Express Delivery

We understand the urgency of product requirement for Oil & Gas Industry & industrial breakdowns at various situations attenuating the project performance.

Our Certifications

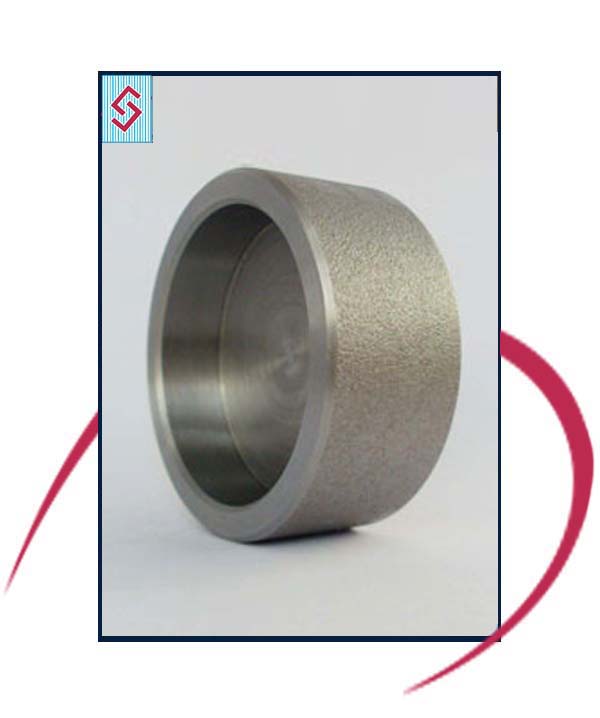

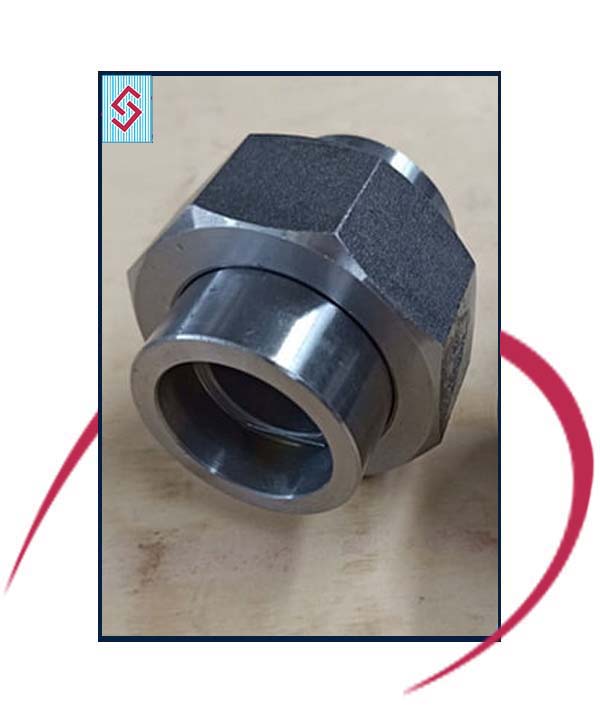

Steel Sales Co is a manufacturer and exporter of Nickel 201 Forged Fittings, situated in Mumbai. We are indulged in the stocking of these Nickel 201 Forged Fittings. We are known well in the steel and iron industry for our service in distributing the Nickel alloy products engineered by multinational steel companies.

Considerably a lot of these Nickel 201 Forged Fittings are used for purposes related to commercial work. Thus the Nickel alloy formed products are used to be applied in the wrought structures. This Nickel 201 category of the nickel alloys has exactly similar mechanical properties to that of the Nickel 200 category. The only alteration between the Nickel 200 category and the Nickel 201 category is that the latter has a lower concentration of carbon elements. This is done so, in order to prevent any embrittling effect of the Intergranular carbon that rises while the heat treatment is performed at high temperatures on these Nickel 201 Forged Fittings.

These Nickel 201 Forged Fittings are installed with the resisting capacity towards a few moderately strong acids and almost all alkalis. These Nickel 201 Forged Fittings contain a resistance against the dry gases at neutral or room temperatures. These are also resistant to the acids with a mineral base at the temperature and the dilution of the solution. These Nickel alloys exhibit an amazing amount of thermal conduction throughout their product range and hence, even these Nickel 201 Forged Fittings possess good thermal conductivity. After the annealing of the Nickel 201 Forged Fittings, the already good tensile strength enhances even further and the yielding quality also turns out to be improved.

These Nickel 201 Forged Fittings are devised and operated in ways that are quite complex as their applications require a chemically and mechanically strong and stable structure to provide the best results. Hence, some of the many areas where these Nickel 2101 Forged Fittings are fabricated are caustic environments, combustion boats, electric components, piping systems, underground water management, and vales. The industries that involve these Nickel 201 Forged Fittings are observed to be used in the Oil and Gas Refineries, Food Processing Factories, and all the other Chemical and Petrochemical factories.

Standard Specification

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Nickel 201 | 2.4068 | N02201 | NW 2201 | NA 12 | НП-2 | – | LC-Ni 99 |

| Grade | C | Mn | Si | S | Cu | Fe | Ni |

| Nickel 201 | 0.02 max | 0.35 max | 0.35 max | 0.01 max | 0.25 max | 0.40 max | 99.0 min |

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Nickel 201 | 8.9 g/cm3 | 1446 °C (2635 °F) | Psi – 67000 , MPa – 462 | Psi – 21500 , MPa – 148 | 45 % |

MATERIALS

PRODUCTS

Express Delivery

We understand the urgency of product requirement for Oil & Gas Industry & industrial breakdowns at various situations attenuating the project performance.

Our Certifications