Express Delivery

We understand the urgency of product requirement for Oil & Gas Industry & industrial breakdowns at various situations attenuating the project performance.

Our Certifications

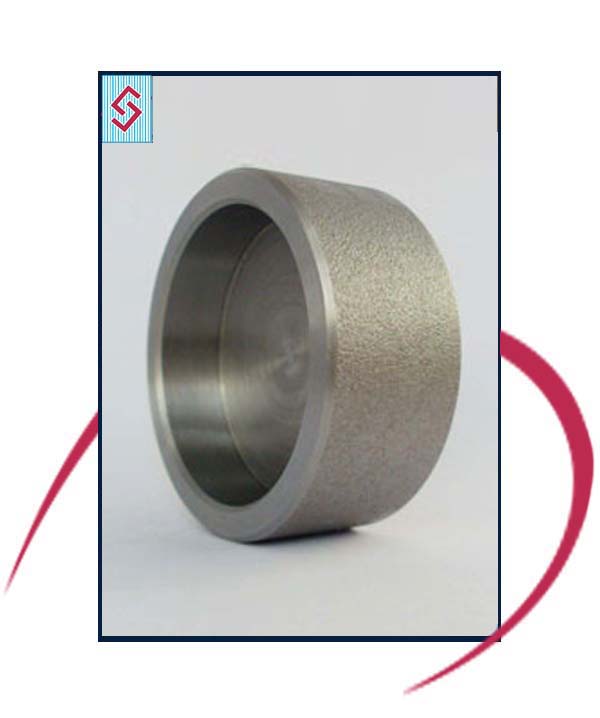

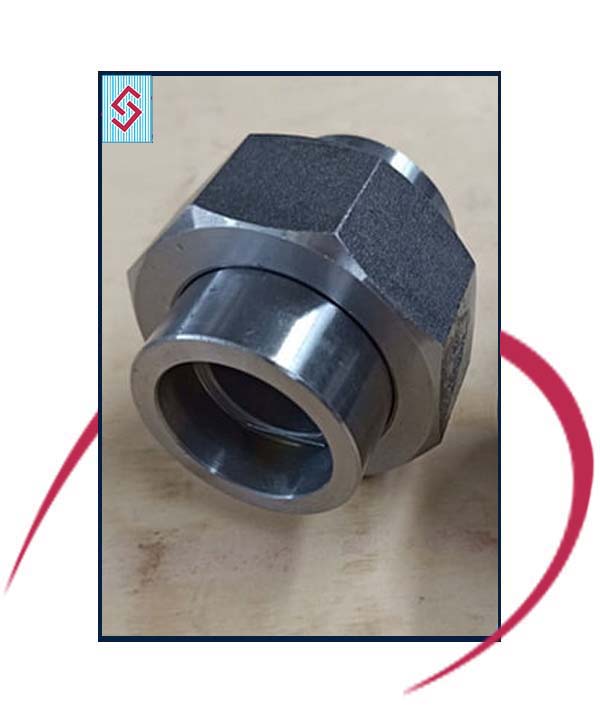

Steel Sales Co. is a total elucidation for the Inconel 617 Forged Fittings as we not only manufacture and supply but also export, stock and even distribute the Inconel 617 Forged Fittings and all other steel products.

The Inconel 617 category is a sturdy mixture of strong alloys altogether. The final chemical solution of the Inconel 617 Forged Fittings consist of the finest elements combined together which provides the Inconel 617 category with a collection of unbeatable chemical properties and its products like the forged fittings, mechanical properties that cannot fail any time sooner. The Inconel 617 Forged Fittings exhibit a great resistance against the act of oxidation.

They also are assisted with an array of corrosive media. The alloys with a base of iron are worked upon with certain basic machining, a similar technique is used for working and machining on the Inconel 617 category to manufacture the forged fittings. Commercial cooling equipment is used for the Inconel 617 Forged Fittings. Meanwhile, the work that involves a higher value of pressure on the Fittings is performed with the help of cooling equipment that functions with water. The creep rupture potential of the welded form of the Inconel 617 Forged Fittings is alike to the wrought form of the Inconel 617 Forged Fittings. In Inconel 617 Forged Fittings, the entire process of post-welding can be avoided.

One cannot count the number of examples of the Inconel 617 Forged Fittings, let alone the total applications of the Inconel 617 Forged Fittings. Thus, some of the numerous areas where the Inconel 617 Forged Fittings are fabricated are off-shore oil drilling companies, seawater equipment, power generation, chemical equipment, petrochemical industry, pharmaceutical systems, gas processing, speciality chemicals, heat exchangers, condensers, pulp, and paper industry.

Since we value client satisfaction a lot, we provide them with proper documentation with respect to the test reports of the durability, material, and reliability of Inconel 617 Forged Fittings manufactured and fabricated by us. For this, we carry out a set of tests that completely examine the production and give as appropriate results. The tests conducted are the hydrostatic test, ultrasonic test, radiography, magnetic particle test, liquid percolation test, impact and hardness test, positive material identification test, and the tensile strength test too.

Standard Specification

| STANDARD | WERKSTOFF NR. | UNS |

| Inconel 617 | 2.4663 | N06617 |

| C | Mn | S | Si | Cr | Mo | Ni | Cu | Ti | Al | B | Co | Fe |

| 0.05-0.15 | 1.0 Max | 0.015 Max | 1.0 Max | 20.0-24.0 | 8.0-10.0 | 44.5 Min | 0.5 Max | 0.6 Max | 0.8-1.5 | 0.006 Max | 10.0-15.0 | 3.0 Max |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.1 g/cm3 | 1411 °C (2571 °F) | Psi – 80,000 , MPa – 550 | Psi – 30,000 , MPa – 205 | 30 % |

MATERIALS

PRODUCTS

Express Delivery

We understand the urgency of product requirement for Oil & Gas Industry & industrial breakdowns at various situations attenuating the project performance.

Our Certifications