Express Delivery

We understand the urgency of product requirement for Oil & Gas Industry & industrial breakdowns at various situations attenuating the project performance.

Our Certifications

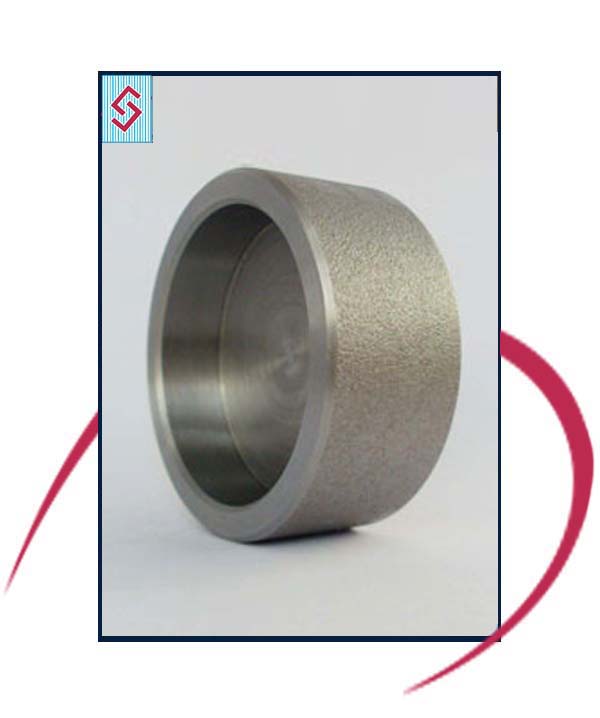

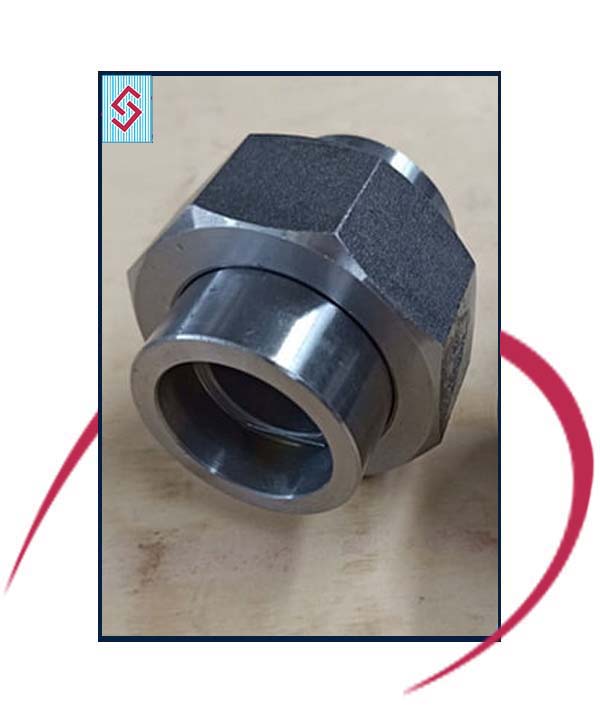

Steel Sales Co is a Mumbai-based manufacturer, exporter, and even a distributor of the Hastelloy C276 Forged Fittings. We are also involved in the stocking of these Hastelloy C276 Forged Fittings. We are completely fine with customizing these Hastelloy C276 products according to the requisitions of our patrons. We, at Steel Sales Co, aim to formulate these Hastelloy C276 Forged Fittings with the best quality possible in accordance to the national and international standards such as ASME, ASTM, DIN, etc.

These Hastelloy C276 Forged Fittings are an amalgamation of several elements embellished with rich qualities but the most prominent elements like nickel, chromium, and molybdenum are combined to provide a strong base to the Hastelloy C276 category. This chemical composition of the Hastelloy C276 category makes it a superalloy. There is an extra element added to the mixture of the Hastelloy C276 and that is tungsten. These elements, altogether provide the Hastelloy C276 Forged Fittings with a group of extremely great mechanical properties, beginning from the features as simple as excellent resistance against corrosion caused in severe atmospheres, resistance against the pitting and crevice corrosion occurring in the reducing atmospheres to features as complex as providing resistance to the act of oxidation. Since the carbon concentration in the Hastelloy C276 Forged Fittings is lower, it eventually reduces the carbide precipitation while the welding processes. The nickel element present in the Hastelloy C276 Forged Fittings are resistive to the development of the grain boundary precipitates in the welded and heat-treated areas. The Hastelloy C276 category is also resistant to an array of harsh solutions of oxidizing salts like chlorides in their cupric and ferric forms. All these mechanical properties are truly helpful when these Hastelloy C276 products are in the welded condition. Strangely, the Hastelloy C276 category is one of the very few alloys that can bear the corrosive effects pertaining to the wet chlorine gas, chlorine dioxide, and hypochlorite.

There are multiple areas where these Hastelloy C276 Forged Fittings are applied, and some of those applications are waste management, pharmaceutical industry, paper and pulp industry, sour gas wells, flue gas desulfurization, heat exchangers, reaction and pressure vessels, ducts, dampers, and scrubbers.

Other Hastelloy Forged Fittings

Standard Specification

| STANDARD | WERKSTOFF NR. | UNS | JIS | GOST | EN | OR |

| Hastelloy C276 | 2.4819 | N10276 | NW 0276 | ХН65МВУ | NiMo16Cr15W | ЭП760 |

| Grade | C | Mn | Si | S | Co | Ni | Cr | Fe | Mo | P |

| C276 | 0.010 max | 1.00 max | 0.08 max | 0.03 max | 2.50 max | 50.99 min* | 14.50 – 16.50 | 4.00 – 7.00 | 15.00 – 17.00 | 0.04 max |

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Hastelloy C276 | 8.89 g/cm3 | 1370 °C (2500 °F) | Psi – 1,15,000 , MPa – 790 | Psi – 52,000 , MPa – 355 | 40 % |

MATERIALS

PRODUCTS

Express Delivery

We understand the urgency of product requirement for Oil & Gas Industry & industrial breakdowns at various situations attenuating the project performance.

Our Certifications