Express Delivery

We understand the urgency of product requirement for Oil & Gas Industry & industrial breakdowns at various situations attenuating the project performance.

Our Certifications

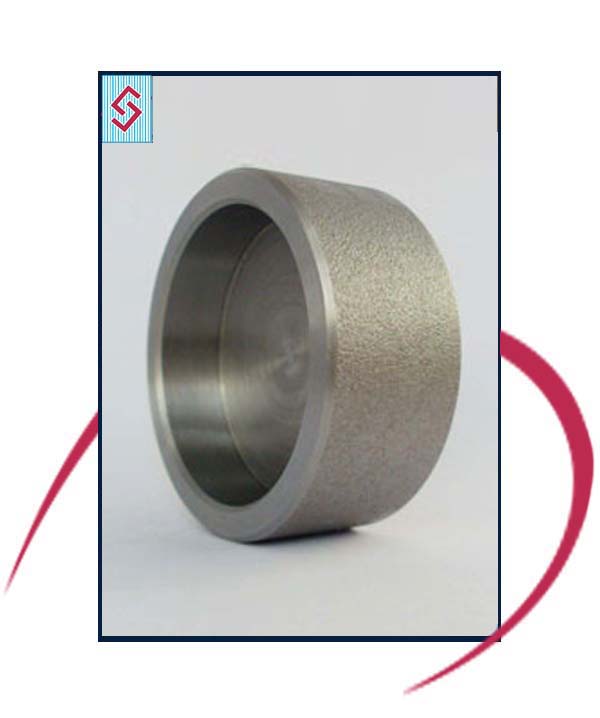

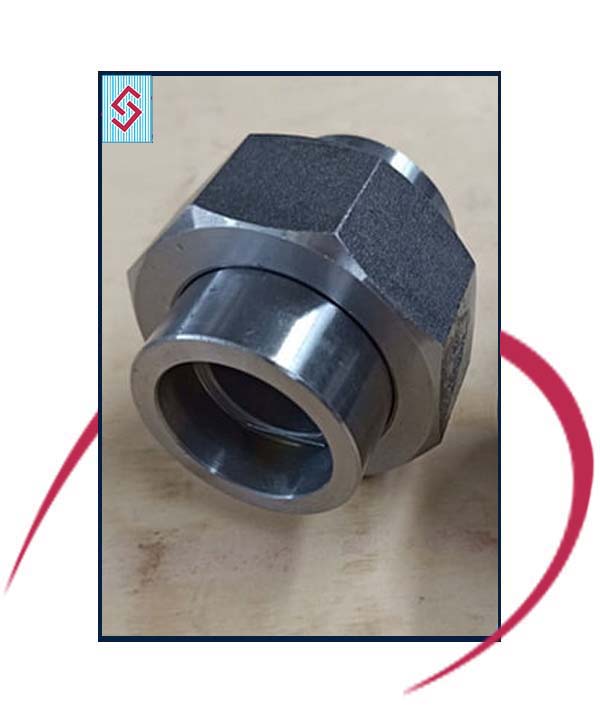

Steel sales Co is prominent manufacturer, distributor, stockiest and supplier of Stainless Steel 316 Forged Fittings based in Mumbai, India. using best quality raw material to manufacture and process products by some of the modern technologies and machineries with the help of well trained staff and experienced quality inspectors in order to maintain and improve quality of the products and material day by day.

Stainless steel 316L forged fittings are generally used for small pipe fittings.Stainless steel 316 have remarkable weldability and formability helping the material to shape it easily in any form. Stainless steel 316 has higher corrosion resistance in particularly chloride environments. This material is normally used in jet engine parts, furnace parts, pump and valve parts, pharmaceutical as well as photographic equipment, construction of exhaust manifolds, evaporators and tanks, chemical processing equipment. Stainless steel 316 has higher heat resistance which makes it more efficient in higher temperature environment and also it has more durability in chemical processing which requires higher amount of heat. Stainless steel 316 forged fittings are preferable for channelizing high acids and similar chemicals. This material can be also applicable in cutlery,cookware,chemical plants,paper mills,surgical instruments, water treatment,construction materials for large buildings, vehicles, storage tanks also in tankers that are used for food products.

Stainless steel 316H forged fittings have low carbon properties and are also commonlyknown as A4 stainless steel. This material has high level of toughness. Stainless steel 316L forged fittings are resistant to sensitization. This material is commonly used in medical devices, petrochemical industries, waste water treatment, food processing, applications near seashore and also in urban areas. This material is also considered as marine grade pipe fittings and are normally preferable for ships. Stainless steel 316L is also applicable in oxalic acids, fertilizers, dyes and many more similar processing equipment.

Stainless steel 316Ti forged fittings and stainless steel 316Ti fittings are made from stainless steel materials having higher carbon variant grade. Most preferably stainless steel 316H forged fittings are mainly applicable for higher temperature processing purposes. Stainless steel 316Ti forged fittings are made from material considered as stabilized grade of stainless steel.

Standard Specification

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 316 | 1.4401 / 1.4436 | S31600 | SUS 316 | 316S31 / 316S33 | – | Z7CND17‐11‐02 | X5CrNiMo17-12-2 / X3CrNiMo17-13-3 |

| SS 316L | 1.4404 / 1.4435 | S31603 | SUS 316L | 316S11 / 316S13 | 03Ch17N14M3 / 03Ch17N14M2 | Z3CND17‐11‐02 / Z3CND18‐14‐03 | X2CrNiMo17-12-2 / X2CrNiMo18-14-3 |

| SS 316H | 1.4919 | S31609 | – | – | – | – | – |

| SS 316Ti | 1.4571 | S31635 | SUS 316Ti | 320S31 | 08Ch17N13M2T | Z6CNDT17‐123 | X6CrNiMoTi17-12-2 |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Fe | N |

| SS 316 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 16.00 – 18.00 | 2.00 – 3.00 | 11.00 – 14.00 | 67.845 min | – |

| SS 316L | 0.035 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 16.00 – 18.00 | 2.00 – 3.00 | 10.00 – 14.00 | – | 68.89 min |

| SS 316H | 0.10 max | 2.0 max | 0.75 max | 0.045 max | 0.030 max | 16.00 – 18.00 | 2.00 – 3.00 | 10.00 – 14.00 | – | 68.89 min |

| SS 316Ti | 0.08 max | 2.0 max | 0.75 max | 0.045 max | 0.030 max | 16.00 – 18.00 | 2.00 – 3.00 | 10.00 – 14.00 | – | 68.395 min |

| Grade | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 316/316L/316H | 8.0 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

| 316Ti | 8.0 g/cm3 | 1399 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

MATERIALS

PRODUCTS

Express Delivery

We understand the urgency of product requirement for Oil & Gas Industry & industrial breakdowns at various situations attenuating the project performance.

Our Certifications