Express Delivery

We understand the urgency of product requirement for Oil & Gas Industry & industrial breakdowns at various situations attenuating the project performance.

Our Certifications

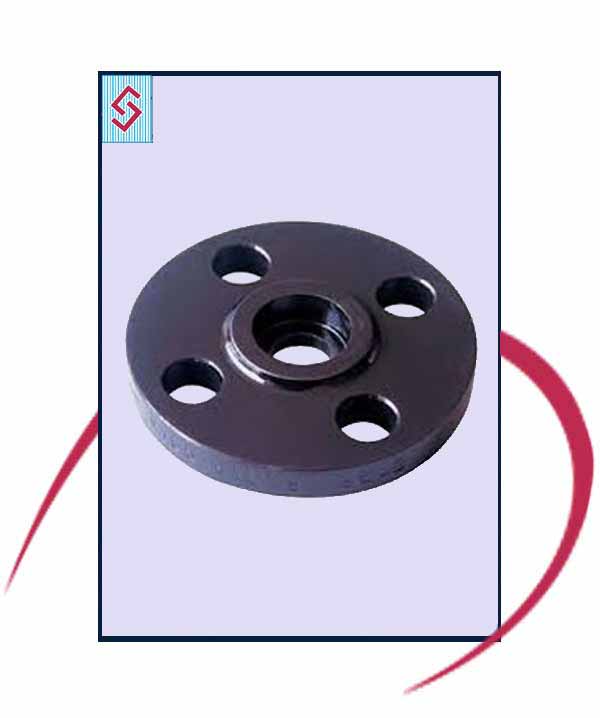

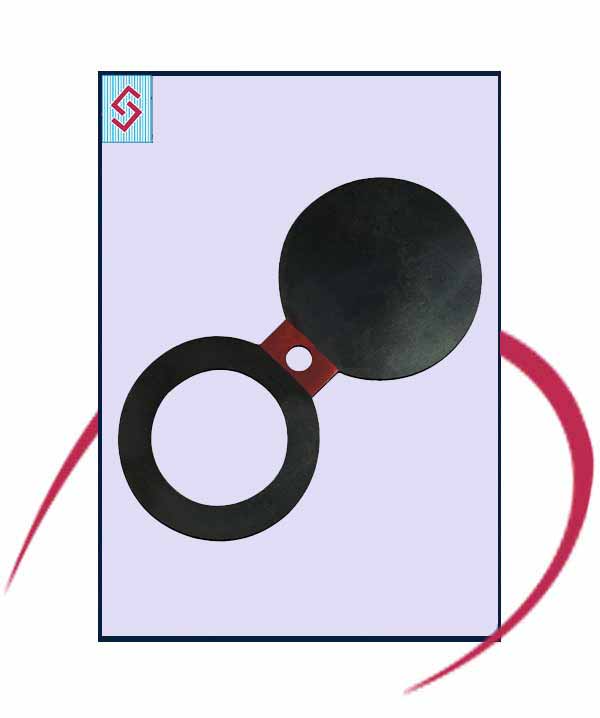

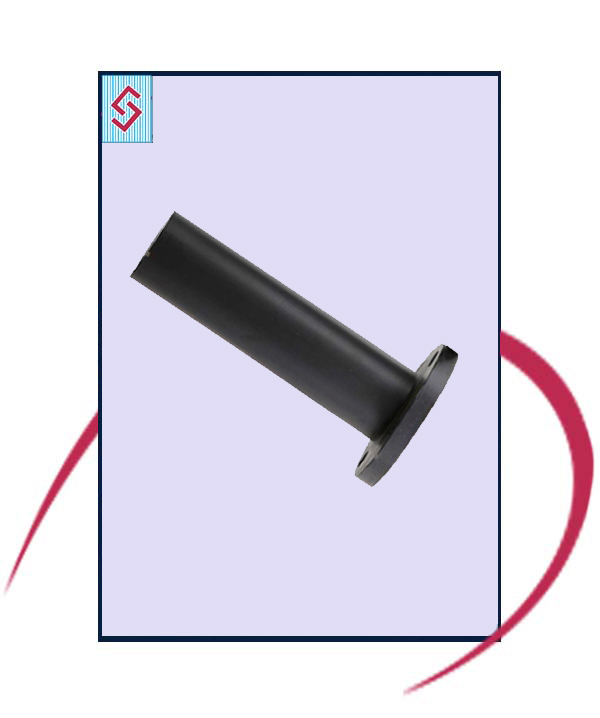

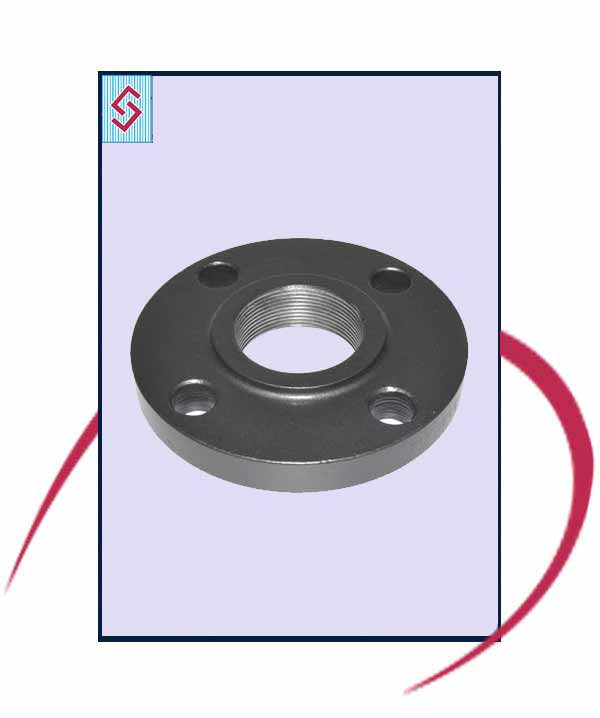

Steel Sales Co. belongs among the highly-esteemed firms specializing in the production and export of top-class metal and alloy products, among which is the alloy steel A182 F5 flanges. After we have accomplished manufacturing the rich-quality products, they are carefully packaged in a manner that retains their quality and keeps them safe throughout the transportation process. All the methods involved in production and export are done in accordance with the national and international norms and guidelines.

