Express Delivery

We understand the urgency of product requirement for Oil & Gas Industry & industrial breakdowns at various situations attenuating the project performance.

Our Certifications

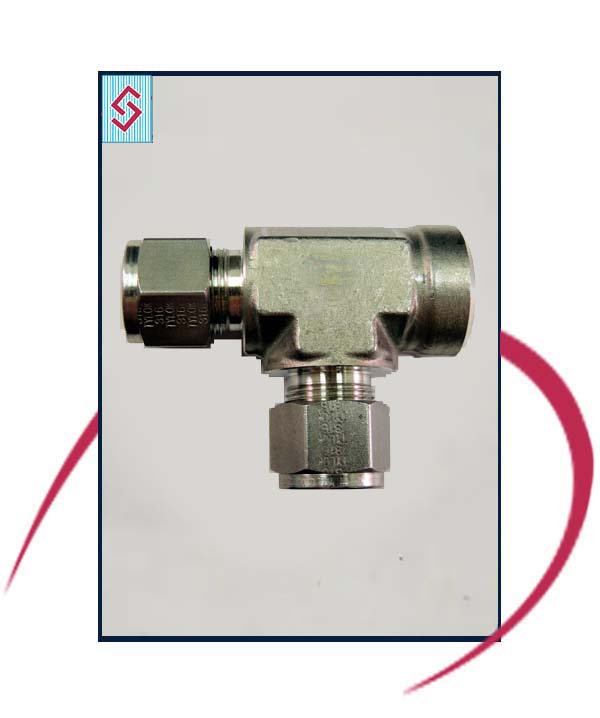

The leading company, Steel Sales Co, manufactures the vast range of products utilized broadly on a different applications. We manufacture Stainless Steel 316 Female Run Tee with different forms and variations. Our company manufactures and exports the different categories of the Stainless Steel 316 Female Run Tee to national clients and overseas clients’ applications. We manufacture the standard products, and our employees are best to develop the customized Stainless Steel 316 Female Run Tee as well. Our products are very robust and work well in any destructive application settings. We manufacture the customized and other forms of products that are advantageous for critical applications.

Stainless Steel 316 Female Run Tee products are made to connects three pipes or tubes and have an external thread at one or more sides. These threaded sides are helpful to join multiple pipes & tubes in the T section. That’s why these fittings are also known as Female Run Tee Ferrule Fittings. These Female Run Tees offer a quick, easy, safe, and reliable connection between supply and delivery lines. Moreover, Our high-grade Female Run Tee possesses leak-free connection, vibration resistance, effortless installation of various end connections & patterns.

Standard Specification

Up to 1000°F (537°C)

1/16 to 2 in.; 2 to 50 mm,

Medium-Pressure – 1/4, 3/8, 1/2, 9/16, 3/4, 1 in.; 6, 10, 12 mm

High-Pressure – 1/8 to 9/16 in.

Up to 11 000 psig (760 bar),

Medium-Pressure – Up to 20 000 psig (1378 bar)

High-Pressure – Up to 60 000 psig (4134 bar)

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 316 | 1.4401 / 1.4436 | S31600 | SUS 316 | 316S31 / 316S33 | – | Z7CND17‐11‐02 | X5CrNiMo17-12-2 / X3CrNiMo17-13-3 |

| SS 316L | 1.4404 / 1.4435 | S31603 | SUS 316L | 316S11 / 316S13 | 03Ch17N14M3 / 03Ch17N14M2 | Z3CND17‐11‐02 / Z3CND18‐14‐03 | X2CrNiMo17-12-2 / X2CrNiMo18-14-3 |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Fe |

| SS 316 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 16.00 – 18.00 | 2.00 – 3.00 | 11.00 – 14.00 | 67.845 min |

| SS 316L | 0.035 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 16.00 – 18.00 | 2.00 – 3.00 | 10.00 – 14.00 | 68.89 min |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

MATERIALS

PRODUCTS

Express Delivery

We understand the urgency of product requirement for Oil & Gas Industry & industrial breakdowns at various situations attenuating the project performance.

Our Certifications