Express Delivery

We understand the urgency of product requirement for Oil & Gas Industry & industrial breakdowns at various situations attenuating the project performance.

Our Certifications

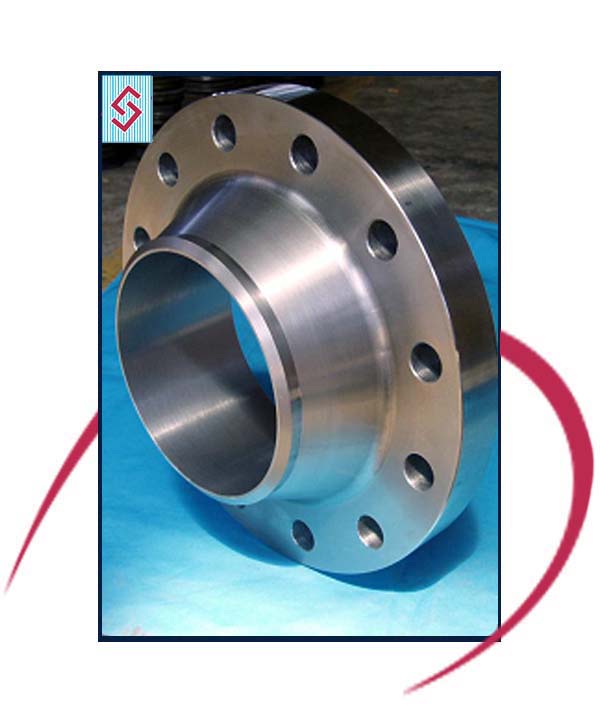

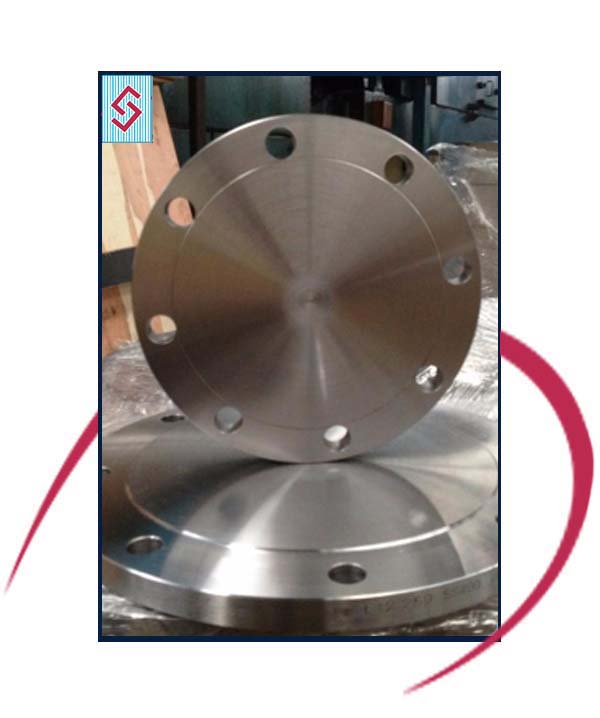

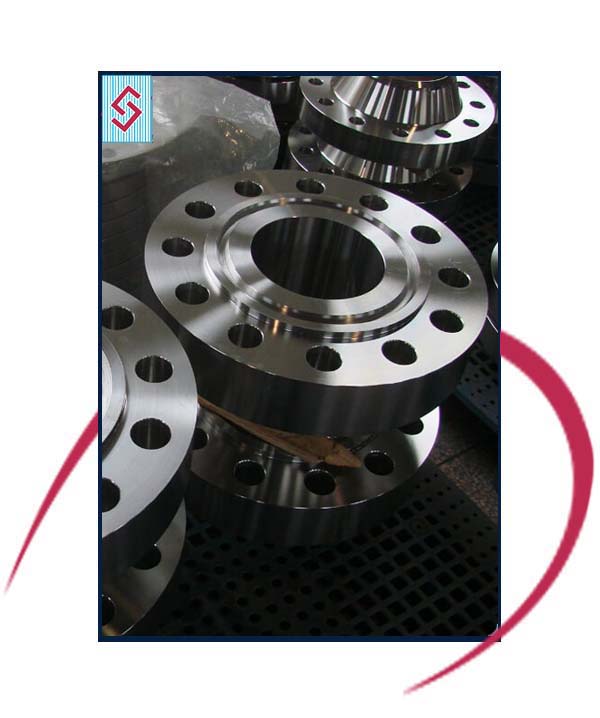

Steel Sales Co is one of the renowned Mumbai-based manufacturers and dealers of the Stainless Steel 316 Flanges. We are known well in the iron and steel industry for our exportation of these high-quality Stainless Steel 316H Flanges and many other stainless steel products too. We are also recognized well as the stockists of these Stainless Steel 316L Flanges. We aspire to be the best steel firm in the city for which our vision is to provide our clients with only the ace class of material and durability in the products that we supply.

The Stainless Steel 316H Flanges, engineered and operated by us, contain the classic amalgamation of the richest chemical elements available to formulate the Stainless Steel 316 grade. These SS 316L Flanges are a collection of the austenitic alloys of stainless steel with an addition to their basic chemical composition, which is the addition of the molybdenum element. In the chemical composition of the SS 316Ti Flanges, the content of the nickel element is moderately higher in order to imitate the SS 304 grade and provide overall corrosion resistance against the general corrosive conditions. These SS 316 Flanges also display a better amount of pitting and crevice resistance when in chloride atmospheric conditions. The SS 316L Flanges present an extraordinary mechanical property when in higher temperatures. These SS 316 Flanges possess amazing tensile strength, along with good creep and stress-rupture potency.

The Stainless Steel 316L Flanges that we fabricate are utilized by several industries to devise of even manufacture the parts and components of the machines, equipment, and tanks used in the factories which definitely belong to the various sectors of industries like the rubber and plastic machining industry, boat fittings, pump trims, and valves, textile industries, pollution management systems, Heat exchangers, condensers, pharmaceutical industry and the chemical and petrochemical processing industry, laboratory benches, tanks, and etc.

