Express Delivery

We understand the urgency of product requirement for Oil & Gas Industry & industrial breakdowns at various situations attenuating the project performance.

Our Certifications

Steel Sales Co belongs is a respected and honored firm expertising in supplying and producing products like the alloy steel A234 WP1 buttweld pipe fittings made from high standard raw materials and the latest technological machinery. With our quality matching the customer expectations, the cost at which we distribute our products is reasonable and affordable.

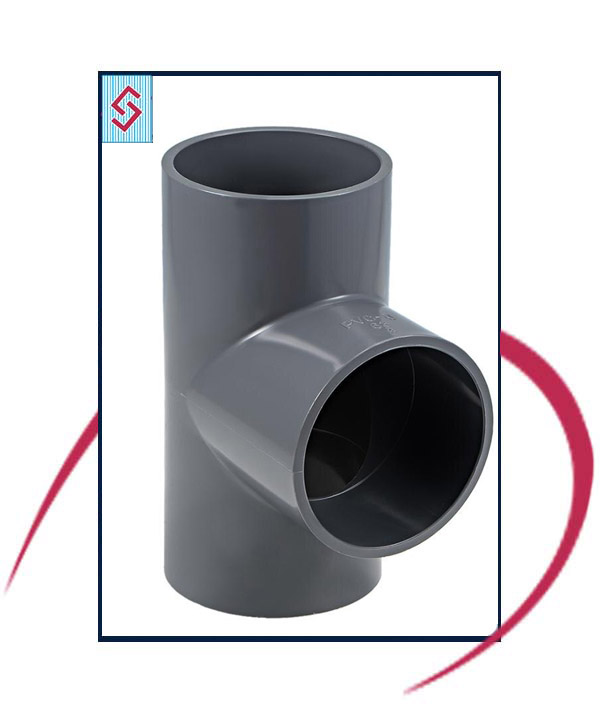

Alloy Steel A234 WP1 buttweld pipe fittings are chrome molly alloys and hence, consist of chromium and molybdenum playing major roles in their chemical composition. Pipe fittings are specific parts used in pipings that are responsible for changing the direction of flow and connecting the different pipes together. Therefore, buttweld fittings are an important part of piping solutions. The grade of fittings in consideration are known for the incorporation of molybdenum in their chemical makeup. Introduction of molybdenum grants the alloy with corrosion resistance and heat resistance against elevated temperatures. Other elements added to the alloy are manganese, phosphorus, carbon, silicon, and sulfur. Out of which manganese bestows the fittings with strength and hardness as well as resistance to corrosion.

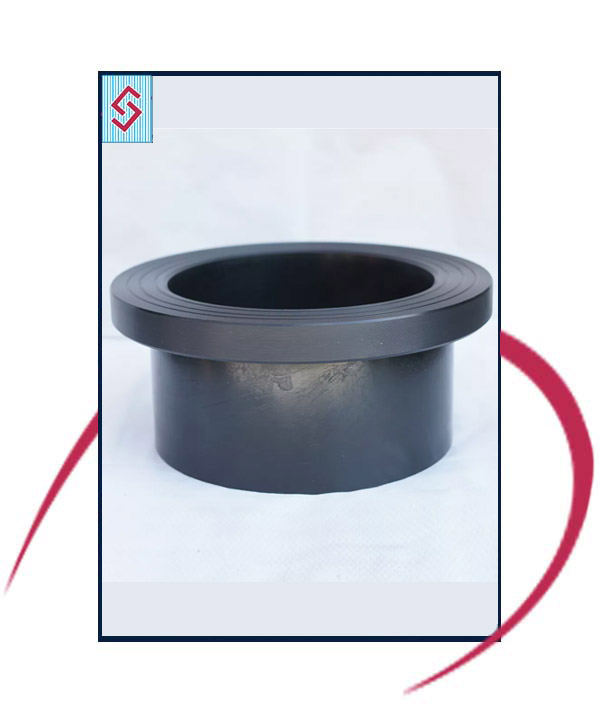

Alloy Steel A234 WP1 flanged fittings compose themselves and retain their functionality through a wide spectrum of temperatures, including elevated temperatures as well as cold conditions. The thermal conductivity of the socket weld is impressive and enables it to operate in temperatures far exceeding normal temperatures without falling prey to stress corrosion or any form of damage caused by heat. Pipes are responsible for containing liquids or gases and many of them turn out to be corrosive, thus, the corrosion resistance property of the socket weld fittings belonging to the grade in discussion defends them against corrosion especially crystalline corrosion caused by corrosive liquids and gases. The weldability and machinability of the pipe fittings are also appreciable.

The industries currently utilizing the diverse and useful properties displayed by the alloy steel A234 WP1 buttweld pipe fittings include the chemical industry, power plants, sugar industry, petrochemical, water supply systems, shipbuilding, metallurgy, food processing, fertilizer industry, etc.

With quality as our number one priority, we make sure that every product we manufacture is tested thoroughly for its quality and properties before we ship them to our clientele. Periodic inspections are also an important routine post and pre-production.

Standard Specification

| C, % | Mn, % | P, % | S, % | Si, % | Mo, % |

| 0.28 max | 0.30- 0.90 | 0.045 max | 0.045 max> | 0.10- 0.50 | 0.044-0.65 max |

| Tensile Strength , MPa | Yield Strength, MPa | Elongation, % | Hardness, HB |

| 220 min | 415 min | 20 min | 121-174 |

MATERIALS

PRODUCTS

Express Delivery

We understand the urgency of product requirement for Oil & Gas Industry & industrial breakdowns at various situations attenuating the project performance.

Our Certifications