The chemical composition of the alloy steel flanges belonging to the grade A182 F5 flanges plays a crucial role in the physical and chemical attributes expertly exhibited by them. The elements which primarily contribute majorly to the properties of the flanges are chromium and molybdenum. The combination of these two elements is what grants the flanges superior corrosion resistance properties, for which the flanges in consideration are widely known. Apart from these elements, the presence of additional elements such as silicon, sulfur, manganese, carbon, and phosphorus stabilizes the flanges as a whole while also imparting additional features. For instance, carbon contributes towards the hardness and toughness displayed by the flanges.

The key trait of the alloy steel A182 F5 flanges is the resistance it exhibits against corrosive agents. They are known to display resistance against an impressive range of corrosive liquids and gases which could otherwise harm the physical and chemical structure of the flanges. The resistance they display against corrosion is extended to also include the heat resistance they possess against soaring temperatures. This heat resistance enables them to stay strong even as the temperatures are rapidly increasing far more than the standard conditions. Strength is another distinct feature manifested by the flanges, against any form of mechanical strain or pressure faced by them during harsh operating conditions. With all the above-mentioned properties, coupled with stability, durability, flexibility, and many more features exhibited by the A182 F5 flanges, they are a common choice for many applications

Several industries have adopted the alloy steel flanges of the grade A182 F5 flanges in their operations and have been profiting ever since. The industries and applications in which these flanges are utilized are pharmaceuticals, oil and gas processing, food industry, pulp, and paper industry, power plants, etc.

Tests on every product are conducted regularly and as per the necessary guidelines after which suitable certificates are provided and the products are shipped off with the attached certificates, verifying the results of the tests.

Standard Specification

| STANDARD | WERKSTOFF NR. | UNS |

| Alloy Steel F5 | 1.7362 | K41545 |

| Grade | C | si | mn | s | P | Cr | Mo |

| Alloy Steel F5 | 0.15 max | 0.5 max | 0.3 – 0.6 | 0.03 | 0.03 | 4 – 6 | 0.044 – 0.65 |

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min |

| Alloy Steel F5 | 275 | 485 | 20 |

Turkey, Mexico, Angola, Serbia, Jordan, Indonesia, Iran, United States, Qatar, Iran, South Korea, Thailand, Mongolia, Russia, Kenya, Bahrain, Netherlands, Bhutan, Trinidad & Tobago, Sri Lanka, Kuwait, Tunisia, Poland, Ecuador, Yemen, Venezuela, Philippines, Ukraine, Bolivia, Chile, Belarus, Egypt, Norway, Chile, Ghana, Morocco, Argentina, Azerbaijan, South Africa, Portugal, Italy, United Arab Emirates, Romania, Hong Kong, Switzerland, Australia, Costa Rica, Taiwan, Afghanistan, Bulgaria, Israel, Gabon, Austria, Lebanon, China, Singapore, New Zealand, Spain, Croatia, France, Brazil, Kazakhstan, Japan, Colombia, Pakistan, Saudi Arabia, Peru, Greece, Algeria, Libya, United Kingdom, Slovakia, Sweden, Mexico, Vietnam, Denmark, Hungary, Estonia, Malaysia, Poland, Czech Republic, Lithuania, Nigeria, Nigeria, Iraq, Oman, Bangladesh, Finland, Belgium, Canada.

Brisbane, Dubai, Jamshedpur, Manama, Sydney, Melbourne, Chandigarh, Dammam, Lagos, Surat, Kolkata, Nagpur, Al Jubail, Ahvaz, Kuwait City, Riyadh, Lahore, Colombo, Aberdeen, Mumbai, New York, Secunderabad, Muscat, Jeddah, Thane, Baroda, Ludhiana, Ankara, Calgary, Istanbul, Ahmedabad, Indore, Courbevoie, Ernakulam, Abu Dhabi, Visakhapatnam, Toronto, Haryana, Coimbatore, Montreal, Kuala Lumpur, Kanpur, Thiruvananthapuram, Edmonton, Dallas, Caracas, Milan, Granada, Algiers, Jakarta, Ranchi, Pune, Madrid, Al Khobar, Navi Mumbai, Rio de Janeiro, Port-of-Spain, Hanoi, Gimhae-si, Noida, Vadodara, Busan, Chennai, Doha, Bengaluru, Perth, Chiyoda, Bangkok, Sharjah, Pimpri-Chinchwad, Hyderabad, La Victoria, Los Angeles, Petaling Jaya, Cairo, New Delhi, Bhopal, Seoul, Houston, Faridabad, Rajkot, Ho Chi Minh City, Bogota, Santiago, Tehran, Ulsan, Howrah, Vung Tau, Jaipur, Atyrau, Geoje-si, Gurgaon, Nashik.

MATERIALS

PRODUCTS

Express Delivery

We understand the urgency of product requirement for Oil & Gas Industry & industrial breakdowns at various situations attenuating the project performance.

Our Certifications