Express Delivery

We understand the urgency of product requirement for Oil & Gas Industry & industrial breakdowns at various situations attenuating the project performance.

Our Certifications

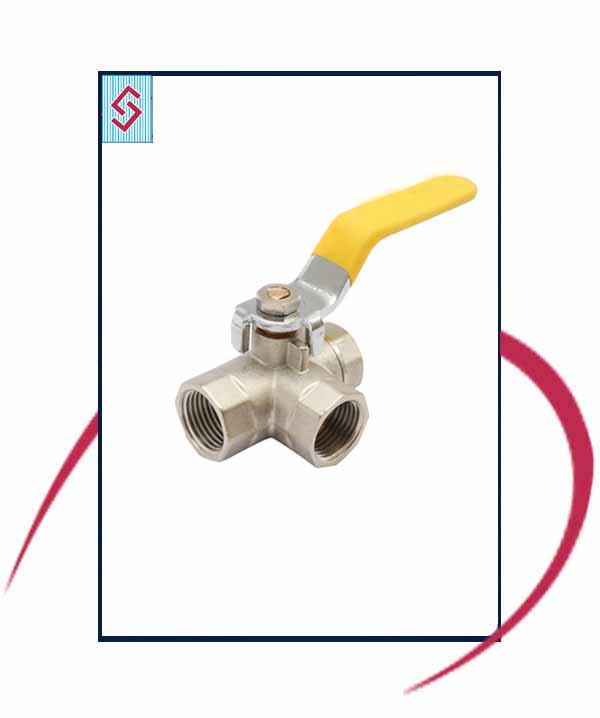

Adhering to the regulations honestly and standing by the law earnestly, we at Steel Sales Co have come a long way today. Stainless Steel 316 3 way ball valve proves to be beneficial to many uses. This material is highly accepted for other features like best formability, weldability, durability, strength, and so on. Different sizes, forms, grades, types and other specifications make these valve products highly desirable in industrial as well as domestic applications. The use of these Stainless Steel 316 3 way ball valve are widely seen in industries like petrochemical, chemical due to excellent corrosion resistance.

Stainless Steel 316 3 way ball valve has pickled accurately as they give optimum resistance capacity. Resistance against oxidation and corrosion is frequently observed in them. Stainless Steel 316 3 way ball valve has pickled accurately as they give optimum resistance can be machined in any type of variations prescribed. They have the ability to serve at elevated temperatures too. The alloy is annealed with solution content, thus increasing its yield strength. Stainless Steel 316 3 way ball valve has pickled accurately as they give optimum resistance. Their surface cracking immunity is incomparable to any austenitic stainless steel. They have enabled movement in 3 directions comfortably whether rotation or spinning. The horizontal valve on the top regulates on and off of the flow.

Standard Specification

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 316 | 1.4401 / 1.4436 | S31600 | SUS 316 | 316S31 / 316S33 | – | Z7CND17‐11‐02 | X5CrNiMo17-12-2 / X3CrNiMo17-13-3 |

| SS 316L | 1.4404 / 1.4435 | S31603 | SUS 316L | 316S11 / 316S13 | 03Ch17N14M3 / 03Ch17N14M2 | Z3CND17‐11‐02 / Z3CND18‐14‐03 | X2CrNiMo17-12-2 / X2CrNiMo18-14-3 |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Fe |

| SS 316 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 16.00 – 18.00 | 2.00 – 3.00 | 11.00 – 14.00 | 67.845 min |

| SS 316L | 0.035 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 16.00 – 18.00 | 2.00 – 3.00 | 10.00 – 14.00 | 68.89 min |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

MATERIALS

PRODUCTS

Express Delivery

We understand the urgency of product requirement for Oil & Gas Industry & industrial breakdowns at various situations attenuating the project performance.

Our Certifications