Express Delivery

We understand the urgency of product requirement for Oil & Gas Industry & industrial breakdowns at various situations attenuating the project performance.

Our Certifications

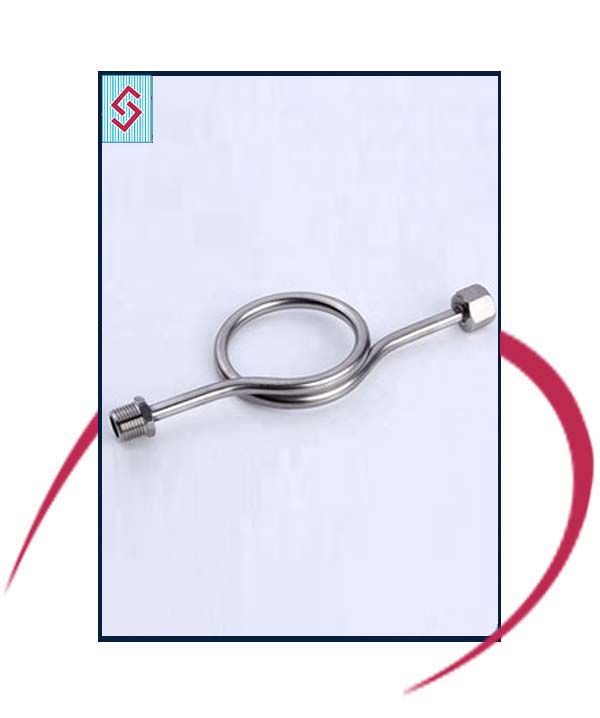

Steel Sales Co is the best leading company that offers the comprehensive range of Stainless Steel 304 Syphon tubes. In our company, tubes are accessible in an assortment of mixes according to customer necessities. So, we manufacture the customized, default and other forms of tubes per industrial applications’ needs. We always consider the quality, maintenance, verifications, and overall attributes of products. We also support quick or on-time delivery service for client’s products; by understanding the rules and guidelines of global industries, we never fail to offer high qualitative syphon tubes.

Stainless Steel and components utilized for manufacture have different attributes, such as corrosion safe, high rigidity, and yield strength. Stainless Steel 316 Syphon Tube has highlights like temperature obstruction, simple formability, appealing appearance, low upkeep, and they can use additionally recyclable. These are the unique and attractive features of our products. We manufacture them with a high-tech grade that offers the best furnishing. The pattern or shape of the syphon are curvy, so the form is based on the applications. As having the curving shape, we offer great edges that have smooth endings and finishings. They are typically associated between measure taps and pressure gauges to stay away from direct contact of live steam with applications.

Stainless Steel 316 Syphon tubes work finely with different applications; we provide excellent overall fitting properties. Then we test the products and their specifications that helps us to enhance the syphon more generally. After testing the variations and different forms of products, we proceed with the exporting and delivery phase. The composition of our Stainless Steel 316 Syphon tubes allows it to exhibit different features, including high resistance to pitting, general corrosion and crevice corrosion at chloride-containing settings. These properties help enhance the durability and performance of these tube products.

Standard Specification

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 304 | 1.4301 | S30400 | SUS 304 | 304S31 | 08Х18Н10 | Z7CN18‐09 | X5CrNi18-10 |

| SS 316 | 1.4401 / 1.4436 | S31600 | SUS 316 | 316S31 / 316S33 | – | Z7CND17-11-02 | X5CrNiMo17-12-2 / X3CrNiMo17-13-3 |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | Fe |

| SS 304 | 0.08 max | 2 max | 0.75 max | 0.045 max | 0.030 max | 18 – 20 | – | 8 – 11 | – | – |

| SS 316 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 16.00 – 18.00 | 2.00 – 3.00 | 11.00 – 14.00 | – | 67.845 min |

| Grade | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| SS 304 | 8.0 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

| SS 316 | 8.0 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

MATERIALS

PRODUCTS

Express Delivery

We understand the urgency of product requirement for Oil & Gas Industry & industrial breakdowns at various situations attenuating the project performance.

Our Certifications