To ensure the durability, material, and reliability of these Stainless Streel 316Ti Flanges, we conduct a few tests like the hardness test, flange test, intergranular corrosion test, positive material identification test, micro test, macro test, flattening test, and many other minor chemical and mechanical tests.

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 316 | 1.4401 / 1.4436 | S31600 | SUS 316 | 316S31 / 316S33 | – | Z7CND17‐11‐02 | X5CrNiMo17-12-2 / X3CrNiMo17-13-3 |

| SS 316L | 1.4404 / 1.4435 | S31603 | SUS 316L | 316S11 / 316S13 | 03Ch17N14M3 / 03Ch17N14M2 | Z3CND17‐11‐02 / Z3CND18‐14‐03 | X2CrNiMo17-12-2 / X2CrNiMo18-14-3 |

| SS 316H | 1.4919 | S31609 | – | – | – | – | – |

| SS 316Ti | 1.4571 | S31635 | SUS 316Ti | 320S31 | 08Ch17N13M2T | Z6CNDT17‐123 | X6CrNiMoTi17-12-2 |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Fe | N |

| SS 316 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 16.00 – 18.00 | 2.00 – 3.00 | 11.00 – 14.00 | 67.845 min | – |

| SS 316L | 0.035 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 16.00 – 18.00 | 2.00 – 3.00 | 10.00 – 14.00 | – | 68.89 min |

| SS 316H | 0.10 max | 2.0 max | 0.75 max | 0.045 max | 0.030 max | 16.00 – 18.00 | 2.00 – 3.00 | 10.00 – 14.00 | – | 68.89 min |

| SS 316Ti | 0.08 max | 2.0 max | 0.75 max | 0.045 max | 0.030 max | 16.00 – 18.00 | 2.00 – 3.00 | 10.00 – 14.00 | – | 68.395 min |

| Grade | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 316/316L/316H | 8.0 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

| 316Ti | 8.0 g/cm3 | 1399 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

Express Delivery

We understand the urgency of product requirement for Oil & Gas Industry & industrial breakdowns at various situations attenuating the project performance.

Our Certifications