosion is another problem that usually hinders the operation in various industries and which is defended by the pipe fittings, making them ideal for usage in the presence of corrosive agents.

The application which makes use of the diverse traits contributed by the alloy steel A234 WP5 socket weld fittings are marine industry, refineries, petrochemical, valves, pumps, gas processing, etc.

We firmly believe that the quality of the products we deliver should be able to fulfill all the demands and expectations of our clientele and to ensure that it is truly fulfilled, we conduct a number of tests on every product we manufacture along with periodic inspections and certifications.

Standard Specification

| Grade | C | Mn | Si | S | P | Cr | Mo |

| A234 WP5 | ≤0.15 | ≤0.6 | ≤0.5 | ≤0.04 | ≤0.03 | 4-6 | 0.44-0.65 |

| Grade | Tensile Strength (Mpa) | Yield Strength (Mpa) | Elongation % |

| A234 WP5 | 415 – 585 | ≥205 | ≥20 |

MATERIALS

PRODUCTS

Express Delivery

We understand the urgency of product requirement for Oil & Gas Industry & industrial breakdowns at various situations attenuating the project performance.

Our Certifications